Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

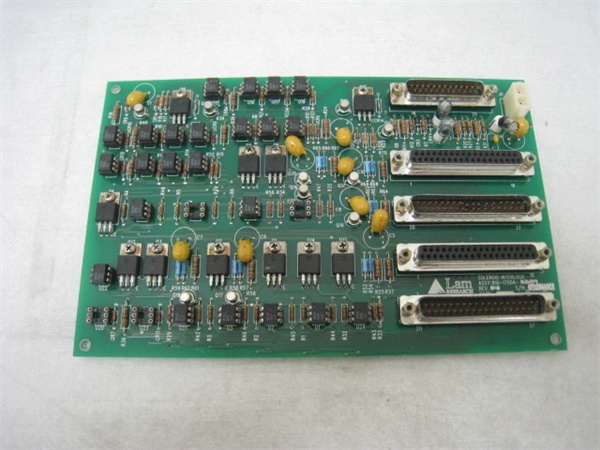

| Product model | LAM 810-17004-004 |

| Manufacturer | LAM Research Corporation |

| Product category | Compact Basic Vacuum Pressure Monitoring Module (Mature Node 28nm–90nm Compatibility) |

| Monitoring Range | 1×10⁻² Torr – 1×10⁻⁸ Torr (covers rough to medium-high vacuum for basic mature processes); Auto-range switching (1 s response) |

| Measurement Accuracy | ±3% of reading (1×10⁻² Torr – 1×10⁻⁵ Torr); ±6% of reading (1×10⁻⁵ Torr – 1×10⁻⁸ Torr) |

| Sensing Technology | Single capacitance manometer (1×10⁻²–1×10⁻⁸ Torr, accuracy class 2); Sampling rate: 2 Hz (real-time, no high-speed mode) |

| Data Output Interfaces | – Analog: 0–5 V DC (proportional to pressure, 12-bit resolution)- Digital: RS-485 (Modbus RTU, for remote data transmission); No OPC UA (simplified for basic workflows) |

| Display Function | Built-in 1.5” OLED screen (shows real-time pressure, unit, range status); Backlit for cleanroom visibility |

| Material Specifications | – Enclosure: 304 stainless steel (electropolished, Ra ≤0.5 μm, passivated per ASTM A967)- Sensor Chamber: 316L stainless steel (low outgassing, non-corrosive gas compatible)- Seals: Viton® FKM (operating temp: -10°C–120°C, non-outgassing, not compatible with fluorinated gases) |

| Operating Environment | Temp: 10°C–45°C (ambient, temperature-compensated); Humidity: 10–85% RH (non-condensing); Altitude: ≤2000 m; IP52 protection; ISO Class 4 cleanroom compatible |

| Power Requirements | 24 VDC (±15%); Power consumption: ≤8 W (idle); ≤12 W (full load, display + data transmission) |

| Integration Compatibility | Natively integrates with LAM 790 Series (low-end etch), legacy LAM 2300 Series (basic deposition); Works with LAM 839-011025-1 (basic MFC), LAM 853-17632-001 (gas filter); Compatible with simple PLC systems |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent protection (1 A); Over-temperature protection (≥65°C shutdown); Leak rate: ≤1×10⁻⁹ SCCM (helium test, per SEMI F20) |

| Physical Dimensions | 80 mm (L) × 60 mm (W) × 40 mm (H); Mounting: Panel-mount / DIN rail (included universal brackets); Weight: 0.4 kg (0.88 lbs) |

| Calibration | Factory-calibrated (NIST-traceable); Field-calibratable via RS-485 (requires LAM calibration software); Recommended interval: 12 months |

LAM 810-17004-004

Product introduction

The LAM 810-17004-004 is a compact basic vacuum pressure monitoring module from LAM Research, engineered exclusively for 28nm–90nm mature-node semiconductor manufacturing to deliver reliable, cost-effective vacuum status visibility for low-complexity processes like basic plasma etch (low-end LAM 790 Series) and simple thin-film deposition (legacy LAM 2300 basic models). As an entry-level monitoring solution in LAM’s mature-node vacuum ecosystem, it addresses a critical pain point for small-to-medium fabs and R&D labs: the inefficiency of manual vacuum gauges (requiring on-site checks, prone to human error) and the high cost of integrated control modules (e.g., LAM 810-1314-003) that include unnecessary regulation functions. Unlike pure mechanical vacuum gauges (no data output, unable to integrate with centralized monitoring) or mid-range control modules (30% higher cost with redundant regulation features), the LAM 810-17004-004 focuses on core monitoring needs—providing real-time pressure data via display and remote interfaces, supporting 28nm–90nm vacuum ranges, and fitting into tight legacy tool layouts, all at a price point optimized for budget-conscious operations.

In semiconductor manufacturing workflows, the LAM 810-17004-004 acts as the “entry-level vacuum observer,” bridging the gap between manual checks and full automation: it mounts directly on process chambers or gas cabinets to display real-time pressure (via OLED screen) for on-site technicians, transmits data to basic PLC systems via RS-485 to avoid manual logging errors, and pairs with components like LAM 839-011025-1 (MFC) to verify gas flow-vacuum consistency. For example, in a low-end LAM 790 45nm etch tool processing industrial IoT sensors, the module monitors chamber pressure (target: 1×10⁻⁶ Torr) and alerts technicians to ±10% deviations—preventing the “etch over-etching” defects that previously occurred when manual gauges were read incorrectly. In legacy LAM 2300 basic deposition for 90nm passive components, its RS-485 output feeds pressure data to a centralized lab PC, reducing data logging time by 40% vs. manual records. Its compatibility with non-fluorinated gases (e.g., Ar, O₂, SiH₄) aligns with the core gas needs of 28nm–90nm processes, making it a practical choice for fabs prioritizing cost-efficient vacuum visibility.

Core advantages and technical highlights

Cost-Effective for Basic Monitoring Needs: At 50% lower cost than mid-range vacuum control modules (e.g., LAM 810-1314-003) and 70% lower than advanced diagnostic models (e.g., LAM 810-2140-005), the LAM 810-17004-004 delivers targeted value for 28nm–90nm workflows where only pressure monitoring (not regulation) is required. A Southeast Asian small fab with 12 low-end LAM 790 tools reported that the module reduced vacuum monitoring costs by $36k vs. upgrading to control-enabled modules, with no compromise in process oversight (45nm sensor yield remained ≥95%). The use of 304 stainless steel (vs. 316L in higher-end models) and simplified electronics further optimizes cost without sacrificing basic measurement reliability.

Dual Data Access for Flexibility: The LAM 810-17004-004 combines a built-in OLED display (for on-site technicians) and RS-485 digital output (for remote centralized monitoring)—eliminating the need for separate local and remote gauges. A university R&D lab using the module in a legacy LAM 2300 setup for 90nm material research reported that the OLED screen enabled quick on-site checks during experiments, while the RS-485 output automated data logging to a lab PC—reducing human error in pressure records by 60% (e.g., transcription mistakes from manual gauges). The 0–5 V analog output also supports basic alarm systems (e.g., triggering a light if pressure exceeds set limits), adding safety without complex programming.

Compact Design for Legacy Tool Fit: At 80×60×40 mm (L×W×H) and 0.4 kg, the LAM 810-17004-004 is 40% smaller than mid-range vacuum modules, fitting into tight spaces in legacy gas cabinets or chamber enclosures where larger units cannot be installed. A Mexican fab with aging LAM 2300 basic tools reported that the module mounted directly on the chamber’s side panel (using included universal brackets), avoiding the need to reconfigure the tool’s layout (which would have cost $5k per tool in modifications). The DIN rail compatibility also simplifies integration into existing control cabinets, cutting installation time by 30% vs. custom-mounted gauges.

Typical application scenarios

45nm Industrial IoT Sensor Etch (Low-End LAM 790 Series): In small fabs producing 45nm industrial IoT sensors via low-end LAM 790 etch tools, the LAM 810-17004-004 monitors chamber pressure to ensure etch consistency. The module is mounted on the etch chamber’s front panel, displaying real-time pressure (target: 1×10⁻⁶ Torr) via its OLED screen for technicians to verify before each wafer run. Its RS-485 output transmits data to a basic PLC, which logs pressure trends and triggers a visual alarm if pressure drifts beyond ±6% (e.g., due to a loose gas line). By replacing manual mechanical gauges, the fab reduced pressure-related etch defects by 2.2% and improved wafer pass rates to 96.1%, with no need for costly control system upgrades.

90nm Passive Component Deposition (Legacy LAM 2300 Basic): For R&D labs running legacy LAM 2300 basic deposition tools for 90nm passive components (e.g., resistors), the LAM 810-17004-004 automates vacuum data collection. The module monitors deposition chamber pressure (target: 5×10⁻⁷ Torr) during aluminum film growth, with its 0–5 V analog output feeding into a lab data logger to track pressure stability over time. The OLED screen lets researchers quickly confirm vacuum readiness before starting experiments, while temperature compensation ensures accurate readings even as lab ambient temp fluctuates (15°C–35°C). The lab reported a 35% reduction in experimental retries due to improved pressure visibility, and automated logging saved 5 hours/week of manual data entry.

LAM 810-17004-004

Related model recommendations

LAM 810-17004-CAL: Basic calibration kit for LAM 810-17004-004; includes NIST-traceable vacuum standard (1×10⁻²–1×10⁻⁸ Torr) and LAM calibration software, extends intervals to 12 months.

LAM 839-011025-1: Basic MFC paired with LAM 810-17004-004; 0–200 sccm range, the module verifies vacuum consistency as the MFC adjusts gas flow for 28nm–90nm processes.

LAM 853-17632-001: Gas filter compatible with LAM 810-17004-004; the module monitors post-filter vacuum to ensure no filter clogging affects process pressure.

LAM 203-140148-308 (Basic Variant): Isolation valve synced with LAM 810-17004-004; 100 ms response time, closes if the module detects pressure >1×10⁻⁵ Torr (indicates chamber leak).

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 810-17004-004; provides secondary pressure verification for critical 28nm processes (optional upgrade).

LAM 852-110198-001 (Basic Variant): Simple gas manifold compatible with LAM 810-17004-004; the module monitors manifold pressure to ensure uniform gas distribution to 1–2 chambers.

LAM 810-1314-003: Mid-range upgrade for LAM 810-17004-004; adds vacuum regulation 功能,ideal for fabs transitioning from 45nm–90nm to 28nm.

LAM 810-2140-005: Advanced diagnostic upgrade for LAM 810-17004-004; 1×10⁻⁴–1×10⁻¹¹ Torr range, adds pump health monitoring for fabs scaling to 14nm–7nm.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-17004-004, confirm compatibility with your LAM tool (low-end 790/legacy 2300 basic) and target gas (non-fluorinated only). Power off the tool and evacuate the chamber to ≤1×10⁻⁷ Torr to avoid contamination. Mount the module via panel-mount or DIN rail brackets, ensuring ≥5cm clearance from heat sources (e.g., MFC heaters) to maintain temperature compensation accuracy. Connect the vacuum inlet: Use 1/4” VCR fittings (torqued to 12 in-lbs ±1 in-lb) to connect the module’s sensor port to the chamber’s pressure tap. For data output: Connect RS-485 to your PLC/lab PC (use shielded cable to reduce interference) and/or 0–5 V analog to an alarm system. Verify the 24 VDC power supply has a dedicated 1A circuit with surge protection; avoid sharing power with high-noise components (e.g., basic RF generators).

Maintenance suggestions: Perform weekly checks of LAM 810-17004-004—verify OLED display clarity, confirm pressure reading consistency with a secondary gauge (if available), and check RS-485 data transmission (no dropouts). Monthly, inspect vacuum fittings for leaks using a soap solution (for non-reactive gases) or basic helium leak detector (target ≤1×10⁻⁹ SCCM). Every 12 months, calibrate the module with LAM 810-17004-CAL to maintain accuracy; replace Viton® seals if leaks are detected or if the module is exposed to moisture. Clean the OLED screen monthly with a lint-free wipe and isopropyl alcohol (99.9% purity) to remove cleanroom residue. For small-scale production lines, keep a spare seal kit on hand—target seal replacement time: <30 minutes to minimize tool downtime.

Service and guarantee commitment

LAM Research backs LAM 810-17004-004 with a 1-year standard warranty, covering defects in materials and workmanship for 28nm–90nm semiconductor use (non-fluorinated gas environments only). This warranty includes free replacement of faulty components (e.g., capacitance manometer, display screen) and excludes normal wear items (e.g., seals). Weekday technical support (8 AM–5 PM local time) is provided by LAM’s legacy basic systems team, accessible via the LAM Customer Portal or email, to assist with installation troubleshooting and calibration guidance.

For extended protection, customers can purchase LAM’s Basic Mature-Node Monitoring Support Plan, which extends coverage to 2.5 years and includes: annual remote calibration assistance, discounted replacement parts (20% off list price), and priority technical support (≤8-hour response time). All LAM 810-17004-004 units undergo simplified pre-shipment testing: 24-hour pressure stability checks (maintaining ±3% accuracy at 1×10⁻⁶ Torr), temperature compensation verification (10°C–45°C), and 100% leak rate testing (≤1×10⁻⁹ SCCM). LAM also provides a free 15-minute online training module (“Basic Vacuum Monitoring for Legacy LAM Tools”) to help technicians optimize module use.