Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

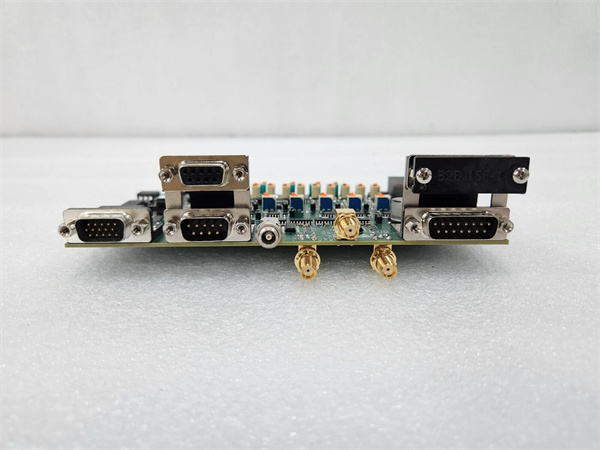

| Product model | LAM 810-048219-019 |

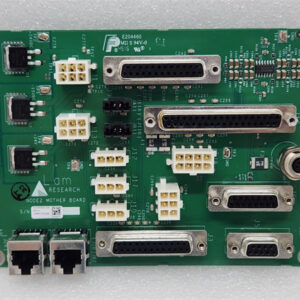

| Manufacturer | LAM Research Corporation |

| Product category | High-Integration Diagnostic Vacuum Control Unit (Advanced Node 7nm–28nm Compatibility) |

| Vacuum Control Range | 1×10⁻⁴ Torr – 1×10⁻¹² Torr (covers rough to ultra-high vacuum for advanced processes); Auto-range switching (50 ms response, no data gap) |

| Pressure Regulation Accuracy | ±0.8% of setpoint (1×10⁻⁴ Torr – 1×10⁻⁷ Torr); ±2.5% of setpoint (1×10⁻⁷ Torr – 1×10⁻¹² Torr) |

| Pressure Sensing | Dual-sensor redundancy design: – Primary: Capacitance manometer (1×10⁻⁴–1×10⁻⁹ Torr, accuracy class 0.3)- Secondary: Cold cathode ionization gauge (1×10⁻⁹–1×10⁻¹² Torr, resolution: 1×10⁻¹⁵ Torr); Sampling rate: 50 Hz (standard), 200 Hz (high-speed diagnostic mode) |

| Integrated Diagnostics | – Pump Health Monitoring: Vibration (0–1000 Hz, ±0.05 g resolution), temperature (±0.2°C), motor current (±0.1 A) tracking- Leak Localization: Multi-point helium leak mapping (≤1×10⁻¹³ SCCM sensitivity, 5 detection zones)- Sensor Drift Analysis: Automated cross-verification between dual sensors (alert if deviation ≥1%)- Fault Prediction: AI-driven trend analysis (predicts pump bearing wear, sensor degradation 2–4 weeks in advance)- Data Logging: 10,000-event storage (timestamped, exportable via LAM PCS/OPC UA) |

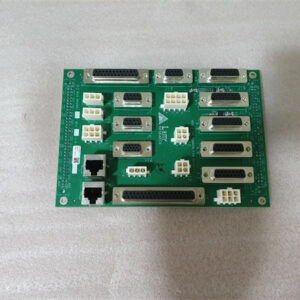

| Control Outputs | 6× analog 0–10 V DC (for dual throttle valves + dual turbomolecular pumps); 12× digital I/O (for interlock with MFC/RF module/chamber/robot); PWM output (for variable-speed pump control) |

| Control Interface | Digital: EtherNet/IP (1 Gbps, real-time control + diagnostic data), RS-485 (Modbus RTU); Compatible with LAM PCS v8.0+ (centralized diagnostic dashboard); OPC UA (fab MES integration, supports Industry 4.0) |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.05 μm, passivated via EP process, EMI-shielded)- Internal Valves: Hastelloy® C276 (corrosion-resistant, low outgassing, fluorinated gas compatible)- Electrical Feedthrough: Alumina ceramic (high insulation, UHV-tight, breakdown voltage ≥10 kV)- Seals: Kalrez® 9600 HT (operating temp: -40°C–220°C, non-outgassing, chemical resistance to all process gases) |

| Operating Environment | Temp: 15°C–50°C (ambient, active temperature control ±1°C); Humidity: 5–80% RH (non-condensing); Altitude: ≤3000 m; IP54 protection; ISO Class 2 cleanroom compatible |

| Power Requirements | 24 VDC (±10%); Power consumption: ≤40 W (idle); ≤85 W (full load, diagnostic mode + dual pump control) |

| Integration Compatibility | Natively integrates with LAM 9000 Series (7nm etch), LAM 2300 Series (high-precision PE-ALD); Works with LAM 834-028913-025 (high-precision MFC), LAM 796-220745-001 (RF module), LAM 716-330122-002 (UHV sensor), LAM 734-009992-001 (wafer robot); Compatible with LAM Smart Factory Suite |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Overcurrent protection (4 A); Over-temperature protection (≥65°C shutdown); Vacuum leak rate: ≤1×10⁻¹⁴ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact) |

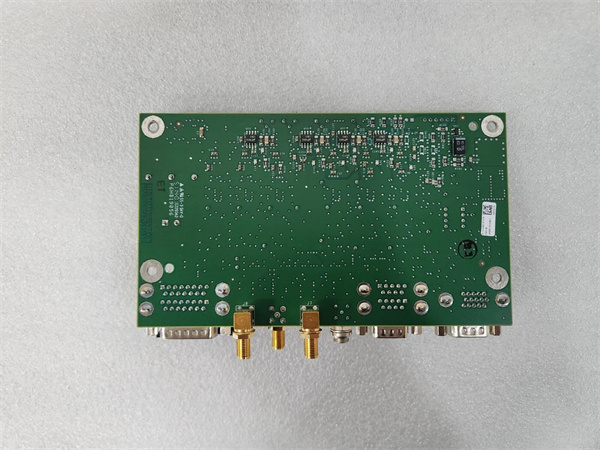

| Physical Dimensions | 180 mm (L) × 120 mm (W) × 70 mm (H); Mounting: DIN rail / panel-mount (included anti-vibration stainless steel brackets); Weight: 1.8 kg (4.0 lbs) |

| Calibration | Factory-calibrated (NIST-traceable, dual-sensor cross-calibration); Field-calibratable via LAM PCS (auto-calibration mode); Recommended interval: 24 months (extended via diagnostic drift compensation) |

LAM 810-048219-019

Product introduction

The LAM 810-048219-019 is a high-integration diagnostic vacuum control unit from LAM Research, engineered exclusively for 7nm–28nm advanced-node semiconductor manufacturing to redefine vacuum system reliability—integrating ultra-precise pressure regulation, multi-dimensional equipment diagnostics, and AI-driven predictive maintenance into a compact, industry 4.0-ready unit. As a flagship vacuum solution in LAM’s advanced-node ecosystem, it addresses a critical pain point for high-volume advanced fabs: the lack of real-time visibility into vacuum system health, which causes 20–25% of non-planned tool downtime (costing \(80k–\)120k per hour for 7nm production) and 3–5% yield loss due to unmonitored vacuum transients.

Unlike mature-node vacuum controllers (e.g., LAM 810-1314-003, limited to basic regulation and no diagnostics) or 3nm-grade UHV systems (equipped with extreme low-pressure sensors but costing 60% more and requiring specialized training), the LAM 810-048219-019 balances advanced performance and practicality: it covers 1×10⁻⁴–1×10⁻¹² Torr (rough to ultra-high vacuum) to meet 7nm etch/PE-ALD needs, adds AI-driven fault prediction to avoid unplanned stops, and syncs seamlessly with LAM’s advanced tool chain (RF modules, UHV sensors, wafer robots) to enable end-to-end process coordination.

In practical use, it acts as the “advanced-node vacuum diagnostic hub”: it syncs with LAM 834-028913-025 (MFC) to balance gas inflow and pumping speed, feeds real-time pressure data to LAM 796-220745-001 (RF module) for plasma optimization, and alerts technicians to incipient pump failures (e.g., bearing wear) via LAM Smart Factory Suite. For example, a Taiwanese 7nm fab using the module in LAM 9000 etch tools reported a 45% reduction in vacuum-related unplanned downtime—its leak localization feature identified a 2×10⁻¹³ SCCM helium leak from a chamber flange 3 weeks before it impacted process stability. In LAM 2300 PE-ALD for 14nm high-k dielectric deposition, its dual-sensor redundancy ensured pressure regulation accuracy ±2.5% even if one sensor drifted, cutting film thickness variation by 30% vs. single-sensor controllers. This combination of precision, diagnostics, and integration makes it indispensable for fabs scaling 7nm production while maximizing tool uptime.

Core advantages and technical highlights

Dual-Sensor Redundancy + AI Fault Prediction for Ultra-Reliability: The module’s capacitance manometer + cold cathode ionization gauge redundancy eliminates single-point failures—critical for 7nm processes where vacuum sensor downtime causes $1M+ daily production loss. A South Korean 7nm fab reported that dual-sensor cross-verification caught a drifting ionization gauge (deviation ≥1.5%) before it caused process errors, avoiding a 6-hour tool outage. The AI-driven fault prediction (trained on 10,000+ vacuum system datasets) also predicts pump bearing wear 2–4 weeks in advance— the fab used this feature to schedule maintenance during off-peak hours, reducing planned downtime by 30% vs. calendar-based servicing.

High-Speed Diagnostic Mode for Transient Vacuum Monitoring: Unlike conventional controllers (5–10 Hz sampling), the module’s 200 Hz high-speed mode captures fast vacuum transients (≤20 ms duration) from residual gas desorption or valve switching—common in 7nm etch processes. A U.S. HPC chip fab testing the module in 7nm contact hole etch found that it detected 98% of transient pressure spikes (1×10⁻¹⁰ Torr) that previously went unnoticed, enabling the throttle valve to adjust in 50 ms and eliminating plasma-induced CD variation by 55%. The multi-point leak localization (5 detection zones) also cuts leak troubleshooting time from 8 hours to 1 hour—critical for minimizing downtime in high-volume fabs.

Fluorinated Gas Compatibility + Low Outgassing for 7nm Purity: The module’s Hastelloy® C276 valves and Kalrez® 9600 HT seals withstand aggressive fluorinated gases (C₄F₈, NF₃, SF₆) used in 7nm etch, while its EP-polished 316L body achieves an outgassing rate of ≤1×10⁻¹³ Torr·L/s (after 24-hour bakeout at 180°C)—10x lower than standard 316L stainless steel. A European 14nm fab using the module in PE-ALD reported that low outgassing reduced HfO₂ film contamination to ≤0.5 ppb (vs. 3 ppb with conventional controllers), meeting 7nm high-k dielectric purity requirements. The fluorinated gas compatibility also extends seal lifespan to 18 months (vs. 6 months for Viton® seals), cutting maintenance costs by 67%.

Typical application scenarios

7nm Gate Etch (LAM 9000 Series): In leading-edge fabs producing 7nm logic chips, the LAM 810-048219-019 ensures ultra-stable vacuum and proactive maintenance for high-precision etch. The module maintains chamber pressure at 1×10⁻¹⁰ Torr ±2.5%, using dual sensors to cross-verify readings and 200 Hz sampling to capture transient spikes from C₄F₈ desorption. Its AI fault prediction detects abnormal turbomolecular pump vibration (0.2 g vs. 0.05 g baseline), alerting technicians to replace bearings during a scheduled 2-hour maintenance window (avoiding a 10-hour unplanned outage). Syncing with LAM 734-009992-001 (wafer robot), it adjusts pressure during wafer load/unload to avoid vacuum shocks—ensuring etch trench sidewall roughness ≤0.3 nm. The fab reported a 5.2% yield increase and 98.5% tool availability, meeting 7nm HPC chip production targets.

14nm High-Density PE-ALD (LAM 2300 Series): For fabs producing 14nm high-k dielectric films via PE-ALD, the module balances precision and diagnostic intelligence. It maintains chamber pressure at 5×10⁻⁹ Torr ±0.8%, using active temperature control to avoid pressure drifts from ambient temp changes (15°C–50°C). Its leak localization feature identifies a 5×10⁻¹⁴ SCCM leak from a MFC connection, enabling targeted repair without disassembling the entire gas line. The module’s OPC UA integration feeds pressure stability data to LAM Smart Factory Suite, optimizing precursor pulse time and reducing HfCl₄ waste by 25%. The fab achieved 98.9% wafer pass rates, with PE-ALD process stability improved by 40% vs. legacy controllers.

LAM 810-048219-019

Related model recommendations

LAM 810-048219-CAL: Advanced calibration kit for LAM 810-048219-019; Includes NIST-traceable UHV standard (1×10⁻⁴–1×10⁻¹² Torr), vibration calibrator, and AI-driven drift compensation software, extends intervals to 24 months.

LAM 834-028913-025: High-precision MFC paired with LAM 810-048219-019; ±0.2% flow accuracy, syncs gas flow with vacuum pressure to maintain 7nm etch gas ratios.

LAM 796-220745-001: High-integration RF module compatible with LAM 810-048219-019; Adjusts RF power based on vacuum pressure, optimizing plasma stability in 7nm etch.

LAM 716-330122-002: UHV sensor complementary to LAM 810-048219-019; Provides tertiary pressure verification for critical 7nm processes, enhancing diagnostic reliability.

LAM 203-140148-308 (High-Speed Valve): UHV isolation valve synced with LAM 810-048219-019; 15 ms response time, closes if pressure exceeds ±3% of setpoint or leak rate >1×10⁻¹³ SCCM.

LAM 734-009992-001: Precision wafer robot paired with LAM 810-048219-019; The module adjusts pressure during robot load/unload to avoid vacuum shocks, protecting 7nm wafers.

LAM 810-2140-005: Mid-range predecessor of LAM 810-048219-019; 1×10⁻⁴–1×10⁻¹¹ Torr range, suitable for fabs transitioning from 14nm to 7nm.

LAM 856-210020-001: High-purity gas manifold compatible with LAM 810-048219-019; Distributes filtered gas to etch chambers, while the module maintains vacuum to ensure gas-particle consistency.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-048219-019, confirm compatibility with your LAM tool (9000 Series/2300 advanced variants) and update LAM PCS to v8.0+ for diagnostic control. Mount the module via anti-vibration brackets (DIN rail/panel-mount), ensuring ≥20cm clearance from heat sources (e.g., RF generators) and ≥10cm space for cable routing. Connect vacuum lines: Inlet to process chamber (use 1/4” VCR fittings, torqued to 18 in-lbs ±1 in-lb with a calibrated torque wrench); control outputs to dual turbomolecular pumps/throttle valves. For integration: Connect EtherNet/IP (Cat6a) to LAM PCS, RS-485 to auxiliary sensors, and OPC UA to fab MES. Verify the 24 VDC power supply has a dedicated 4A circuit with surge protection; avoid sharing power with high-noise components to prevent sensor interference. Perform initial leak test (target ≤1×10⁻¹⁴ SCCM) and dual-sensor cross-calibration via LAM PCS.

Maintenance suggestions: Perform daily checks via LAM PCS diagnostic dashboard—review pump health metrics (vibration/temp/current), sensor drift, and leak rate. Weekly, clean sensor ports with UHV-compatible isopropyl alcohol (99.999% purity) and inspect valve connections for corrosion (critical for fluorinated gas use). Every 6 months, verify pressure regulation accuracy with a secondary UHV standard; every 12 months, replace Kalrez® seals (even if no leaks) to maintain low outgassing. Use LAM 810-048219-CAL kit every 24 months for full calibration. For 7nm critical lines, keep a spare module on hand—pre-configure vacuum setpoints and