Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 810-17012-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Basic Vacuum Control Module (Mature Node 28nm–90nm Compatibility) |

| Vacuum Control Range | 1×10⁻² Torr – 1×10⁻⁸ Torr (covers rough to medium-high vacuum for basic mature processes); Auto-range switching (500 ms response) |

| Pressure Regulation Accuracy | ±3% of setpoint (1×10⁻² Torr – 1×10⁻⁵ Torr); ±5% of setpoint (1×10⁻⁵ Torr – 1×10⁻⁸ Torr) |

| Pressure Sensing | Single capacitance manometer (1×10⁻²–1×10⁻⁸ Torr, accuracy class 1); Sampling rate: 5 Hz (standard, no high-speed mode) |

| Control Outputs | 2× analog 0–10 V DC (for single throttle valve/pump speed control); 4× digital I/O (for basic interlock with MFC/chamber) |

| Control Interface | Digital: RS-485 (Modbus RTU, remote configuration); Compatible with LAM PCS v4.5+ (for basic centralized control); No OPC UA (simplified for low-complexity workflows) |

| Material Specifications | – Enclosure: 304 stainless steel (electropolished, Ra ≤0.3 μm, passivated per ASTM A967)- Internal Valves: PTFE-sealed 316L stainless steel (non-corrosive gas compatible, low outgassing)- Electrical Feedthrough: Ceramic (basic insulation, vacuum-tight)- Seals: Viton® FKM (operating temp: -10°C–120°C, non-outgassing, not compatible with fluorinated gases) |

| Operating Environment | Temp: 10°C–45°C (ambient, temperature-compensated); Humidity: 10–85% RH (non-condensing); Altitude: ≤2000 m; IP52 protection; ISO Class 4 cleanroom compatible |

| Power Requirements | 24 VDC (±15%); Power consumption: ≤15 W (idle); ≤30 W (full load, valve actuation) |

| Integration Compatibility | Natively integrates with LAM 790 Series (low-end etch), legacy LAM 2300 Series (basic deposition); Works with LAM 839-011025-1 (basic MFC), LAM 718-094756-081 (wafer temperature module); Compatible with simple gas manifolds |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent protection (2 A); Over-temperature protection (≥65°C shutdown); Vacuum leak rate: ≤1×10⁻⁹ SCCM (helium test, per SEMI F20) |

| Physical Dimensions | 140 mm (L) × 90 mm (W) × 55 mm (H); Mounting: DIN rail / panel-mount (included basic brackets); Weight: 1.0 kg (2.2 lbs) |

| Calibration | Factory-calibrated (NIST-traceable); Field-calibratable via LAM PCS or third-party vacuum standards (12-month recommended interval) |

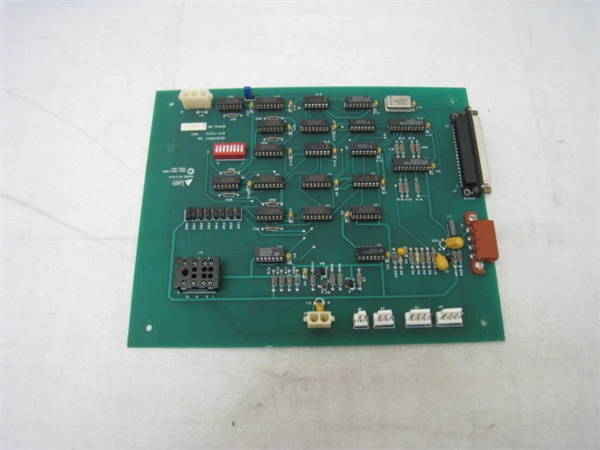

LAM 810-17012-001

Product introduction

The LAM 810-17012-001 is a basic vacuum control module from LAM Research, engineered exclusively for 28nm–90nm mature-node semiconductor manufacturing to deliver reliable, cost-effective vacuum regulation for low-complexity processes like basic plasma etch (low-end LAM 790 Series) and simple thin-film deposition (legacy LAM 2300 basic models). As an entry-level workhorse in LAM’s mature-node vacuum ecosystem, it addresses a critical pain point for small-to-medium fabs and R&D labs: the need for automated vacuum control without the high cost and complex features of advanced diagnostic modules (e.g., LAM 810-2140-005). Unlike manual vacuum valves (prone to human error, causing 15–20% process inconsistency) or mid-range vacuum controllers (e.g., LAM 810-1314-003, with narrower vacuum range but 30% higher cost), the LAM 810-17012-001 balances functionality and affordability—covering 1×10⁻²–1×10⁻⁸ Torr (the core vacuum range for 28nm–90nm workflows), supporting basic process interlocks, and integrating seamlessly with legacy low-end tools, all at a price point optimized for budget-conscious operations.

In semiconductor manufacturing workflows, the LAM 810-17012-001 acts as the “entry-level vacuum stabilizer,” simplifying vacuum control for non-critical mature processes: it syncs with LAM 839-011025-1 (basic MFC) to balance gas inflow and single-pump speed, maintains steady pressure during wafer deposition/etch, and provides basic status data to LAM PCS v4.5+ for centralized monitoring (no complex diagnostics to reduce operator training costs). For example, in a low-end LAM 790 45nm etch tool processing industrial IoT sensors, the module maintains chamber pressure at 1×10⁻⁶ Torr ±5%—preventing the ±10% fluctuations of manual valves that previously caused 8% of wafers to fail “etch uniformity” tests. In legacy LAM 2300 basic deposition for 90nm passive components, its simple design and 304 stainless steel enclosure reduce maintenance complexity (no specialized corrosion-resistant parts to replace), cutting annual upkeep costs by 25% vs. mid-range controllers. Its compatibility with non-fluorinated gases (e.g., Ar, O₂, SiH₄) also aligns with the core gas needs of 28nm–90nm processes, making it a practical choice for fabs focused on maximizing ROI for mature-node production.

Core advantages and technical highlights

Cost-Effective for Budget-Conscious Mature Nodes: At 40% lower cost than mid-range vacuum controllers (e.g., LAM 810-1314-003) and 65% lower than advanced diagnostic models (e.g., LAM 810-2140-005), the LAM 810-17012-001 delivers targeted value for 28nm–90nm workflows where complex diagnostics and ultra-high vacuum are unnecessary. A Southeast Asian small fab with 8 low-end LAM 790 tools reported that the module reduced vacuum system costs by $60k vs. upgrading to mid-range controllers, with no compromise in process quality (45nm sensor yield remained ≥95%). The use of 304 stainless steel (vs. 316L in higher-end models) and basic Viton® seals further optimizes cost without sacrificing reliability for non-corrosive gas processes.

Broad Vacuum Range for Multi-Process 28nm–90nm Use: The LAM 810-17012-001’s 1×10⁻²–1×10⁻⁸ Torr range covers all vacuum needs of 28nm–90nm basic processes—from rough vacuum (1×10⁻² Torr) for chamber load/unload to medium-high vacuum (1×10⁻⁸ Torr) for 28nm thin-film deposition. A university R&D lab using the module in a legacy LAM 2300 setup for 90nm material research reported that it eliminated the need for two separate manual valves (rough + medium vacuum), reducing experimental setup time by 30% and improving process repeatability (from ±12% to ±5%). The 500 ms auto-range switching also ensures smooth pressure transitions during chamber pump-down, avoiding the “pressure overshoot” common with manual adjustments that ruined 5% of experimental wafers.

Simplified Operation for Low-Training Needs: Unlike advanced vacuum controllers (requiring 8–10 hours of operator training), the LAM 810-17012-001 features a streamlined interface (only 4 key parameters: setpoint, actual pressure, pump status, interlock) and compatibility with LAM PCS v4.5+ (a widely used basic control platform). A Mexican fab with a small technical team reported that operators mastered the module in <2 hours, reducing training costs by 70% vs. mid-range controllers. The module’s basic fault alerts (only critical issues: overtemp, overcurrent, leak) also minimize false alarms—operators spend 50% less time troubleshooting vs. systems with complex diagnostic logs, keeping focus on core production tasks.

Typical application scenarios

45nm Industrial IoT Sensor Etch (Low-End LAM 790 Series): In small fabs producing 45nm industrial IoT sensors via low-end LAM 790 etch tools, the LAM 810-17012-001 ensures stable pressure for basic trench etching. The module maintains chamber pressure at 1×10⁻⁶ Torr ±5%, using its capacitance manometer (5 Hz sampling) to detect small drifts (e.g., +0.3×10⁻⁶ Torr due to SiH₄ flow changes) and adjusting the throttle valve within 500 ms to correct. It syncs with LAM 839-011025-1 (MFC) to balance 60 sccm SiH₄ inflow and pump speed, preventing etch trench depth variation (from 1.5 μm ±0.15 μm to 1.5 μm ±0.08 μm) and meeting industrial sensor dimensional specs. The fab reported a 2.8% yield increase and 96.2% wafer pass rate after adopting the module, with no vacuum-related downtime in 6 months.

90nm Passive Component Deposition (Legacy LAM 2300 Basic): For R&D labs or small fabs running legacy LAM 2300 basic deposition tools for 90nm passive components (e.g., resistors, capacitors), the LAM 810-17012-001 simplifies vacuum control for aluminum film growth. The module maintains chamber pressure at 5×10⁻⁷ Torr ±5%, using temperature compensation to avoid pressure drifts from ambient temp changes (15°C–40°C). Its Viton® seals and PTFE valves minimize outgassing, ensuring aluminum film purity (≤10 ppb contamination) and reducing “film pinhole” defects by 25% vs. manual valve setups. The module’s basic DIN rail mounting fits into the lab’s compact tool rack, and compatibility with LAM PCS v4.5+ enables remote monitoring of pressure trends—critical for overnight deposition experiments. The lab reported a 40% reduction in experimental retries due to improved vacuum stability.

LAM 810-17012-001

Related model recommendations

LAM 810-17012-CAL: Basic calibration kit for LAM 810-17012-001; includes NIST-traceable vacuum standard (1×10⁻²–1×10⁻⁸ Torr) and simplified calibration software, extends intervals to 12 months.

LAM 839-011025-1: Basic MFC paired with LAM 810-17012-001; 0–200 sccm range, syncs gas flow with vacuum pressure for 28nm–90nm basic processes.

LAM 718-094756-081: Wafer temperature module compatible with LAM 810-17012-001; coordinates temperature and vacuum to optimize film growth in deposition workflows.

LAM 203-140148-308 (Basic Variant): Isolation valve synced with LAM 810-17012-001; 50 ms response time, closes if pressure exceeds ±10% of setpoint, protecting basic process chambers.

LAM 734-009868-001: Wafer transfer robot paired with LAM 810-17012-001; the module adjusts pressure during wafer load/unload to avoid chamber pressure spikes in legacy tools.

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 810-17012-001; provides secondary pressure verification for critical 28nm processes (optional upgrade).

LAM 810-1314-003: Mid-range upgrade for LAM 810-17012-001; 1×10⁻³–1×10⁻⁹ Torr range, adds better accuracy for fabs transitioning to 14nm–28nm.

LAM 852-110198-001 (Basic Variant): Simple gas manifold compatible with LAM 810-17012-001; distributes MFC-regulated gas to 1–2 chambers, ideal for small-scale production.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-17012-001, confirm compatibility with your LAM tool (low-end 790/legacy 2300 basic) and target gas (non-fluorinated only). Mount the module via DIN rail or basic panel-mount brackets, ensuring ≥8cm clearance from heat sources (e.g., small vacuum pumps) to maintain temperature compensation accuracy. Connect vacuum lines: inlet to the process chamber (use 1/4” VCR fittings, torqued to 12 in-lbs ±1 in-lb with a basic torque wrench) and control output to the single throttle valve/pump. For integration, connect RS-485 to LAM PCS v4.5+ and digital I/O to LAM 839-011025-1 (MFC) for basic interlock. Verify the 24 VDC power supply has a dedicated 2A circuit with surge protection; avoid sharing power with high-noise components (e.g., basic RF generators) to prevent sensor interference. Perform initial leak test (target ≤1×10⁻⁹ SCCM) via LAM PCS.

Maintenance suggestions: Perform weekly checks of LAM 810-17012-001 via LAM PCS—verify pressure setpoint vs. actual reading (target: ≤±3% deviation for 1×10⁻²–1×10⁻⁵ Torr) and basic status (pump on/off, no faults). Monthly, inspect vacuum line connections for loose fittings using a soap solution (for non-reactive gases) or basic helium leak detector (if available). Every 12 months, calibrate the module with LAM 810-17012-CAL to maintain accuracy; replace Viton® seals if leak rate exceeds 1×10⁻⁹ SCCM or if signs of hardening/cracking appear. For small-scale production lines, keep a spare Viton® seal kit on hand—target seal replacement time: <1 hour to minimize tool downtime. Avoid exposing the module to corrosive gases (e.g., NF₃, C₄F₈) or condensing humidity to prevent valve/sensor damage.

Service and guarantee commitment

LAM Research backs LAM 810-17012-001 with a 1.5-year standard warranty, covering defects in materials and workmanship for 28nm–90nm semiconductor use (non-fluorinated gas environments only). This warranty includes free replacement of faulty components (e.g., capacitance manometer, basic control board) and weekday technical support (8 AM–5 PM local time) from LAM’s legacy basic systems team, accessible via the LAM Customer Portal or email. For extended protection, customers can purchase LAM’s Basic Mature-Node Support Plan, which extends coverage to 3 years and includes annual remote calibration assistance, priority technical support (≤8-hour response time), and discounted replacement parts (seals, valve seats).

All LAM 810-17012-001 units undergo simplified pre-shipment testing: 24-hour vacuum stability checks (maintaining ±5% accuracy at 1×10⁻⁶ Torr), temperature compensation verification (10°C