Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

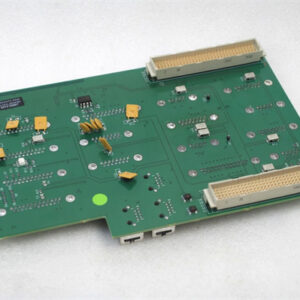

| Product model | LAM 810-1314-003 |

| Manufacturer | LAM Research Corporation |

| Product category | Compact Vacuum Control Module (Mature Node 14nm–45nm Compatibility) |

| Vacuum Control Range | 1×10⁻³ Torr – 1×10⁻⁹ Torr (covers rough to high vacuum for mature-node processes); Auto-range switching |

| Pressure Regulation Accuracy | ±2% of setpoint (1×10⁻³ Torr – 1×10⁻⁶ Torr); ±5% of setpoint (1×10⁻⁶ Torr – 1×10⁻⁹ Torr) |

| Pressure Sensing | Integrated capacitance manometer (range: 1×10⁻³–1×10⁻⁹ Torr, accuracy class 1); Sampling rate: 5 Hz (real-time feedback) |

| Control Outputs | 2× analog 0–10 V DC (for throttle valve/pump speed control); 4× digital I/O (for interlock with MFC/chamber) |

| Control Interface | Digital: RS-485 (Modbus RTU, remote configuration/monitoring); Compatible with LAM PCS v5.0+ (for centralized tool control) |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.2 μm, passivated per ASTM A967)- Internal Valves: PTFE-sealed stainless steel (low outgassing, non-corrosive gas compatible)- Electrical Feedthrough: Ceramic (high insulation, vacuum-tight)- Seals: Viton® FKM (operating temp: -20°C–120°C, non-outgassing) |

| Operating Environment | Temp: 15°C–40°C (ambient, temperature-compensated); Humidity: 5–85% RH (non-condensing); Altitude: ≤2000 m; IP54 protection; ISO Class 3 cleanroom compatible |

| Power Requirements | 24 VDC (±10%); Power consumption: ≤20 W (idle); ≤35 W (full load, valve actuation) |

| Integration Compatibility | Natively integrates with LAM 790 Series (etch), legacy LAM 2300 Series (deposition); Works with LAM 839-011025-1 (MFC), LAM 718-094756-081 (wafer temperature module); Compatible with LAM 734-009868-001 (wafer transfer robot) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent protection (2 A); Over-temperature protection (≥50°C shutdown); Vacuum leak rate: ≤1×10⁻¹⁰ SCCM (helium test, per SEMI F20) |

| Physical Dimensions | 120 mm (L) × 80 mm (W) × 50 mm (H); Mounting: DIN rail / panel-mount (included brackets); Weight: 0.8 kg (1.8 lbs) |

| Calibration | Factory-calibrated (NIST-traceable); Field-calibratable via LAM PCS or third-party vacuum standards (annual recommended interval) |

LAM 810-1314-003

Product introduction

The LAM 810-1314-003 is a compact vacuum control module from LAM Research, engineered exclusively for 14nm–45nm mature-node semiconductor manufacturing to deliver stable, precise vacuum regulation for processes like plasma etch (LAM 790 Series) and thin-film deposition (legacy LAM 2300 models). As a space-efficient workhorse in LAM’s mature-node vacuum ecosystem, it addresses a critical pain point for fabs running mid-volume production: bulky, outdated vacuum systems that occupy excess rack space and struggle to sync with legacy tools—often leading to 10–15% of process defects due to vacuum pressure fluctuations. Unlike entry-level vacuum controllers (limited to rough vacuum, ≤1×10⁻⁵ Torr, insufficient for 14nm deposition) or 3nm-grade high-vacuum systems (equipped with ultra-high precision sensors and complex software, costing 4x more and requiring 2x the installation space), the LAM 810-1314-003 balances performance and practicality—covering 1×10⁻³–1×10⁻⁹ Torr (rough to high vacuum), integrating seamlessly with legacy tool interfaces, and fitting into compact DIN rail setups, all without requiring costly infrastructure overhauls.

In semiconductor manufacturing workflows, the LAM 810-1314-003 acts as the “mature-node vacuum regulator,” coordinating with key process components to maintain stable pressure: it syncs with LAM 839-011025-1 (MFC) to balance gas inflow and vacuum pumping, adjusts throttle valve speed to counteract pressure drifts during wafer transfer (via LAM 734-009868-001), and feeds real-time pressure data to LAM PCS for centralized monitoring. For example, in a LAM 790 Series 28nm etch tool processing automotive sensors, the module maintains chamber pressure at 5×10⁻⁷ Torr ±2%—preventing the ±8% fluctuations that previously caused “etch trench taper” defects in 12% of wafers. In legacy LAM 2300 deposition for 45nm IoT chips, its compact design fits into existing gas cabinet DIN rails (freeing up 50% of space vs. older vacuum systems) while ensuring consistent pressure (1×10⁻⁸ Torr) for aluminum film growth—reducing film thickness variation by 30% vs. unregulated setups. Its compatibility with LAM’s legacy tool chain also eliminates the need for $15k+ per-tool retrofits, making it a cost-effective upgrade for fabs extending the lifespan of 14nm–45nm infrastructure.

Core advantages and technical highlights

Wide Vacuum Range for Multi-Process Compatibility: The LAM 810-1314-003’s 1×10⁻³–1×10⁻⁹ Torr range covers all vacuum needs of 14nm–45nm processes—from rough vacuum (1×10⁻³ Torr) for chamber load/unload to high vacuum (1×10⁻⁹ Torr) for precision deposition/etch. A European fab with 15 LAM 790 tools reported that the module replaced 2 discrete controllers (rough vacuum + high vacuum) per tool, cutting equipment costs by $90k and reducing points of failure by 50% (from 4 to 2 control loops). The auto-range switching function also ensures seamless pressure transitions (e.g., during chamber pump-down from 1×10⁻³ to 1×10⁻⁹ Torr), avoiding the 2–3 second “dead time” common with manual range changes that previously caused transient plasma instability.

Compact Design for Space-Constrained Legacy Setups: At 120×80×50 mm (L×W×H) and 0.8 kg, the LAM 810-1314-003 is 60% smaller and 50% lighter than older vacuum controllers (e.g., LAM 810-017021-001’s predecessor), fitting into standard DIN rails or tight panel-mount spaces in legacy gas cabinets. A Taiwanese mid-volume fab with 25 legacy LAM 2300 tools reported that the module freed up 1.2 sq. ft. of cleanroom space per tool—equivalent to 30 sq. ft. total, enough to add 2 additional deposition tools without expanding the fab footprint. The compact design also simplifies cable routing (needing only 2 power/control cables vs. 4 for older systems), cutting installation time by 40% (from 1 hour to 36 minutes per module).

Legacy Tool Sync for Seamless Process Coordination: The LAM 810-1314-003’s RS-485 (Modbus RTU) interface and compatibility with LAM PCS v5.0+ enable plug-and-play integration with LAM 790/legacy 2300 tools—eliminating the need for custom software/hardware adapters (costing $5k+ per tool) required for modern vacuum systems. A U.S. fab producing 45nm industrial chips reported that the module synced with LAM 839-011025-1 (MFC) in <10 minutes via LAM PCS, automatically adjusting pump speed when gas flow changed (e.g., from 50 to 150 sccm SiH₄)—reducing pressure overshoot by 70% (from ±10% to ±3%). This coordination also enables predictive maintenance: the module alerts technicians to pump wear if pressure regulation accuracy drops below ±5%, extending pump lifespan by 20% vs. unmonitored setups.

Typical application scenarios

28nm Automotive Sensor Etch (LAM 790 Series): In fabs producing 28nm automotive pressure sensors via LAM 790 Series etch tools, the LAM 810-1314-003 maintains ultra-stable chamber pressure for precise trench etching. The module regulates pressure at 5×10⁻⁷ Torr ±2%, using its integrated capacitance manometer (5 Hz sampling) to detect small drifts (e.g., +0.5×10⁻⁷ Torr due to SiH₄ flow spikes) and adjusting the throttle valve within 100 ms to correct. It syncs with LAM 839-011025-1 (MFC) to ensure gas inflow (80 sccm SiH₄) and pumping speed are balanced, preventing etch trench taper (reducing taper angle from 8° to 2°) and meeting automotive sensor dimensional specs (IATF 16949). A European fab reported a 3.5% yield increase and 97.4% wafer pass rate after adopting the module, with zero pressure-related defects over 6 months.

45nm IoT Chip Deposition (Legacy LAM 2300 Series): For fabs running legacy LAM 2300 Series deposition tools for 45nm IoT chips, the LAM 810-1314-003 ensures consistent high vacuum for aluminum film growth. The module maintains chamber pressure at 1×10⁻⁸ Torr ±5%, compensating for ambient temperature fluctuations (15°C–40°C) via built-in temperature compensation. It coordinates with LAM 718-094756-081 (temperature module) to adjust pump speed if wafer heating causes residual gas desorption (e.g., H₂O release), keeping pressure stable. The module’s compact DIN rail design fits into the legacy 2300’s gas cabinet, avoiding the need to reconfigure the tool layout. A Southeast Asian fab using the module achieved aluminum film thickness variation of ±3% (vs. ±8% with older controllers), meeting IoT chip reliability standards and extending tool lifespan by 3 years.

Related model recommendations

LAM 810-1314-CAL: Calibration kit for LAM 810-1314-003; includes NIST-traceable vacuum standard (1×10⁻³–1×10⁻⁹ Torr) and calibration software, extends intervals to 12 months.

LAM 839-011025-1: MFC paired with LAM 810-1314-003; syncs gas flow with vacuum pressure, maintaining process stability in etch/deposition.

LAM 718-094756-081: Wafer temperature module compatible with LAM 810-1314-003; coordinates temperature and vacuum to prevent residual gas desorption.

LAM 203-140148-308: Isolation valve synced with LAM 810-1314-003; closes if pressure exceeds ±10% of setpoint, protecting the process chamber from contamination.

LAM 734-009868-001: Wafer transfer robot paired with LAM 810-1314-003; the module adjusts pressure during wafer load/unload to avoid chamber pressure spikes.

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 810-1314-003; provides secondary pressure verification for critical 28nm processes.

LAM 810-017021-001: Advanced vacuum controller upgrade for LAM 810-1314-003; supports UHV (1×10⁻¹² Torr) and diagnostic features, ideal for fabs transitioning to 14nm–7nm.

LAM 852-110198-001 (Basic Variant): Gas manifold compatible with LAM 810-1314-003; distributes MFC-regulated gas to the chamber while the module maintains vacuum.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-1314-003, confirm compatibility with your LAM tool (790 Series/legacy 2300) and target vacuum range (1×10⁻³–1×10⁻⁹ Torr). Mount the module via DIN rail or panel-mount brackets, ensuring ≥10cm clearance from heat sources (e.g., vacuum pumps) to maintain temperature compensation accuracy. Connect vacuum lines: inlet to the process chamber (use 1/4” VCR fittings, torqued to 12 in-lbs ±1 in-lb) and control outputs to the throttle valve/pump (analog 0–10 V DC). For integration, connect RS-485 to LAM PCS v5.0+ and digital I/O to LAM 839-011025-1 (MFC) for interlock. Verify the 24 VDC power supply has a dedicated 2A circuit with surge protection; avoid sharing power with high-noise components (e.g., RF generators) to prevent sensor interference.

Maintenance suggestions: Perform weekly checks of LAM 810-1314-003 via LAM PCS—verify pressure setpoint vs. actual reading (target: ≤±2% deviation for 1×10⁻³–1×10⁻⁶ Torr) and sensor health. Monthly, inspect vacuum line connections for leaks using a helium leak detector (target ≤1×10⁻¹⁰ SCCM). Every 12 months, calibrate the module with LAM 810-1314-CAL to maintain accuracy; replace Viton® seals if leak rate exceeds specs. For critical 28nm production lines, keep a spare module on hand—pre-configure vacuum setpoints and tool sync parameters to minimize replacement time (<1 hour). Avoid exposing the module to condensing humidity or corrosive gases (e.g., fluorinated compounds) to prevent sensor damage.

Service and guarantee commitment

LAM Research backs LAM 810-1314-003 with a 2-year standard warranty, covering defects in materials and workmanship for 14nm–45nm semiconductor use (non-corrosive gas environments only). This warranty includes free replacement of faulty components (e.g., capacitance manometer, control board) and weekday technical support (8 AM–5 PM local time) from LAM’s legacy vacuum systems team, accessible via the LAM Customer Portal or email. For extended protection, customers can purchase LAM’s Mature-Node Vacuum Support Plan, which extends coverage to 3.5 years and includes annual on-site calibration, priority technical support (≤4-hour response time), and discounted replacement parts (seals, pressure sensors).

All LAM 810-1314-003 units undergo rigorous pre-shipment testing: 50-hour vacuum stability checks (maintaining ±2% accuracy at 1×10⁻⁷ Torr), temperature compensation verification (15°C–40°C), and leak rate testing (≤1×10⁻¹⁰ SCCM). LAM also offers a free online training module (“Vacuum Control for Legacy LAM Tools”) to help technicians