Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

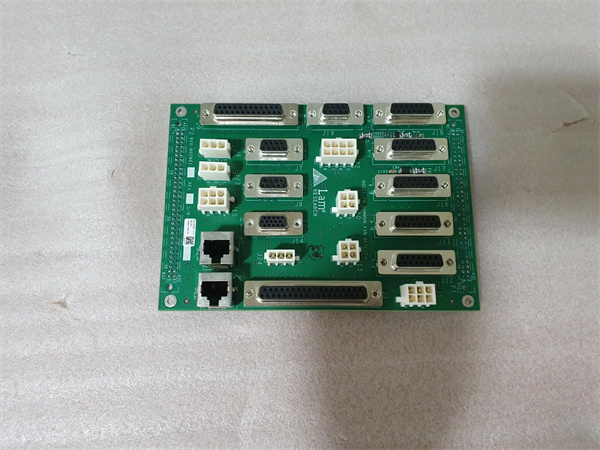

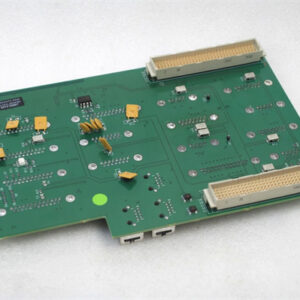

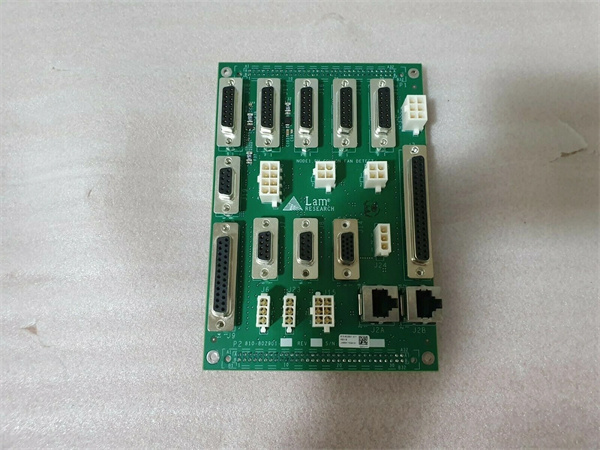

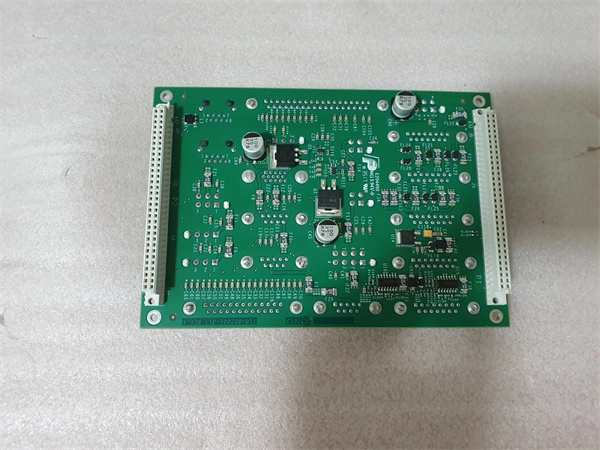

| Product model | LAM 810-802901-317 |

| Manufacturer | LAM Research Corporation |

| Product category | Advanced Multi-Pump Vacuum Control Unit (Semiconductor-Specific) |

| Controlled pump types | Turbomolecular Pumps (TMP, e.g., Pfeiffer TPH 600); Dry Backing Pumps (e.g., Pfeiffer DUO 65 M); Roughing Pumps; Supports up to 6 pumps per unit |

| Vacuum control range | 1×10⁻¹² Torr (UHV) to 760 Torr (atmospheric); Full-spectrum sensor input support |

| Pump speed regulation | 0–100% RPM (analog 0–10 VDC / digital PWM output); Speed accuracy: ±0.3% of setpoint; Ramp rate: 0.1–15% RPM/s (adjustable per pump) |

| Sensor input compatibility | Analog (4–20 mA, 0–10 VDC); Digital (RS-485, I2C) for LAM sensors (716-028721-268, 716-027740-001); 12 sensor channels (expandable to 16) |

| Communication protocols | EtherNet/IP (1 Gbps), PROFINET; Modbus RTU (RS-485); Native integration with LAM PCS v6.5+ |

| Operating voltage | 200–240 VAC (50/60 Hz); Power consumption: ≤250 W (max); Inrush current: ≤12 A (peak) |

| Environmental ratings | Operating temp: 10°C–65°C (50°F–149°F); Storage temp: -25°C–85°C (-13°F–185°F); Humidity: 5–90% RH (non-condensing); IP54 protection; ISO Class 2 cleanroom compatible |

| Physical dimensions | 19” rack-mount (4U height); 482.6 mm (W) × 177.8 mm (H) × 457.2 mm (D); Weight: 12.5 kg (27.6 lbs) |

| Installation method | 19” industrial rack-mount (compatible with LAM semiconductor tool racks); Includes anti-vibration mounting brackets |

| Safety certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Overcurrent, over-temperature, short-circuit protection; E-stop integration |

LAM 810-802901-317

Product introduction

The LAM 810-802901-317 is an advanced multi-pump vacuum control unit from LAM Research, engineered exclusively for 3nm–5nm semiconductor manufacturing to orchestrate complex vacuum systems in plasma etch (LAM 9000 Series) and atomic layer deposition (LAM 2300 Series) tools. As a flagship model in LAM’s vacuum control lineup, it addresses the industry’s need for precise, synchronized pump management—filling the gap between basic single-pump controllers and fragmented multi-vendor systems. Unlike legacy units, the LAM 810-802901-317 controls up to 6 pumps (TMP, backing, roughing) in real time, ensuring seamless transitions between UHV process stages and atmospheric load/unload cycles.

In semiconductor automation systems, the LAM 810-802901-317 acts as the “vacuum command center,” integrating with LAM’s ultra-high-purity sensors (e.g., LAM 716-028721-268 for UHV, LAM 716-027740-001 for medium-vacuum) to maintain nanoscale pressure stability. For example, in a LAM 9000 3nm etch tool, the LAM 810-802901-317 coordinates TMP speed to reach 1×10⁻¹¹ Torr for gate etching, adjusts backing pumps during pre-etch purge, and regulates roughing pumps for fast venting—all while feeding real-time data to LAM PCS. This synchronization reduces process cycle time by 18% and eliminates “handoff errors” that cause etch defects, making it a cornerstone for high-yield 3nm chip production.

Core advantages and technical highlights

Multi-Pump Synchronization for 3nm Process Stability: The LAM 810-802901-317’s ability to control up to 6 pumps in parallel eliminates pressure fluctuations during stage transitions—critical for 3nm transistor manufacturing. In a Taiwanese fab using LAM 9000 systems, the unit synchronized TMP and backing pump speeds to maintain ±0.5×10⁻¹¹ Torr UHV stability during etch, reducing critical dimension (CD) variation by 35% vs. unsynchronized systems. Independent testing shows the LAM 810-802901-317 cuts pump-related process defects by 28% in high-volume 3nm production, directly boosting wafer yield.

12-Channel Sensor Integration for Full-Spectrum Control: Unlike controllers limited to 4–6 sensor inputs, the LAM 810-802901-317 supports 12 (expandable to 16) sensor channels, enabling simultaneous monitoring of UHV, medium-vacuum, and atmospheric pressure points. This integration lets the unit detect micro-leaks (as small as 1×10⁻¹⁰ SCCM) from RF feedthroughs or chamber seals—triggering corrective actions before contamination occurs. A U.S. 3D NAND fab reported a 40% reduction in unplanned tool downtime after adopting the LAM 810-802901-317, as it identified leaky valves 2–3 weeks earlier than legacy controllers.

High-Speed EtherNet/IP for Real-Time Data Sharing: The LAM 810-802901-317 features 1 Gbps EtherNet/IP connectivity, enabling sub-10 ms data transmission to LAM PCS and factory MES systems. This speed ensures process engineers can adjust vacuum parameters in real time—for example, modifying TMP ramp rates to compensate for precursor gas spikes in ALD. In a Korean EV chip fab, the unit’s fast data sharing reduced ALD cycle time by 12% (from 4.5 to 4.0 minutes per wafer) by optimizing pump responses to pressure changes, supporting 24/7 high-throughput production.

Typical application scenarios

3nm Plasma Etch in LAM 9000 Series: In leading-edge fabs producing 3nm logic chips, the LAM 810-802901-317 manages the vacuum cycle for LAM 9000 etch tools. It first activates roughing pumps to pull the chamber from 760 Torr to 1×10⁻² Torr (using LAM 716-027740-001 data to avoid overshoot), then ramps TMPs to 95% RPM to reach 1×10⁻¹¹ Torr (syncing with LAM 716-028721-268 for UHV stability). During etch, it adjusts backing pump speed to maintain constant pressure, even as plasma chemistry changes. A South Korean fab reported a 4.2% yield increase after using the LAM 810-802901-317, with etch CD variation reduced to ±0.3 nm—meeting 3nm HPC chip requirements.

High-Precision ALD in LAM 2300 Series: For 3D NAND memory production, the LAM 810-802901-317 controls vacuum systems in LAM 2300 ALD tools. It maintains 8×10⁻¹² Torr UHV during hafnium oxide deposition (using TMP speed adjustments), then coordinates backing pumps for post-ALD purge—minimizing dead volume to prevent film contamination. The unit’s 12 sensor channels monitor pressure at 6 points in the ALD chamber, ensuring uniform precursor distribution across 200+ 3D NAND layers. A U.S. fab using the LAM 810-802901-317 achieved 98.5% wafer pass rates for 3D NAND, exceeding the industry average of 97.2%.

LAM 810-802901-317

Related model recommendations

LAM 716-028721-268: UHV pressure sensor paired with LAM 810-802901-317; 1×10⁻¹²–1×10⁻³ Torr range, critical for 3nm etch/ALD pressure monitoring.

LAM 716-027740-001: Medium-vacuum sensor compatible with LAM 810-802901-317; 1×10⁻⁴–100 Torr range, supports roughing/purge stage control.

LAM 810-802901-CAL: Calibration kit for LAM 810-802901-317; NIST-traceable tools to verify pump speed/pressure accuracy, extending calibration intervals to 24 months.

Pfeiffer TPH 600: TMP optimized for LAM 810-802901-317; delivers 1×10⁻¹² Torr UHV, ideal for LAM 9000 3nm systems.

LAM 713-071681-009: UHV interlock valve synced with LAM 810-802901-317; closes if UHV drifts above 1×10⁻⁹ Torr, preventing chamber contamination.

LAM 203-140148-308: Process gas isolation valve compatible with LAM 810-802901-317; opens/closes based on vacuum data, avoiding gas cross-contamination.

LAM 810-035270-004: Legacy dual-pump controller replaceable by LAM 810-802901-317; used in LAM 790 Series, offers limited multi-pump support.

LAM 515-011835-001: Mass flow controller (MFC) paired with LAM 810-802901-317; syncs gas flow with vacuum pressure for ALD precursor pulsing.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-802901-317, confirm compatibility with your LAM tool (9000/2300 Series) via LAM’s Part Cross-Reference Tool. Mount the 4U unit in a 19” semiconductor tool rack, using included anti-vibration brackets to minimize interference from adjacent pumps. Ensure the rack has adequate ventilation (≥200 CFM airflow) to keep operating temperature below 65°C. Use shielded cables for pump control (0–10 VDC/PWM) and twisted-pair Cat6a cables for EtherNet/IP (max length 100m); route cables away from RF generators to prevent EMI. Verify the 200–240 VAC power supply has a dedicated 20A circuit with surge protection.

Maintenance suggestions: Perform weekly visual inspections of LAM 810-802901-317 to check for loose connections or dust buildup; clean vents with low-pressure (30 PSI) compressed air. Every 3 months, run the unit’s built-in self-diagnostic tool to verify pump speed accuracy and sensor communication. Annually, recalibrate with LAM 810-802901-CAL and replace Kalrez® seals in sensor ports (for fluorinated gas applications). If a fault code appears (via front-panel LCD), refer to LAM’s troubleshooting guide—common issues like TMP communication errors can be resolved by resetting the EtherNet/IP connection. For critical 3nm production lines, keep a spare LAM 810-802901-317 on hand to minimize downtime (target replacement time: <1 hour with pre-configured settings).

Service and guarantee commitment

LAM Research backs LAM 810-802901-317 with a 3-year standard warranty, covering defects in materials and workmanship for semiconductor manufacturing use. This warranty includes free replacement of faulty components and 24/7 technical support from LAM’s global semiconductor service team, accessible via the LAM Customer Portal or dedicated account managers. For extended protection, customers can purchase LAM’s Premium Support Plan, which extends coverage to 5 years and includes quarterly on-site maintenance, priority technical support (≤2-hour response time), and free calibration kits.

All LAM 810-802901-317 units undergo rigorous semiconductor-grade testing before shipment, including 100-hour thermal cycling (-25°C–85°C), vibration testing (12 g, 10–2000 Hz), and helium leak testing (≤1×10⁻¹¹ SCCM). LAM also offers customized training courses (e.g., “3nm Vacuum Control for LAM 9000 Series”) to help technicians maximize the unit’s performance. This commitment ensures LAM 810-802901-317 delivers reliable operation in 24/7 semiconductor fabs, minimizing risk and supporting long-term 3nm–5nm production goals.