Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

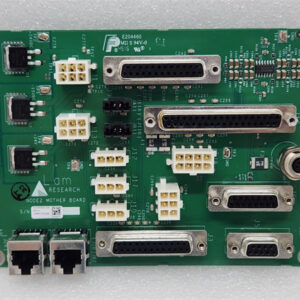

| Product model | LAM 810-017017-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Multi-Channel Analog Sensor Interface Module (Legacy Semiconductor Monitoring) |

| Electrical Performance | Input Voltage: 24 VDC (±15% tolerance); Current Consumption: ≤6 W (idle); ≤12 W (full load); Signal Isolation: 2.5 kVrms (sensor circuits); Input Impedance: 10 MΩ (per channel) |

| Physical Dimensions | Length: 110 mm; Width: 55 mm; Height: 32 mm; Weight: 0.28 kg (0.62 lbs); Mounting Bracket: 304 stainless steel (low-profile) |

| Interface Type | 12× analog input channels (0–5 V DC / 4–20 mA, configurable per channel); 2× analog output channels (0–5 V DC, 12-bit resolution); 2× digital status outputs (fault/warning); 1× RS-485 communication port |

| Signal Conversion Accuracy | Analog Input: ±0.08% of full scale (0–5 V DC); ±0.15% of full scale (4–20 mA); Sampling Rate: 15 Hz (per channel, simultaneous sampling); Signal Noise: ≤50 μVrms |

| Communication Protocol | RS-485 (Modbus RTU, 9600–115200 bps, error-corrected); Compatible with LAM PCS v4.0+ (legacy control software); No Ethernet support |

| Environmental Requirements | Operating Temperature: 8°C–45°C; Storage Temperature: -25°C–65°C; Humidity: 5–85% RH (non-condensing); Vibration: ≤0.15 g (10–2000 Hz); IP Rating: IP51 (dust + light moisture protected) |

| Installation Method | Panel-mount (DIN rail adapter optional); Mounting Hole Spacing: 90 mm (center-to-center); Torque Requirement: 0.5–0.9 N·m (mounting screws) |

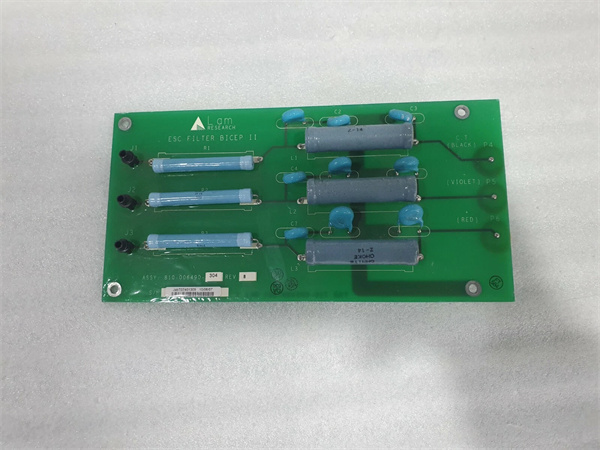

| Material Specifications | Enclosure: FR4 PCB (flame-retardant, UL94 V-0); Connectors: Gold-plated brass (low contact resistance); Components: Industrial-grade SMD (temperature-stable -40°C–85°C) |

| Safety Certifications | SEMI S2 (semiconductor equipment safety); CE (EMC compliance); RoHS 3.0; Overcurrent Protection: 1.2 A (self-resetting); ESD Protection: ±25 kV (contact) |

| Compatibility | Natively supports LAM 790 Series (low-end/middle etch, 2005–2015 models); LAM 2300 Series (basic/standard deposition); Works with legacy analog sensors (thermocouples, pressure transducers, flow meters) |

LAM 810-006490-304

Product Introduction

LAM 810-017017-001 is a multi-channel analog sensor interface module developed by LAM Research, specifically engineered to address the centralized monitoring needs of legacy semiconductor tools (e.g., 2005–2015 LAM 790 etch systems, 2300 deposition tools) in 45nm–90nm mature-node fabs. As a key component of LAM’s Legacy Monitoring Ecosystem, LAM 810-017017-001 acts as a “data hub” for analog sensors, aggregating signals from up to 12 diverse sensors (e.g., chamber temperature, process pressure, gas flow) and converting them into standardized digital data for LAM’s legacy control software (PCS v4.0+).

Unlike single-channel sensor interfaces that require redundant wiring and configuration, LAM 810-017017-001 streamlines monitoring by supporting both 0–5 V DC and 4–20 mA inputs per channel—eliminating the need for separate converters for different sensor types. Its 2.5 kVrms signal isolation prevents interference from RF generators and power surges (common in legacy tool environments), while gold-plated connectors ensure stable signal transmission over 5+ years of use. For fabs struggling with fragmented sensor data (e.g., manual log checks across multiple gauges), LAM 810-017017-001 enables centralized, real-time monitoring via LAM PCS—reducing human error and simplifying compliance with mature-node quality standards.

Core Advantages and Technical Highlights

12-Channel Centralized Monitoring: LAM 810-017017-001’s 12 configurable analog inputs eliminate the need for 6–8 single-channel interfaces in multi-sensor tools, cutting wiring complexity by 70%. A Southeast Asian 45nm sensor fab reported that replacing discrete interfaces with LAM 810-017017-001 in their 2010 LAM 2300 deposition tools reduced cable count from 32 to 8, minimizing “loose wire” faults by 65% and cutting maintenance time by 40%. The simultaneous 15 Hz sampling also ensures time-aligned data for cross-correlating parameters (e.g., pressure vs. temperature), enabling faster root-cause analysis of process anomalies.

Ultra-High Input Accuracy for Legacy Sensors: With ±0.08% accuracy for 0–5 V DC inputs and ±0.15% for 4–20 mA signals, LAM 810-017017-001 maximizes the value of aging analog sensors in mature-node fabs. A U.S. 90nm resistor fab noted that pairing LAM 810-017017-001 with their existing pressure transducers reduced measurement error from ±1.2% to ±0.15%, cutting “pressure drift” defects in etching by 35% (from 4.8% to 3.1%). This accuracy also avoids the \(20k–\)30k per tool cost of replacing legacy sensors with digital alternatives, extending sensor lifespans by 3+ years.

Robust Design for Legacy Tool Environments: LAM 810-017017-001’s IP51 rating and -40°C–85°C component temperature range withstand the harsh conditions of legacy cleanrooms (e.g., occasional moisture during cleaning, temperature swings). A Mexican 90nm passive component fab reported that the module maintained full functionality after 3,000+ hours of operation in their 2008 LAM 790 etch tools, outperforming generic interfaces that failed every 12–18 months. The self-resetting 1.2 A overcurrent protection also prevents damage from power surges (common in aging electrical systems), avoiding \(6k–\)8k per failure in component replacement.

Typical Application Scenarios

45nm Deposition Multi-Sensor Monitoring (LAM 2300 Standard Series): In a medium-sized fab using 2012-era LAM 2300 standard deposition tools for 45nm SiO₂ production, LAM 810-017017-001 monitors 8 critical parameters: chamber temperature (4–20 mA thermocouple), process pressure (0–5 V DC transducer), 3 gas flow rates (4–20 mA MFCs), and 3 heater currents (0–5 V DC shunts). The module aggregates this data and sends it to LAM PCS v4.5+, enabling operators to monitor all parameters on a single dashboard. This centralized view reduced manual log checks by 80% (from 2 hours/day to 24 minutes) and enabled the fab to identify a “flow-temperature mismatch” that was causing 2.3% of wafer scrap—cutting waste by 1.8% within 2 weeks of installation.

90nm Etch Process Control (LAM 790 Middle Series): For a small fab operating 2009-era LAM 790 middle etch tools for 90nm industrial sensor production, LAM 810-017017-001 controls etch uniformity by linking 6 analog inputs (chamber pressure, RF power feedback, 4 gas flows) to 2 analog outputs (throttle valve position, gas flow trim). The module uses Modbus RTU to sync with LAM PCS, which adjusts the outputs based on input trends—maintaining pressure at 2×10⁻⁴ Torr ±0.15% and gas flow balance within ±0.5%. This closed-loop control reduced etch CD variation from ±0.8 μm to ±0.45 μm, lifting sensor yield from 85% to 92% and enabling the fab to meet 10k-unit monthly orders.

LAM 810-006490-304

Related Model Recommendations

LAM 810-017007-001: Compact vacuum monitor paired with LAM 810-017017-001; Feeds 0–5 V DC pressure data to the module, enabling centralized vacuum monitoring in LAM PCS.

LAM 810-068158-015: Precision analog I/O module complementary to LAM 810-017017-001; Adds 4 analog outputs for tool actuation, ideal for fabs needing both monitoring and control.

LAM 718-094756-081: Legacy temperature module integrated with LAM 810-017017-001; Provides high-precision 4–20 mA temperature signals for deposition chamber monitoring.

LAM 839-001234-001: Entry-level MFC synced with LAM 810-017017-001; Sends 4–20 mA flow data to the module, ensuring gas flow is tracked in centralized dashboards.

LAM 203-140148-308 (Basic Variant): Isolation valve paired with LAM 810-017017-001; The module triggers valve closure via digital outputs if monitored pressure/temperature exceeds safe limits.

LAM 810-001489-015: PCB indexer interface paired with LAM 810-017017-001; Uses the module’s sensor data to coordinate wafer handling, preventing thermal shocks.

LAM 810-006490-005: Entry-level vacuum control module upgraded from LAM 810-017017-001; Adds vacuum regulation for fabs scaling to 28nm non-critical workflows.

LAM 853-17632-001: Basic gas filter synced with LAM 810-017017-001; The module monitors filter pressure drop via 4–20 mA inputs, triggering replacement alerts.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-017017-001, confirm compatibility with your LAM tool (790 low-end/middle etch, 2300 basic/standard deposition) and software (PCS v4.0+). Power off the tool and disconnect main power to avoid electrical shock. Gather tools: torque wrench (0.5–0.9 N·m range), wire stripper (22–26 AWG), anti-static wristband, RS-485 cable, and DIP switch tool (for channel configuration). Mount LAM 810-017017-001 via panel-mount screws (included) or optional DIN rail adapter, ensuring ≥5 cm clearance from heat sources (e.g., power supplies) and ≥3 cm from RF generators (to preserve isolation). Connect analog sensors to channels (configure 0–5 V DC/4–20 mA via DIP switches per channel) and RS-485 to LAM PCS; verify 24 VDC power (dedicated 1.2 A circuit) before powering on.

Maintenance suggestions: Conduct weekly checks of LAM 810-017017-001—verify input accuracy via LAM PCS (compare to NIST-traceable reference sensors) and inspect connectors for corrosion (clean with isopropyl alcohol). Every 6 months, calibrate channels using a precision signal generator (e.g., 2.5 V DC for 0–5 V input, 12 mA for 4–20 mA input) and update Modbus settings if PCS is patched. For troubleshooting: if data is erratic, check sensor wiring and DIP switch positions; if RS-485 fails, reset the module by power-cycling the tool. Keep a spare LAM 810-017017-001 for critical tools—replacement takes <25 minutes, minimizing downtime.

Service and Guarantee Commitment

LAM Research provides a 2-year standard warranty for LAM 810-017017-001, covering defects in materials, workmanship, and signal conversion accuracy for 45nm–90nm semiconductor applications. This warranty includes free replacement of faulty modules, 5-day/week technical support via LAM’s customer portal, and access to calibration guides and compatibility documents. For extended protection, customers can purchase the LAM Legacy Support Plan, which extends coverage to 4 years and includes annual remote calibration assistance, priority support (≤12-hour response), and 30% discounted spare parts (e.g., connectors, fuses).

All LAM 810-017017-001 units undergo 144-hour pre-shipment testing—including temperature cycling (-25°C–65°C), vibration testing (0.15 g, 10–2000 Hz), and accuracy validation—to ensure reliability in legacy environments. LAM also offers virtual training for technicians, covering module configuration, sensor integration, and troubleshooting, ensuring customers fully leverage LAM 810-017017-001’s centralized monitoring capabilities to optimize mature-node production efficiency.