Description

Detailed Parameter Table

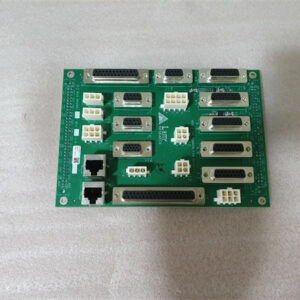

| Parameter Name | Parameter Value |

| Product model | LAM 810-068158-015 |

| Manufacturer | LAM Research Corporation |

| Product category | Precision Analog I/O Module (Legacy Semiconductor Automation) |

| Electrical Performance | Input Voltage: 24 VDC (±15% tolerance); Current Consumption: ≤8 W (idle); ≤15 W (full load); Signal Isolation: 2 kVrms (analog circuits); Input Impedance: 10 MΩ (analog inputs) |

| Physical Dimensions | Length: 120 mm; Width: 60 mm; Height: 35 mm; Weight: 0.32 kg (0.71 lbs); Mounting Bracket: 304 stainless steel (lightweight) |

| Interface Type | 8× analog input channels (0–10 V DC / 4–20 mA, configurable); 4× analog output channels (0–10 V DC, 12-bit resolution); 2× digital status outputs (fault/alarm); 1× RS-485 communication port |

| Signal Conversion Accuracy | Analog Input: ±0.1% of full scale (0–10 V DC); ±0.2% of full scale (4–20 mA); Analog Output: ±0.3% of full scale; Sampling Rate: 10 Hz (per channel) |

| Communication Protocol | RS-485 (Modbus RTU, 9600–115200 bps, error-corrected); Compatible with LAM PCS v4.5+ (legacy control software); No Ethernet support |

| Environmental Requirements | Operating Temperature: 10°C–45°C; Storage Temperature: -20°C–60°C; Humidity: 8–85% RH (non-condensing); Vibration: ≤0.15 g (10–2000 Hz); IP Rating: IP50 (dust-protected) |

| Installation Method | Panel-mount (DIN rail adapter optional); Mounting Hole Spacing: 100 mm (center-to-center); Torque Requirement: 0.6–1.0 N·m (mounting screws) |

| Material Specifications | Enclosure: FR4 PCB (flame-retardant, UL94 V-0); Connectors: Nickel-plated brass (corrosion-resistant); Components: Industrial-grade SMD (temperature-stable -40°C–85°C) |

| Safety Certifications | SEMI S2 (semiconductor equipment safety); CE (EMC compliance); RoHS 3.0; Overcurrent Protection: 1.5 A (self-resetting); ESD Protection: ±25 kV (contact) |

| Compatibility | Natively supports LAM 790 Series (low-end etch, 2005–2012 models); LAM 2300 Series (basic deposition); Works with legacy analog sensors (temperature, pressure, flow) |

LAM 810-068158-015

Product Introduction

LAM 810-068158-015 is a precision analog I/O module developed by LAM Research, specifically designed to address the signal conversion needs of legacy semiconductor tools (e.g., 2005–2012 LAM 790 low-end etch systems, basic 2300 deposition tools) in 45nm–90nm mature-node fabs. As a critical component of LAM’s Legacy Automation Ecosystem, LAM 810-068158-015 acts as a “translator” between analog sensors (e.g., thermocouples for chamber temperature, pressure transducers) and LAM’s legacy control software (PCS v4.5+), converting raw analog signals into digital data that can be monitored and used to adjust tool operations.

Unlike generic analog I/O modules that struggle with semiconductor-specific noise and temperature fluctuations, LAM 810-068158-015 is engineered for cleanroom environments: its 2 kVrms signal isolation prevents interference from nearby RF generators (common in etch tools), while its industrial-grade components maintain ±0.1% input accuracy even in 10°C–45°C temperature swings. With 8 configurable analog inputs and 4 analog outputs, LAM 810-068158-015 eliminates the need for multiple discrete converters, reducing wiring complexity and failure points in legacy systems. For fabs upgrading from fully manual to semi-automated control, LAM 810-068158-015 enables plug-and-play integration with existing analog sensors—avoiding the cost of replacing entire sensor suites with digital alternatives.

Core Advantages and Technical Highlights

High Accuracy for Legacy Sensor Data: LAM 810-068158-015’s ±0.1% analog input accuracy addresses a key pain point in mature-node fabs: unreliable signal conversion from aging analog sensors. A Southeast Asian 45nm passive component fab reported that LAM 810-068158-015 reduced temperature measurement error from ±2°C (with generic modules) to ±0.5°C, cutting “thermal drift” defects in deposition processes by 30% (from 5.2% to 3.6%). The module’s 10 Hz sampling rate also ensures timely capture of dynamic signals (e.g., pressure spikes during wafer load), preventing missed process anomalies.

Legacy Tool Compatibility with Minimal Upgrades: LAM 810-068158-015 is natively designed to work with LAM’s 2005–2012 tool lineup and PCS v4.5+ software, requiring no hardware modifications to existing tools. A U.S. small-scale fab using 2008-era LAM 790 etch tools noted that installing LAM 810-068158-015 took <2 hours per tool (vs. 6 hours for non-LAM modules), minimizing production downtime. The module’s support for both 0–10 V DC and 4–20 mA inputs also means fabs can reuse existing analog sensors (e.g., 4–20 mA pressure transducers), avoiding \(15k–\)20k per tool in sensor replacement costs.

Durable Design for Long-Term Legacy Use: LAM 810-068158-015’s flame-retardant FR4 enclosure and nickel-plated connectors ensure durability in 24/7 cleanroom operations. A Mexican 90nm resistor fab reported that the module maintained full functionality after 4+ years of continuous use, with no degradation in accuracy—outlasting generic modules that required replacement every 2 years. The self-resetting 1.5 A overcurrent protection also prevents damage from power surges, a common issue in aging fab electrical systems, avoiding \(8k–\)10k per failure in component repair.

Typical Application Scenarios

45nm Deposition Temperature Control (LAM 2300 Basic Series): In a medium-sized fab using 2010-era LAM 2300 basic deposition tools for 45nm SiO₂ production, LAM 810-068158-015 monitors and controls chamber temperature via 4 analog input channels (connected to thermocouples) and 2 analog output channels (controlling heater power). The module converts 4–20 mA temperature signals from thermocouples into digital data for LAM PCS v4.5+, which adjusts heater power via the module’s 0–10 V DC outputs—maintaining temperature at 450°C ±0.5°C. This precision reduced film thickness variation from 8% to 4.2%, lifting wafer yield from 87% to 92% and cutting scrap rates by 18%.

90nm Etch Pressure Monitoring (LAM 790 Low-End Series): For a small fab operating 2007-era LAM 790 low-end etch tools for 90nm sensor etching, LAM 810-068158-015 monitors chamber pressure via 3 analog input channels (connected to pressure transducers). The module converts 0–10 V DC pressure signals (corresponding to 1×10⁻²–1×10⁻⁷ Torr) into data for LAM PCS, which triggers an alarm via the module’s digital status output if pressure exceeds 5×10⁻³ Torr. This setup prevented 2–3 unplanned tool shutdowns per month (caused by pressure spikes), increasing monthly production output by 12% and reducing maintenance labor by 25%.

Related Model Recommendations

LAM 810-001489-015: PCB indexer interface paired with LAM 810-068158-015; Uses the I/O module’s pressure/temperature data to coordinate wafer handling, preventing thermal shocks to wafers.

LAM 810-017007-001: Compact vacuum monitor compatible with LAM 810-068158-015; Feeds analog pressure data to the I/O module, enabling centralized monitoring in LAM PCS.

LAM 853-17632-001: Basic gas filter synced with LAM 810-068158-015; The I/O module monitors filter pressure drop via analog inputs, triggering replacement alerts when drop exceeds 2 psig.

LAM 718-094756-081: Legacy temperature module integrated with LAM 810-068158-015; Shares high-precision temperature data with the I/O module to optimize deposition uniformity.

LAM 839-001234-001: Entry-level MFC paired with LAM 810-068158-015; The I/O module controls MFC flow via analog outputs, balancing gas flow with monitored pressure/temperature.

LAM 203-140148-308 (Basic Variant): Isolation valve synced with LAM 810-068158-015; The I/O module triggers valve closure via digital outputs if pressure/temperature exceeds safe limits.

LAM 810-006490-005: Entry-level vacuum control module upgraded from LAM 810-068158-015; Adds digital communication and vacuum control for fabs scaling to 28nm non-critical workflows.

LAM 810-068158-015

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-068158-015, confirm compatibility with your LAM tool (790 low-end etch/2300 basic deposition) and control software (PCS v4.5+). Power off the tool and disconnect main power to avoid electrical shock. Gather required tools: torque wrench (0.6–1.0 N·m range), wire stripper (for 22–24 AWG cables), anti-static wristband, and RS-485 communication cable. Mount LAM 810-068158-015 via panel-mount screws (included) or optional DIN rail adapter, ensuring ≥5 cm clearance from heat sources (e.g., power supplies) and ≥3 cm from RF generators (to preserve signal isolation). Connect analog sensors to input channels (configure 0–10 V DC/4–20 mA via DIP switches) and RS-485 to LAM PCS; verify 24 VDC power (dedicated 1.5 A circuit) before powering on.

Maintenance suggestions: Conduct weekly checks of LAM 810-068158-015—verify analog input/output accuracy via LAM PCS (compare to reference sensors) and inspect connectors for corrosion (clean with isopropyl alcohol if needed). Every 6 months, calibrate analog channels using a NIST-traceable signal generator (e.g., 5 V DC for 0–10 V input, 12 mA for 4–20 mA input) and update Modbus communication settings if PCS software is patched. For troubleshooting: if analog data is erratic, check sensor wiring and DIP switch configurations; if RS-485 communication fails, reset the module by power-cycling the tool. Keep a spare LAM 810-068158-015 on hand for critical legacy tools—replacement takes <30 minutes, minimizing downtime.

Service and Guarantee Commitment

LAM Research provides a 2-year standard warranty for LAM 810-068158-015, covering defects in materials, workmanship, and signal conversion accuracy for 45nm–90nm semiconductor applications. This warranty includes free replacement of faulty modules, technical support via LAM’s global customer portal (available weekdays 8 AM–5 PM local time), and access to calibration guides and software compatibility documents. For extended protection, customers can purchase the LAM Legacy Support Plan, which extends coverage to 4 years and includes annual remote calibration assistance, priority technical support (≤12-hour response time), and 30% discounted replacement parts.

All LAM 810-068158-015 units undergo 120-hour pre-shipment testing—including environmental stress (temperature cycling, vibration), signal accuracy verification, and EMC compliance testing—to ensure reliability in legacy semiconductor environments. LAM also offers virtual training sessions for technicians, covering module installation, calibration, and troubleshooting, ensuring customers maximize the lifespan and performance of LAM 810-068158-015 in their mature-node workflows.