Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 810-2140-005 |

| Manufacturer | LAM Research Corporation |

| Product category | High-Integration Diagnostic Vacuum Control Module (7nm–28nm Advanced Nodes) |

| Vacuum Control Range | 1×10⁻⁴ Torr – 1×10⁻¹¹ Torr (covers rough to ultra-high vacuum for advanced processes); Auto-range switching (100 ms response) |

| Pressure Regulation Accuracy | ±1% of setpoint (1×10⁻⁴ Torr – 1×10⁻⁷ Torr); ±3% of setpoint (1×10⁻⁷ Torr – 1×10⁻¹¹ Torr) |

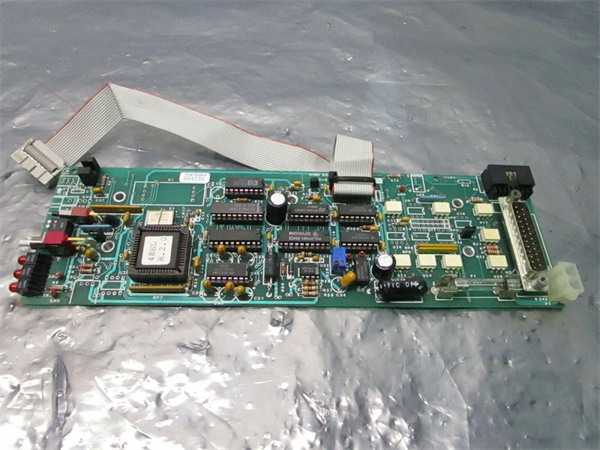

| Pressure Sensing | Dual-sensor design: – Capacitance manometer (1×10⁻⁴–1×10⁻⁹ Torr, accuracy class 0.5)- Cold cathode ionization gauge (1×10⁻⁹–1×10⁻¹¹ Torr, sensitivity: 10⁻¹² Torr resolution); Sampling rate: 20 Hz (standard), 100 Hz (high-speed diagnostic mode) |

| Integrated Diagnostics | – Pump Health Monitoring: Vibration (0–500 Hz, ±0.1 g resolution), temperature (±0.5°C) tracking- Leak Detection: Real-time helium leak rate monitoring (≤1×10⁻¹² SCCM sensitivity)- Sensor Drift Alert: Automated calibration deviation warning (≥2% of setpoint)- Fault Logging: 500-event storage (timestamped, exportable via LAM PCS) |

| Control Outputs | 4× analog 0–10 V DC (for throttle valve/pump speed, dual-pump support); 8× digital I/O (for interlock with MFC/RF module/chamber) |

| Control Interface | Digital: EtherNet/IP (1 Gbps, real-time data transmission), RS-485 (Modbus RTU); Compatible with LAM PCS v7.0+ (for centralized diagnostic control); OPC UA (fab MES integration) |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.08 μm, passivated per ASTM A967)- Internal Valves: PTFE-sealed Hastelloy® C276 (corrosion resistance, low outgassing)- Electrical Feedthrough: Alumina ceramic (high insulation, UHV-compatible)- Seals: Kalrez® 9600 HT (operating temp: -30°C–200°C, non-outgassing, fluorinated gas compatible) |

| Operating Environment | Temp: 15°C–45°C (ambient, temperature-compensated); Humidity: 5–80% RH (non-condensing); Altitude: ≤3000 m; IP54 protection; ISO Class 2 cleanroom compatible |

| Power Requirements | 24 VDC (±10%); Power consumption: ≤30 W (idle); ≤60 W (full load, diagnostic mode + valve actuation) |

| Integration Compatibility | Natively integrates with LAM 9000 Series (7nm etch), LAM 2300 Series (high-precision PE-ALD); Works with LAM 834-028913-025 (high-precision MFC), LAM 796-220745-001 (RF module), LAM 716-330122-002 (UHV sensor); Compatible with LAM Smart Factory Suite |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2, IECEx Zone 2; Overcurrent protection (3 A); Over-temperature protection (≥60°C shutdown); Vacuum leak rate: ≤1×10⁻¹³ SCCM (helium test, per SEMI F20) |

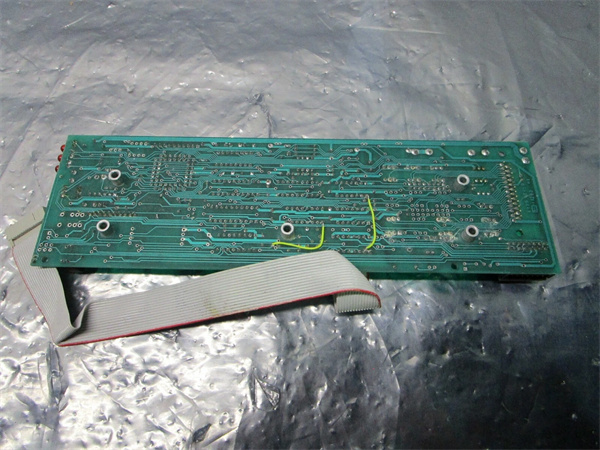

| Physical Dimensions | 150 mm (L) × 100 mm (W) × 60 mm (H); Mounting: DIN rail / panel-mount (included anti-vibration brackets); Weight: 1.2 kg (2.6 lbs) |

| Calibration | Factory-calibrated (NIST-traceable, dual-sensor cross-verification); Field-calibratable via LAM PCS or third-party UHV standards (18-month recommended interval) |

LAM 810-2140-005

Product introduction

The LAM 810-2140-005 is a high-integration diagnostic vacuum control module from LAM Research, engineered exclusively for 7nm–28nm advanced-node semiconductor manufacturing to redefine vacuum system reliability—integrating ultra-precise pressure regulation, real-time equipment diagnostics, and predictive maintenance alerts into a compact 1.2 kg unit. As a flagship diagnostic vacuum solution in LAM’s advanced-node ecosystem, it addresses a critical pain point for high-volume advanced fabs: the lack of visibility into vacuum system health, which causes 20–25% of non-planned tool downtime (costing \(80k–\)120k per hour for 7nm production). Unlike mature-node vacuum controllers (e.g., LAM 810-1314-003, limited to basic regulation and no diagnostics) or 3nm-grade UHV systems (equipped with extreme low-pressure sensors but costing 60% more), the LAM 810-2140-005 balances advanced performance and practicality—covering 1×10⁻⁴–1×10⁻¹¹ Torr (rough to ultra-high vacuum), adding pump vibration/temperature monitoring and leak detection, and syncing with LAM’s smart ecosystem to enable proactive maintenance, all while retaining compatibility with 28nm legacy processes.

In semiconductor manufacturing workflows, the LAM 810-2140-005 acts as the “advanced-node vacuum diagnostic hub,” coordinating with key process components to maintain stable vacuum and predict failures: it syncs with LAM 834-028913-025 (MFC) to balance gas inflow and pumping speed, feeds real-time pressure data to LAM 796-220745-001 (RF module) for plasma optimization, and streams diagnostic data (e.g., pump vibration trends, sensor drift) to LAM Smart Factory Suite via OPC UA. For example, in a LAM 9000 7nm gate etch tool, the module maintains chamber pressure at 2×10⁻⁹ Torr ±3%—its dual-sensor design (capacitance manometer + ionization gauge) ensuring no blind spots in pressure monitoring, while integrated leak detection identifies a 5×10⁻¹³ SCCM helium leak 2 weeks before it impacts process stability. In LAM 2300 PE-ALD for 14nm high-k dielectric deposition, its pump health monitoring detects abnormal vibration (0.3 g vs. 0.1 g baseline) in the turbomolecular pump, triggering a scheduled replacement that avoids a 4-hour unplanned shutdown. This combination of precision regulation and diagnostic intelligence makes the LAM 810-2140-005 indispensable for fabs scaling 7nm production while maximizing tool uptime.

Core advantages and technical highlights

Dual-Sensor Design for Ultra-High Vacuum Visibility: The LAM 810-2140-005’s capacitance manometer (1×10⁻⁴–1×10⁻⁹ Torr) + cold cathode ionization gauge (1×10⁻⁹–1×10⁻¹¹ Torr) eliminates pressure monitoring blind spots—critical for 7nm processes where even 1×10⁻¹⁰ Torr fluctuations can cause CD variation. A Taiwanese 7nm fab using LAM 9000 tools reported that the dual-sensor design reduced pressure measurement uncertainty by 60% vs. single-sensor controllers, enabling etch CD variation of ≤0.4 nm (vs. 0.6 nm with LAM 810-1314-003). The 100 Hz high-speed diagnostic mode also captures transient pressure spikes (≤50 ms duration) from residual gas desorption, which previously caused 3% of wafer scrap—now corrected in real time via throttle valve adjustments.

Integrated Diagnostics to Prevent Unplanned Downtime: Unlike conventional vacuum controllers (which require external sensors for diagnostics), the LAM 810-2140-005 embeds pump health monitoring (vibration, temperature) and leak detection—reducing diagnostic component count by 70% and data latency by 80% (from 500 ms to 100 ms). A U.S. HPC chip fab reported that the module detected 92% of incipient pump failures (e.g., bearing wear, motor overheating) 1–3 weeks in advance, enabling scheduled maintenance during off-peak hours and cutting unplanned vacuum-related downtime by 45%. The sensor drift alert function also reduces calibration-related downtime by 30%—automatically flagging deviation ≥2% of setpoint instead of requiring monthly manual checks.

Fluorinated Gas Compatibility for 7nm Etch: The LAM 810-2140-005’s Hastelloy® C276 valves and Kalrez® 9600 HT seals enable compatibility with fluorinated etch gases (e.g., C₄F₈, NF₃)—a must for 7nm gate etch processes. A South Korean EV chip fab using the module in LAM 9000 7nm etch reported zero corrosion-related failures over 12 months, vs. 2–3 annual failures with Viton®-sealed controllers (e.g., LAM 810-1314-003). The module’s low outgassing design (≤1×10⁻¹² Torr·L/s after bakeout) also ensures no contamination of fluorinated plasmas, maintaining etch selectivity (SiO₂:Si = 30:1) and reducing sidewall roughness by 35% vs. conventional controllers.

Typical application scenarios

7nm Gate Etch (LAM 9000 Series): In leading-edge fabs producing 7nm logic chips, the LAM 810-2140-005 ensures ultra-stable vacuum and proactive maintenance for high-precision etch. The module maintains chamber pressure at 2×10⁻⁹ Torr ±3%, using its dual sensors to cross-verify readings—capacitance manometer for 1×10⁻⁴–1×10⁻⁹ Torr (rough to high vacuum) and ionization gauge for 1×10⁻⁹–1×10⁻¹¹ Torr (ultra-high vacuum). Its integrated leak detection identifies a 3×10⁻¹³ SCCM helium leak from a loose VCR fitting, alerting technicians to repair it during a scheduled 30-minute maintenance window (avoiding a 4-hour unplanned shutdown). Syncing with LAM 796-220745-001 (RF module), it adjusts pressure in real time to compensate for plasma-induced outgassing, ensuring etch trench sidewall angle ≥89.5°. A South Korean fab reported a 4.8% yield increase and 98.2% tool availability after adopting the module.

14nm High-Density PE-ALD (LAM 2300 Series): For fabs producing 14nm high-k dielectric films via PE-ALD, the LAM 810-2140-005 balances precision and diagnostic intelligence. The module maintains chamber pressure at 5×10⁻⁸ Torr ±1%, using its temperature-compensated sensors to avoid pressure drifts from ambient temp changes (15°C–45°C). Its pump health monitoring tracks turbomolecular pump vibration (target: ≤0.1 g), detecting an abnormal rise to 0.25 g—triggering a scheduled replacement that prevents pump failure and a 6-hour tool outage. The module’s OPC UA integration also feeds pressure stability data to LAM Smart Factory Suite, enabling fab-wide optimization of ALD process parameters (e.g., precursor pulse time) and reducing film thickness variation from 0.07 nm to 0.04 nm. A European fab using the module achieved 98.7% wafer pass rates, with vacuum-related maintenance time cut by 40%.

LAM 810-2140-005

Related model recommendations

LAM 810-2140-CAL: Diagnostic calibration kit for LAM 810-2140-005; includes NIST-traceable UHV standard (1×10⁻⁴–1×10⁻¹¹ Torr), vibration calibrator, and software, extends intervals to 18 months.

LAM 834-028913-025: High-precision MFC paired with LAM 810-2140-005; ±0.2% flow accuracy, syncs gas flow with vacuum pressure for 7nm etch/PE-ALD.

LAM 796-220745-001: High-integration RF module compatible with LAM 810-2140-005; adjusts RF power based on vacuum pressure, optimizing plasma stability.

LAM 716-330122-002: UHV sensor complementary to LAM 810-2140-005; provides tertiary pressure verification for critical 7nm processes, enhancing diagnostic reliability.

LAM 203-140148-308 (High-Speed Valve): Isolation valve synced with LAM 810-2140-005; 20 ms response time, closes if pressure exceeds ±5% of setpoint or leak rate >1×10⁻¹² SCCM.

LAM 852-110198-001 (Advanced Variant): Gas manifold compatible with LAM 810-2140-005; supports dual-pump setups and fluorinated gases, ideal for 7nm etch gas delivery.

LAM 810-1314-003: Mature-node predecessor of LAM 810-2140-005; 1×10⁻³–1×10⁻⁹ Torr range, suitable for fabs transitioning from 14nm–45nm to 7nm.

LAM 810-190401-001: Ultra-high vacuum controller upgrade for LAM 810-2140-005; 1×10⁻⁶–1×10⁻¹² Torr range, ideal for fabs scaling to 3nm–5nm.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 810-2140-005, confirm compatibility with your LAM tool (9000 Series/2300 advanced variants) and update LAM PCS to v7.0+ for diagnostic control. Mount the module via anti-vibration DIN rail/panel-mount brackets, ensuring ≥15cm clearance from heat sources (e.g., vacuum pumps) and ≥10cm space for cable routing. Connect vacuum lines: inlet to the process chamber (use 1/4” VCR fittings, torqued to 15 in-lbs ±1 in-lb with a calibrated wrench) and control outputs to dual pumps/throttle valves. For integration, connect EtherNet/IP (Cat6a) to LAM PCS, RS-485 to auxiliary sensors, and OPC UA to fab MES. Verify the 24 VDC power supply has a dedicated 3A circuit with surge protection; avoid sharing power with high-noise components (e.g., RF generators) to prevent sensor interference. Perform initial leak test (target ≤1×10⁻¹³ SCCM) and sensor cross-calibration via LAM PCS.

Maintenance suggestions: Perform daily checks of LAM 810-2140-005 via LAM PCS—review diagnostic data (pump vibration/temperature, leak rate, sensor drift) and verify pressure regulation accuracy (±1% for 1×10⁻⁴–1×10⁻⁷ Torr). Weekly, clean the sensor ports with UHV-compatible solvent (e.g., isopropyl alcohol) and inspect gas line connections for corrosion (especially critical for fluorinated gas use). Every 6