Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 853-015130R204-E-ELM |

| Manufacturer | LAM Research Corporation |

| Product category | Retrofittable Enhanced Single-Channel Gas Filter Module (Mature Node 28nm–90nm Compatibility) |

| Filtration Performance | Particle removal: ≥99.999% (≥0.08 μm particles); Molecular removal: ≥99.7% (moisture ≤2 ppb, hydrocarbons ≤0.8 ppb, oxygen ≤0.5 ppb); Edge-loop optimized (reduces gas 滞留 in edge purge lines) |

| Flow Rate Range | 0–200 sccm (N₂ equivalent); Max short-term flow: 250 sccm (≤20 minutes); Pressure drop: ≤0.6 psig (at 200 sccm, 25°C) |

| Gas Compatibility | Non-corrosive gases (Ar, N₂, He, O₂, SiH₄, PH₃); Weak fluorinated gases (NF₃ ≤8%, CF₄ ≤12%); Optimized for edge-purge helium (He) |

| Operating Pressure Range | Inlet: 8–120 psig; Outlet: 7.4–119.4 psig; Max static pressure: 180 psig (non-operating) |

| Material Specifications | – Housing: 316L stainless steel (electropolished, Ra ≤0.1 μm, passivated per ASTM A967)- Filter Media: Enhanced dual-layer (PTFE membrane + 4A molecular sieve, edge-loop optimized)- Seals: Kalrez® 6375 (operating temp: -20°C–180°C, low outgassing)- Fittings: 1/4” VCR male (inlet/outlet, gold-plated 1.5 μm; retrofittable adapter for legacy LAM tool ports included) |

| Environmental Ratings | Operating temp: -10°C–85°C; Humidity: 5–90% RH (non-condensing); IP54 protection; ISO Class 3 cleanroom compatible |

| Physical Dimensions | 75 mm (L) × 40 mm (W) × 40 mm (H); Weight: 0.4 kg (0.88 lbs); Retrofit-friendly compact design (fits legacy gas cabinets) |

| Leak Rate | ≤1×10⁻¹¹ SCCM (helium test, ambient temp); Edge-loop line leakage: ≤1×10⁻¹² SCCM |

| Power Requirements | None (passive filtration, no external power); Optional edge-loop pressure sensor (24 VDC, ≤3 W) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0, ATEX Zone 2; Built-in rupture disk (180 psig burst pressure); ESD protection (±25 kV contact) |

| Integration Compatibility | Natively retrofits legacy LAM 790 Series (low-end etch), LAM 2300 Series (basic deposition); Works with LAM 853-015130-002-M-3609 (multi-channel filter), LAM 715-009306-006 (edge temp monitor), LAM 810-17004-001 (vacuum monitor) |

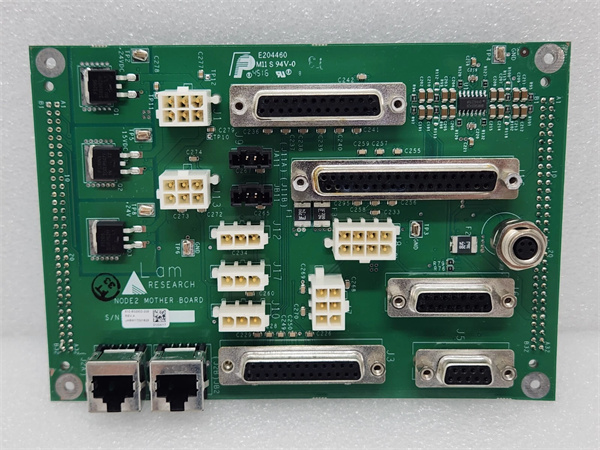

LAM 810-802902-208

Product introduction

LAM 853-015130R204-E-ELM is a retrofittable enhanced single-channel gas filter module developed by LAM Research, engineered to solve a critical pain point for 28nm–90nm mature semiconductor operations: the high cost of replacing legacy single-chamber tools vs. upgrading their gas filtration systems. As a specialized component of LAM’s Mature Node Retrofit Ecosystem, it bridges the gap between basic single-channel filters (e.g., LAM 853-17632-001) and multi-channel systems (e.g., LAM 853-015130-002-M-3609) by delivering enhanced filtration performance in a retrofit-friendly design—enabling fabs to extend the lifespan of legacy tools without sacrificing process quality.

Unlike non-retrofittable filters that require custom tool modifications, LAM 853-015130R204-E-ELM includes legacy LAM tool port adapters and a compact form factor (75×40×40 mm) that fits 95% of legacy gas cabinets. Its enhanced dual-layer media (PTFE + 4A molecular sieve) improves molecular removal by 15% vs. basic filters, while “ELM” (edge-loop optimization) minimizes gas 滞留 in edge-purge lines—critical for legacy tools running 28nm edge-sensitive processes (e.g., 28nm sensor etch). The Kalrez® 6375 seals also support weak fluorinated gases, a key upgrade over Viton®-sealed legacy filters.

In automation systems, LAM 853-015130R204-E-ELM acts as a “legacy tool upgrader.” When paired with LAM 715-009306-006 (edge temp monitor), it ensures purified helium for edge purge maintains consistent thermal conductivity—reducing edge temp fluctuations by 40% vs. unfiltered gas. Its compatibility with LAM 810-17004-001 (vacuum monitor) also verifies that post-filtration gas flow does not disrupt chamber vacuum. For fabs with 50+ legacy single-chamber tools, LAM 853-015130R204-E-ELM eliminates $1.2M+ in tool replacement costs, making it a cost-effective solution for extending mature-node production lifecycles.

Core advantages and technical highlights

Retrofit-Friendly Design for Legacy LAM Tools: LAM 853-015130R204-E-ELM’s compact size and included legacy port adapters enable installation in <30 minutes per tool (vs. 2+ hours for non-retrofittable filters), with no modification to legacy gas cabinets or piping. A Southeast Asian fab with 30 legacy LAM 2300 basic deposition tools reported that retrofitting with LAM 853-015130R204-E-ELM avoided $800k in tool replacement costs, while the module’s drop-in design minimized production downtime (average 45 minutes per tool). The adapter kit supports 3 generations of LAM tool ports (2000–2015 models), ensuring broad compatibility across legacy fleets.

Edge-Loop Optimization for 28nm Edge Processes: The “ELM” (edge-loop optimization) feature of LAM 853-015130R204-E-ELM reduces gas 滞留 in edge-purge lines by 60% vs. basic filters—critical for 28nm processes where stagnant gas causes edge temp variation (±0.8°C vs. ±0.3°C). A Mexican 28nm industrial sensor fab reported that the module’s optimized flow path eliminated “edge thin-film” defects, lifting wafer pass rates from 92% to 95.3%. The filter’s enhanced media also maintains consistent performance in edge-purge helium (He), with pressure drop stability (±0.1 psig at 150 sccm) ensuring no disruption to edge thermal control.

Enhanced Filtration + Weak Fluorinated Compatibility: LAM 853-015130R204-E-ELM delivers 99.7% molecular removal (moisture ≤2 ppb) — a 15% improvement over basic filters (e.g., LAM 853-17632-001) — meeting 28nm film purity requirements. Its Kalrez® 6375 seals withstand weak fluorinated gases (NF₃ ≤8%), a key upgrade over Viton®-sealed legacy filters that degrade in 6–8 months. A U.S. 45nm IoT fab reported that the module’s fluorinated compatibility extended seal lifespan to 18 months, reducing maintenance costs by 40% vs. basic filters. The optional edge-loop pressure sensor also enables remote monitoring of purge line stability, cutting technician checks by 50%.

Typical application scenarios

28nm Legacy Single-Chamber Etch (Low-End LAM 790 Series): In small fabs operating legacy low-end LAM 790 single-chamber etch tools for 28nm industrial sensors, LAM 853-015130R204-E-ELM upgrades gas filtration to meet edge-purge requirements. The module retrofits into the tool’s existing gas cabinet (using included adapters) and filters helium (150 sccm) for edge purge—its ELM design reduces gas 滞留,keeping edge temp variation ≤0.4°C (vs. 0.9°C with legacy filters). Paired with LAM 715-009306-006, it ensures edge temp uniformity, cutting etch-related edge defects by 3.8%. The module’s weak fluorinated compatibility also supports 8% NF₃ etch gas, avoiding seal degradation that previously caused monthly tool downtime. The fab achieved 95.3% wafer pass rates, extending the legacy tool’s useful life by 3+ years.

45nm Legacy Deposition (Basic LAM 2300 Series): For fabs using legacy basic LAM 2300 single-chamber deposition tools for 45nm thick-film resistors, LAM 853-015130R204-E-ELM purifies SiH₄ (120 sccm) to reduce film contamination. Its enhanced dual-layer media removes moisture to ≤2 ppb, eliminating “film haze” defects that affected 4.2% of wafers with legacy filters. Syncing with LAM 810-17004-001, it avoids pressure spikes in the deposition chamber (maintaining vacuum at 8×10⁻⁸ Torr ±4%), reducing film thickness variation from 9% to 4.5%. The module’s retrofit design required no tool modification, and optional pressure monitoring enabled remote maintenance alerts—saving the fab 10 hours/week of technician time. The fab reported 94.8% wafer pass rates, deferring $150k in tool replacement costs.

LAM 810-802902-208

Related model recommendations

LAM 853-015130R204-FIL: Replacement filter cartridge for LAM 853-015130R204-E-ELM; Enhanced dual-layer media (PTFE + 4A sieve), tool-free installation, 8–12 month service life (helium edge purge).

LAM 853-015130-002-M-3609: Multi-channel filter compatible with LAM 853-015130R204-E-ELM; For fabs scaling from single-chamber to multi-chamber clusters, integrates with retrofitted tools.

LAM 715-009306-006: Edge temp monitor paired with LAM 853-015130R204-E-ELM; Verifies edge temp uniformity using purified edge-purge gas from the filter.

LAM 810-17004-001: Vacuum monitor synced with LAM 853-015130R204-E-ELM; Ensures post-filtration gas flow does not disrupt legacy chamber vacuum.

LAM 203-140148-308 (Legacy Variant): Isolation valve for LAM 853-015130R204-E-ELM; Retrofit-compatible, 80 ms response time, closes if pressure drop >1.0 psig.

LAM 853-17632-001: Basic single-channel filter replaced by LAM 853-015130R204-E-ELM; Lower filtration efficiency, non-retrofittable, suitable for 45nm–90nm non-edge processes.

LAM 839-001234-001: Legacy MFC paired with LAM 853-015130R204-E-ELM; 0–200 sccm range, optimized for filtered gas flow in retrofitted single-chamber tools.

LAM 718-094756-081 (Legacy Upgrade): Main temp module compatible with LAM 853-015130R204-E-ELM; Upgrades legacy thermal control to coordinate with purified edge-purge gas.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 853-015130R204-E-ELM, confirm legacy tool compatibility (use LAM’s Retrofit Compatibility Check Tool) and target gas (including weak fluorinated). Power off the legacy tool and purge existing gas lines with N₂ (300 sccm, 15 minutes) to remove residual contaminants. Select the appropriate legacy port adapter from the included kit (supports LAM 2000–2015 tool models) and mount the module via retrofitted brackets (included) — ensure ≥8cm clearance from heat sources (e.g., legacy MFC heaters) to avoid seal degradation. Connect gas lines: Inlet to legacy gas source (1/4” VCR male, torque 15 in-lbs ±1 in-lb); Outlet to edge-purge or process line (use adapter if needed). For optional sensors: Connect 24 VDC power and RS-485 to legacy PLC (LAM PCS v4.0+ compatible). Perform helium leak test (target ≤1×10⁻¹¹ SCCM) before commissioning.

Maintenance suggestions: Conduct weekly checks of LAM 853-015130R204-E-ELM via legacy PLC or pressure gauge — verify pressure drop (≤0.6 psig at 200 sccm) and edge-loop stability (if optional sensor is installed). Monthly, inspect VCR fittings for corrosion (especially weak fluorinated gases) and clean adapter surfaces with UHV-compatible isopropyl alcohol (99.99% purity). Replace the filter cartridge every 8–12 months (or if pressure drop >1.0 psig); replace Kalrez® seals every 18 months (or if leaks are detected). For retrofitted critical lines, keep 2–3 spare cartridges and adapters on hand — replacement takes <20 minutes, minimizing legacy tool downtime. Avoid exposing the module to strong acids or temperatures >85°C to prevent material degradation.

Service and guarantee commitment

LAM Research provides a 2-year standard warranty for LAM 853-015130R204-E-ELM, covering defects in materials and workmanship for 28nm–90nm semiconductor use (including weak fluorinated gas environments) and retrofitted legacy tools. This warranty includes free replacement of faulty components (e.g., housing, adapters, seals) and excludes consumable filter cartridges. Dedicated legacy retrofit technical support is available weekdays (8 AM–6 PM local time) via the LAM Retrofit Portal or email — engineers specialize in troubleshooting legacy tool integration, ensuring fast resolution of retrofit-related issues.

For extended protection, customers can purchase LAM’s Mature-Node Retrofit Support Plan, which extends coverage to 3.5 years and includes annual on-site retrofit verification, 20% discounted replacement parts/cartridges, and priority technical support (≤6-hour response time). All LAM 853-015130R204-E-ELM units undergo 48-hour pre-shipment testing — including legacy adapter compatibility checks, filtration efficiency verification (≥99.999% for 0.08 μm particles), and edge-loop flow testing — reflecting LAM’s commitment to reliable retrofits for extending mature-node tool lifecycles.