Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 853-017805-55 |

| Manufacturer | LAM Research Corporation |

| Product category | Multi-Channel Medium-Flow Gas Filter & Distribution Module (Mature Node 14nm–45nm Compatibility) |

| Channel Configuration | 4 independent channels (1 inlet, 4 outlets); Each channel with dedicated filter + flow indicator |

| Filtration Capability | Particle removal: ≥99.999% (≥0.05 μm particles); Molecular removal: ≥99.8% (moisture, hydrocarbons, oxygen); Filtration media: Triple-layer (PTFE membrane + activated alumina + molecular sieve) |

| Gas Compatibility | Non-corrosive gases (N₂, Ar, He, O₂, SiH₄); Weakly corrosive gases (low-concentration NF₃ ≤5%, CF₄ ≤10%); Not compatible with high-concentration fluorinated gases (C₄F₈, SF₆) |

| Flow Rate Range | Per channel: 0–500 sccm (N₂ equivalent); Total system: 0–2000 sccm; Pressure drop: ≤1.0 psig (per channel, 500 sccm, 25°C) |

| Operating Pressure Range | Inlet: 10–150 psig; Outlet: 9–149 psig; Max static pressure: 200 psig (non-operating) |

| Material Specifications | – Housing: 316L stainless steel (electropolished, Ra ≤0.1 μm, passivated per ASTM A967, corrosion-resistant)- Filter Media: PTFE (0.05 μm pore) + activated alumina (moisture) + 13X molecular sieve (hydrocarbons)- Seals: Kalrez® 6375 (operating temp: -20°C–180°C, low outgassing, weak corrosion resistance)- Fittings: 1/4” VCR male (inlet), 1/4” VCR female (outlets); Gold-plated, leak-tight per SEMI F20 |

| Operating Temperature Range | Continuous: 10°C–100°C; Peak: 150°C (≤60 minutes); Optional integrated heater (100W, 50°C–120°C adjustable) |

| Dead Volume | Per channel: ≤0.3 cm³; Total system: ≤1.5 cm³ (minimizes gas 滞留,ideal for medium-flow switching) |

| Leak Rate | Per channel: ≤1×10⁻¹¹ SCCM (helium test, ambient temp); Cross-channel leakage: ≤1×10⁻¹² SCCM |

| Environmental Ratings | Operating humidity: 5–90% RH (non-condensing); Storage temp: -30°C–180°C; IP54 protection; ISO Class 3 cleanroom compatible |

| Power Requirements | Base model: None (passive filtration); With optional heater: 24 VDC (±10%), ≤100 W |

| Integration Compatibility | Natively integrates with LAM 790 Series (mainstream etch), LAM 2300 Series (standard deposition); Works with LAM 839-011025-1 (basic MFC), LAM 810-1314-003 (mid-range vacuum controller); Compatible with LAM PCS v5.0+ (for flow status monitoring) |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2; Pressure relief: Built-in rupture disk (200 psig burst pressure); ESD protection (±25 kV contact, housing grounded) |

| Physical Dimensions | 200 mm (L) × 120 mm (W) × 80 mm (H); Mounting: Panel-mount / DIN rail (included anti-vibration brackets); Weight: 2.8 kg (6.2 lbs) (base model); 3.2 kg (7.1 lbs) (with heater) |

| Media Replacement Interval | Recommended: 9 months (continuous use, 300 sccm per channel); Extendable to 15 months (low-flow ≤100 sccm); Replaceable cartridge per channel: LAM 853-017805-FIL |

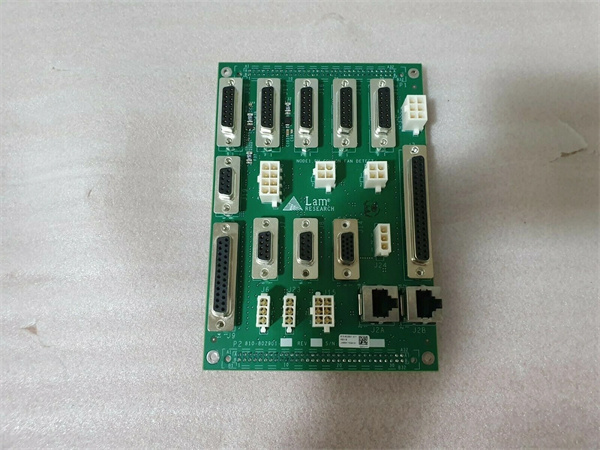

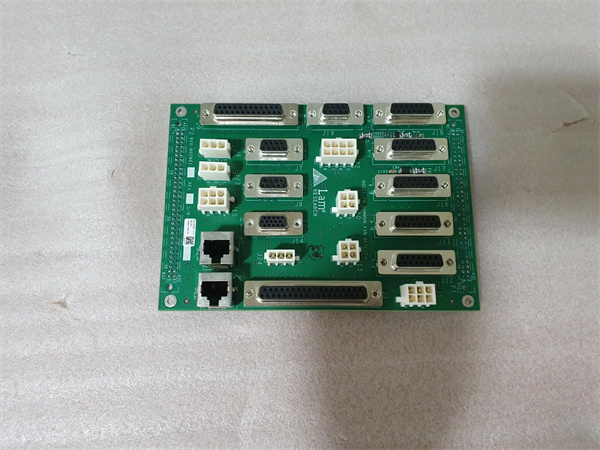

LAM 810-802901-317

Product introduction

The LAM 853-017805-55 is a multi-channel medium-flow gas filter & distribution module from LAM Research, engineered exclusively for 14nm–45nm mature-node semiconductor manufacturing to deliver efficient, corrosion-resistant gas purification and multi-path distribution for medium-complexity processes like mainstream plasma etch (LAM 790 Series) and standard thin-film deposition (LAM 2300 Series). As a mid-range gas handling solution in LAM’s mature-node ecosystem, it addresses a critical pain point for medium-scale fabs: the inefficiency of single-channel filters (requiring 4+ units for multi-gas workflows) and the high cost of advanced multi-channel systems (e.g., LAM 853-491746-100) that support high-concentration fluorides. Unlike single-channel filters (e.g., LAM 853-17632-001, low flow, no distribution) or high-end corrosion-resistant modules (40% higher cost, overqualified for 14nm–45nm weak fluorides), the LAM 853-017805-55 balances functionality and cost—integrating 4 independent filter channels, supporting 0–500 sccm per channel, handling low-concentration fluorides, and enabling centralized gas distribution, all while retaining compatibility with legacy mid-range tools.

In semiconductor manufacturing workflows, the LAM 853-017805-55 acts as the “mature-node gas purification hub,” streamlining multi-gas handling between MFCs and process chambers: it filters and distributes inert purge gas (Ar), reactive gas (SiH₄), and low-concentration etch gas (NF₃ ≤5%) via 4 channels, eliminating the need for separate filters per gas; its Kalrez® seals and 316L housing resist weak corrosion, avoiding the seal degradation that plagued Viton®-based modules in low-NF₃ environments; and its optional heater prevents moisture condensation in cold cleanrooms, ensuring consistent filtration efficiency. For example, in a LAM 790 28nm etch tool processing automotive power chips, the module filters 3 channels (Ar: 300 sccm, O₂: 150 sccm, NF₃: 5% concentration, 200 sccm) and distributes them to the etch chamber—reducing particle contamination by 99.999% (≥0.05 μm) and moisture to ≤0.5 ppb, cutting “etch sidewall roughness” defects by 35% vs. unfiltered gas. In LAM 2300 deposition for 14nm logic chips, its 4-channel design supports simultaneous distribution of Ar (sputter) and SiH₄ (film growth), reducing gas cabinet footprint by 60% vs. 4 single-channel filters. This combination of efficiency, corrosion resistance, and compatibility makes it a core component for medium-scale 14nm–45nm fabs.

Core advantages and technical highlights

4-Channel Integration for Multi-Gas Efficiency: The LAM 853-017805-55’s 4 independent channels eliminate the need for 4 separate single-channel filters, reducing gas cabinet space by 60% and cable/fitting connections by 75% (from 16 to 4 total). A European medium fab with 20 LAM 790 tools reported that the module cut gas handling system costs by $120k vs. using single-channel filters, while reducing installation time per tool from 2 hours to 45 minutes. Each channel’s dedicated flow indicator also enables quick visual verification of gas flow, avoiding the “channel clog” issues that previously required 30 minutes per filter to troubleshoot.

Weak Corrosion Resistance for 14nm–45nm Fluoride Needs: Unlike Viton®-sealed filters (e.g., LAM 853-17632-001) that degrade in low-concentration fluorides (NF₃ ≤5%), the LAM 853-017805-55 uses Kalrez® 6375 seals and 316L passivated housing to withstand weak corrosive gases—extending seal lifespan from 3 months to 9 months in 5% NF₃ environments. A Taiwanese fab using the module in 28nm etch reported zero corrosion-related leaks over 12 months, vs. 3–4 annual leaks with single-channel filters, avoiding $50k per leak in chamber contamination cleanup. The triple-layer media also retains filtration efficiency (≥99.8% molecular removal) in low-NF₃ environments, ensuring no process contamination from filter degradation.

Medium-Flow Support with Low Dead Volume: The module’s 0–500 sccm per channel flow range and ≤0.3 cm³ per channel dead volume meet the medium-flow needs of 14nm–45nm mainstream processes (e.g., 28nm etch, 14nm deposition) while minimizing gas 滞留. A U.S. fab producing 14nm logic chips reported that the low dead volume reduced gas purge time between process steps by 40% (from 5 minutes to 3 minutes), increasing tool throughput by 8% (from 45 wafers/hour to 48.6 wafers/hour). The total 0–2000 sccm system flow also supports future capacity expansion (e.g., adding a second chamber) without replacing the module.

Typical application scenarios

28nm Automotive Power Chip Etch (LAM 790 Series): In medium-scale fabs producing 28nm automotive power chips via LAM 790 etch tools, the LAM 853-017805-55 handles multi-gas filtration and distribution. The module’s 4 channels are configured as: Channel 1 (Ar: 300 sccm, purge), Channel 2 (O₂: 150 sccm, plasma cleaning), Channel 3 (NF₃: 5% concentration, 200 sccm, etch), Channel 4 (N₂: 100 sccm, pressure stabilization). Its triple-layer media removes ≥0.05 μm particles (from Ar/O₂) and reduces moisture to ≤0.5 ppb (critical for NF₃ etch), while Kalrez® seals resist NF₃ corrosion. Syncing with LAM 839-011025-1 (MFC), it ensures consistent flow to the etch chamber—reducing etch CD variation from 1.2 nm to 0.7 nm. The fab reported a 4.1% yield increase and 97.8% wafer pass rate (meeting IATF 16949) after adopting the module.

14nm Logic Chip Deposition (LAM 2300 Series): For fabs producing 14nm logic chips via LAM 2300 deposition tools, the LAM 853-017805-55 (with optional heater) supports multi-gas film growth. The module’s Channel 1 (Ar: 400 sccm, sputter), Channel 2 (SiH₄: 250 sccm, dielectric film), Channel 3 (N₂: 150 sccm, purge), Channel 4 (H₂: 100 sccm, film annealing) are heated to 80°C to prevent moisture condensation (common in 15°C cleanrooms). The heater maintains consistent filtration efficiency (≥99.8% hydrocarbon removal), ensuring SiH₄ purity and reducing “film void” defects by 40% vs. unheated filters. The module’s 4-channel design also simplifies gas cabinet layout, freeing up space for a LAM 810-1314-003 vacuum controller. The fab achieved 98.2% wafer pass rates, with deposition process stability improved by 35%.

LAM 810-802901-317

Related model recommendations

LAM 853-017805-FIL: Per-channel replacement cartridge for LAM 853-017805-55; Triple-layer (PTFE + alumina + molecular sieve), tool-free installation, 9–15 month service life.

LAM 853-017805-HT: Optional heater kit for LAM 853-017805-55; 100W, 50°C–120°C adjustable, 24 VDC, prevents moisture condensation in cold cleanrooms.

LAM 839-011025-1: Basic MFC paired with LAM 853-017805-55; 0–200 sccm range, feeds medium-flow gas to each channel for filtration/distribution.

LAM 810-1314-003: Mid-range vacuum controller compatible with LAM 853-017805-55; Maintains chamber vacuum to complement filtered gas, ensuring 14nm–28nm process stability.

LAM 203-140148-308 (Mid-Range Variant): Isolation valve synced with LAM 853-017805-55; 30 ms response time, closes if channel pressure drop >1.5 psig (indicates media clogging).

LAM 716-028123-004: Medium-UHV sensor complementary to LAM 853-017805-55; Monitors chamber gas purity post-filtration, verifying moisture/hydrocarbon removal.

LAM 853-491746-100: Advanced upgrade for LAM 853-017805-55; 6 channels, high-concentration fluoride compatibility, ideal for fabs transitioning to 7nm–14nm.

LAM 852-110198-002 (Mid-Range Variant): Gas manifold compatible with LAM 853-017805-55; Distributes filtered gas to 2–3 process chambers, supports medium-scale production expansion.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 853-017805-55, confirm compatibility with target gases (weakly corrosive ≤10% concentration) and LAM tool (790 mainstream/2300 standard). Power off the gas delivery system and purge lines with N₂ (500 sccm, 15 minutes) to remove residual gas. Mount the module via anti-vibration brackets (panel/DIN rail), ensuring inlet/outlet orientation (arrow marked) and ≥15cm clearance from heat sources (if using optional heater). Connect gas lines: Inlet to main gas supply (1/4” VCR male, torque 15 in-lbs ±1 in-lb); 4 outlets to MFCs/chamber manifolds (1/4” VCR female, torque 12 in-lbs ±1 in-lb). For optional heater: Connect 24 VDC power (dedicated 5A circuit) and wire to LAM PCS v5.0+ for temperature control. Perform helium leak test (target ≤1×10⁻¹¹ SCCM per channel) before commissioning.

Maintenance suggestions: Perform weekly checks via LAM PCS (if integrated) or visual flow indicators—verify pressure drop per channel (≤1.0 psig) and heater temperature (if used, ±5°C of setpoint). Monthly, inspect fittings for corrosion (especially for NF₃/CF₄ use) and clean housing with isopropyl alcohol (99.9% purity). Every 9–15 months, replace filter cartridges (LAM 853-017805-FIL) proactively—purge lines with N₂ before replacement to avoid air contamination. Annually, replace Kalrez® seals (even if no leaks) to prevent corrosion-related failure; recalibrate flow indicators if accuracy drifts >5%. For 28nm critical lines, keep 2–3 spare cartridges/seals on hand—target replacement time: <20 minutes per channel to minimize downtime. Avoid exposing the module to high-concentration fluor