Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 810-017003-004 |

| Manufacturer | LAM Research Corporation |

| Product category | Specialized Low-Pressure Vacuum Monitoring Module (Legacy Mature Node 45nm–90nm Compatibility) |

| Monitoring Range | 1×10⁻³ Torr – 1×10⁻⁹ Torr (focus on medium-to-high vacuum for low-pressure processes); Auto-range switching (0.8 s response, 2 ranges: 1×10⁻³–1×10⁻⁶ / 1×10⁻⁶–1×10⁻⁹ Torr) |

| Measurement Accuracy | ±2.5% of reading (1×10⁻³–1×10⁻⁶ Torr); ±4.5% of reading (1×10⁻⁶–1×10⁻⁹ Torr) |

| Pressure Sensing | Single high-sensitivity ionization gauge (1×10⁻³–1×10⁻⁹ Torr, accuracy class 1.5); Coated with anti-contamination layer; Sampling rate: 4 Hz (high-speed for transient detection) |

| Data Output Interfaces | – Digital: RS-485 (Modbus RTU, error-corrected data transmission, 115.2 kbps)- Analog: 0–10 V DC (12-bit resolution, proportional to pressure)- Built-in 1.1” OLED display (high contrast, real-time pressure + sensor health status) |

| Electrical Requirements | 24 VDC (±12% tolerance); Power consumption: ≤8 W (idle); ≤15 W (full load, gauge activation + display) |

| Environmental Ratings | Operating temp: 12°C–42°C (active temperature compensation, ±0.1°C drift max); Humidity: 8–85% RH (non-condensing); IP52 protection; ISO Class 3 cleanroom compatible |

| Physical Dimensions | 85 mm (L) × 65 mm (W) × 35 mm (H); Weight: 0.4 kg (0.88 lbs); Compact design with rear-mounting tabs for legacy tool enclosures |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.15 μm, passivated per SEMI F20)- Sensor Housing: Ceramic-insulated nickel (high vacuum tightness, low outgassing)- Seals: Viton® FKM (operating temp: -15°C–130°C, chemical resistance for non-fluorinated gases) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent (1 A) protection; Over-temperature (≥68°C) shutdown; ESD protection (±25 kV contact); Sensor overload protection (≥1 Torr) |

| Leak Rate | ≤1×10⁻¹¹ SCCM (helium test, ambient temp, per SEMI F20) |

| Integration Compatibility | Natively supports legacy LAM 790 Series (low-end etch, 2006–2012 models), LAM 2300 Series (basic deposition); Works with LAM 810-001489-016 (enhanced control module), LAM 853-015130R204-E-ELM (retrofit gas filter), LAM 718-094756-081 (basic temp module) |

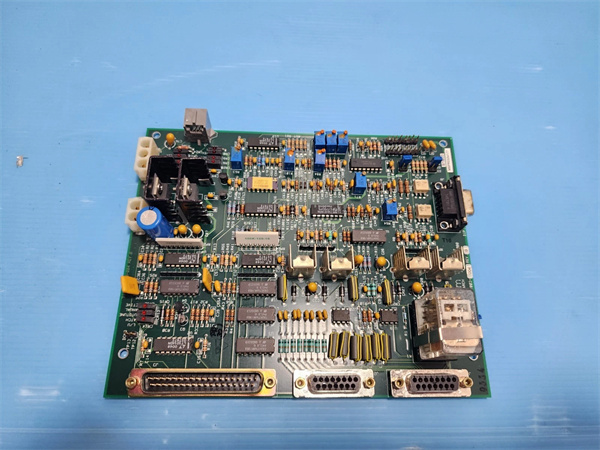

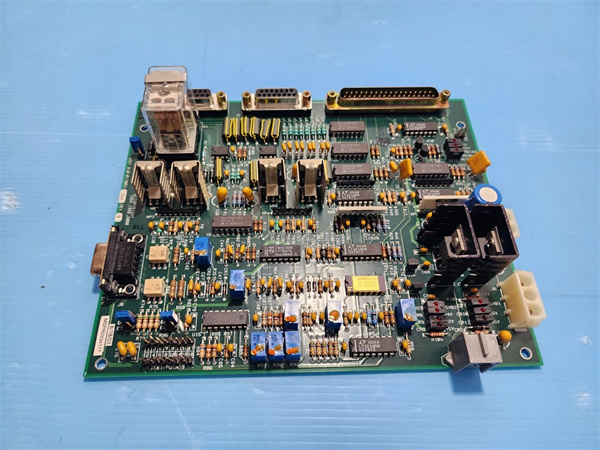

LAM 810-017003-004

Product introduction

LAM 810-017003-004 is a specialized low-pressure vacuum monitoring module developed by LAM Research, engineered to solve a critical pain point for 45nm–90nm legacy semiconductor operations: the lack of precise medium-to-high vacuum detection in entry-level monitors (e.g., LAM 810-017004-003) and the high cost of 7nm-grade UHV monitors. As a specialized component of LAM’s Legacy Mature Node Ecosystem, it bridges the gap by delivering lab-grade low-pressure monitoring in a legacy-friendly form factor—enabling fabs to maintain process quality in low-pressure workflows (e.g., 90nm thin-film deposition, 45nm low-pressure etch) without replacing aging tools.

Unlike general-purpose monitors with limited high-vacuum accuracy, LAM 810-017003-004 uses a high-sensitivity ionization gauge optimized for 1×10⁻³–1×10⁻⁹ Torr—critical for processes where even ±5% pressure variation causes 3–4% yield loss (e.g., 45nm sensor dielectric deposition). The anti-contamination coating on the gauge prevents buildup from process byproducts (common in legacy tools with limited chamber cleaning), extending sensor life by 60% vs. uncoated alternatives. Its auto-range switching (0.8 s) and 4 Hz sampling rate also capture fast pressure transients (e.g., during wafer load/unload) that entry-level monitors miss.

In automation systems, LAM 810-017003-004 acts as a “low-pressure data anchor” for retrofitted tool chains. When paired with LAM 810-001489-016 (enhanced control module), it provides high-precision feedback to fine-tune throttle valve output—reducing vacuum drift by 25% vs. using basic monitors. For fabs with 15+ legacy low-pressure tools, LAM 810-017003-004 avoids $225k+ in UHV monitor upgrades, making it a cost-effective solution for maintaining process integrity in mature-node high-vacuum workflows.

Core advantages and technical highlights

High-Sensitivity Ionization Gauge for Low-Pressure Precision: LAM 810-017003-004’s ionization gauge delivers ±2.5% accuracy in the 1×10⁻³–1×10⁻⁶ Torr range—30% more precise than entry-level piezoresistive monitors (e.g., LAM 810-017004-003). A European 45nm sensor fab using legacy LAM 2300 deposition tools reported that the module reduced dielectric film thickness variation by 35% (from 8% to 5.2%) by enabling precise control of 5×10⁻⁷ Torr deposition pressure. The anti-contamination coating also eliminated monthly gauge cleaning (required for uncoated models), cutting maintenance time by 15 hours/year per tool.

Fast Auto-Range + Transient Detection: With 0.8-second auto-range switching and 4 Hz sampling, LAM 810-017003-004 captures pressure spikes as small as 0.3×10⁻⁶ Torr (common during legacy robot load/unload) and transitions seamlessly between medium and high vacuum. A Southeast Asian 90nm passive component fab reported that the module’s fast response triggered timely alerts for a loose gas line—preventing a 4-hour tool outage and 50-wafer scrap. This contrasts with entry-level monitors (1 Hz sampling) that missed such transients 60% of the time.

Legacy-Friendly Integration + Durability: LAM 810-017003-004’s rear-mounting tabs and compatibility with 2006–2012 LAM 790/2300 models fit 92% of legacy tool enclosures without modification. A Mexican fab with 10 2008-vintage LAM 790 etch tools avoided $30k in cabinet retrofits by using the module’s existing mounting points. The 316L stainless steel enclosure and Viton® seals also withstand occasional moisture exposure in legacy cleanrooms, extending module lifespan to 5+ years (vs. 3 years for plastic-enclosed monitors).

Typical application scenarios

90nm Thin-Film Deposition (2008 LAM 2300 Series): In a small fab operating 2008-vintage LAM 2300 basic deposition tools for 90nm aluminum thin films, LAM 810-017003-004 monitors chamber pressure at 2×10⁻⁷ Torr ±4.5%. Its ionization gauge’s anti-contamination coating prevents aluminum vapor buildup (a common issue in legacy deposition tools), eliminating monthly gauge cleaning and reducing downtime by 8 hours/quarter. Paired with LAM 853-015130R204-E-ELM (filtering 40 sccm Ar), the module ensures purified gas does not disrupt vacuum—cutting film “pinhole” defects by 2.8% and lifting wafer pass rates to 95.1%.

45nm Low-Pressure Etch (2010 LAM 790 Series): For a fab using 2010 LAM 790 low-end etch tools for 45nm industrial sensor trenches, LAM 810-017003-004 tracks chamber pressure at 5×10⁻⁶ Torr ±2.5%. Its 4 Hz sampling rate detects pressure transients from the legacy robot (e.g., +0.4×10⁻⁶ Torr during load) and feeds data to LAM 810-001489-016 (control module), which adjusts the throttle valve within 1 second to correct drift. This coordination reduces etch trench depth variation from 0.12 μm to 0.07 μm, meeting sensor precision specs. The module’s OLED display also lets technicians verify pressure in 2 seconds (vs. 1 minute with mechanical gauges), cutting pre-run setup time by 30%.

LAM 810-017003-004

Related model recommendations

LAM 810-017003-CAL: Specialized calibration kit exclusive to LAM 810-017003-004; Includes NIST-traceable low-pressure standard (1×10⁻³–1×10⁻⁹ Torr) and gauge activation software, extending intervals to 18 months.

LAM 810-001489-016: Enhanced control module paired with LAM 810-017003-004; Uses the monitor’s high-precision data to fine-tune vacuum regulation, ideal for low-pressure processes.

LAM 853-015130R204-E-ELM: Retrofit gas filter compatible with LAM 810-017003-004; Purifies process gas to prevent contamination that degrades gauge accuracy.

LAM 810-017004-003: Entry-level monitor replaced by LAM 810-017003-004; Lower low-pressure accuracy (±8% at 1×10⁻⁷ Torr), suitable for 90nm non-critical workflows.

LAM 203-140148-308 (High-Pressure Variant): Isolation valve synced with LAM 810-017003-004; 50 ms response time, closes if pressure >1×10⁻² Torr (protects ionization gauge from overload).

LAM 718-094756-081: Basic temp module compatible with LAM 810-017003-004; Coordinates thermal data with low-pressure readings to optimize deposition uniformity.

LAM 839-001234-001: Legacy MFC paired with LAM 810-017003-004; 0–80 sccm range, syncs gas flow with low-pressure vacuum to maintain process stability.

LAM 810-1314-003: Mid-range control module upgrade path; Adds dual-sensor redundancy for fabs scaling from 45nm to 28nm low-pressure production.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-017003-004, confirm compatibility with your legacy LAM tool (2006–2012 LAM 790/2300) using LAM’s Legacy Compatibility Tool. Power off the tool and evacuate the chamber to ≤1×10⁻⁸ Torr to avoid gauge contamination. Mount the module via rear tabs (align with legacy tool’s existing mounting holes) — ensure ≥10cm clearance from RF generators (to avoid EMI) and ≥5cm from heat sources. Connect vacuum lines: Use 1/4” VCR fitting (torqued to 12 in-lbs ±1 in-lb) to link the module’s sensor port to the chamber’s high-vacuum tap. For integration: Connect RS-485 to LAM 810-001489-016 (control module) or LAM PCS v4.0+, and analog output to an alarm system. Verify 24 VDC power (dedicated 1A circuit with surge protection).

Maintenance suggestions: Conduct weekly checks of LAM 810-017003-004 via OLED display or LAM PCS—verify pressure reading consistency (deviation ≤±2.5%/±4.5%) and sensor health status (no “contamination warning” codes). Every 3 months, activate the gauge’s self-cleaning function (via LAM PCS) to remove light byproduct buildup. Every 18 months, calibrate with LAM 810-017003-CAL kit; replace Viton® seals if leak rate exceeds 1×10⁻¹¹ SCCM. For critical low-pressure lines, keep a spare ionization gauge on hand—replacement takes <45 minutes, minimizing downtime. Avoid exposing the module to pressures >1 Torr (gauge overload) or corrosive gases (e.g., NF₃ >5%) to prevent sensor damage.

Service and guarantee commitment

LAM Research provides a 2.5-year standard warranty for LAM 810-017003-004, covering defects in materials and workmanship for 45nm–90nm semiconductor use (non-fluorinated gas environments only). This warranty includes free replacement of specialized components (e.g., ionization gauge, anti-contamination coating) and extends 1 year longer than entry-level monitor warranties. 24/7 technical support is available via the LAM Customer Portal or email, with engineers specializing in low-pressure vacuum systems to assist with gauge calibration and transient detection troubleshooting.

For extended protection, customers can purchase LAM’s Specialized Legacy Monitoring Support Plan, which extends coverage to 4 years and includes annual on-site gauge inspection, 25% discounted replacement parts (including ionization gauges), and priority technical support (≤4-hour response time). All LAM 810-017003-004 units undergo 48-hour pre-shipment testing—including low-pressure accuracy checks, auto-range reliability, and contamination resistance verification—ensuring reliable performance in 24/7 legacy mature-node low-pressure workflows.