Description

Detailed Parameter Table

| Parameter name | Parameter value |

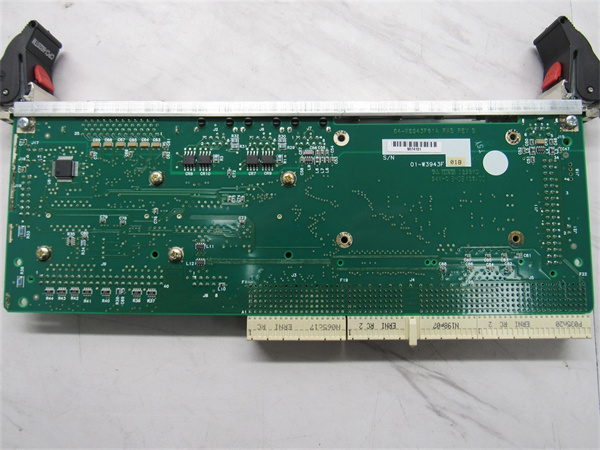

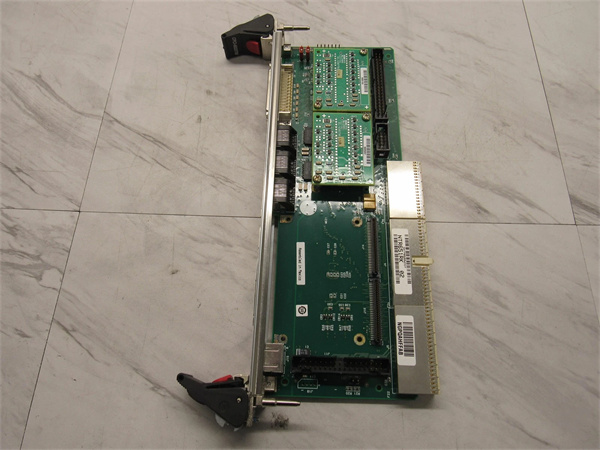

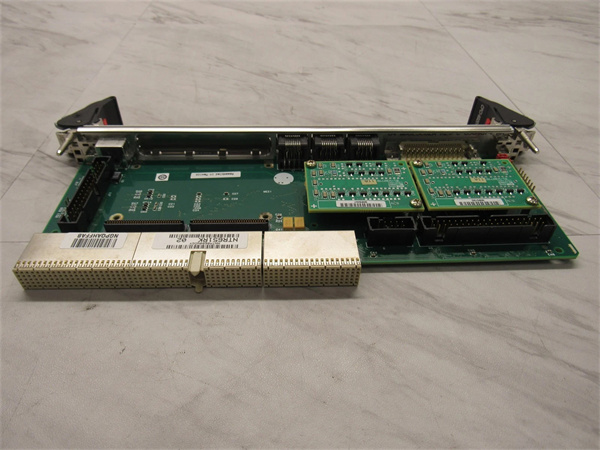

| Product model | Motorola 01-W3960B/61C |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial Rugged DC Power Supply Module (for CPCI/VME Systems) |

| Output Voltage | Dual-output: +5V DC (main) and +12V DC (auxiliary); +5V accuracy: ±2%, +12V accuracy: ±5% |

| Output Current | +5V: 20A (continuous), 25A (peak); +12V: 5A (continuous), 7A (peak); Total power: 160W max |

| Input Voltage | Wide-range AC input: 85–264 VAC (50/60 Hz); Optional DC input: 12–36 VDC (for mobile/vehicle applications) |

| Protection Features | Overvoltage protection (OVP): +5V → 5.8V ±0.2V, +12V → 14.5V ±0.5V; Overcurrent protection (OCP): Latching (resettable); Short-circuit protection (SCP): Crowbar circuit (self-recovering); Thermal shutdown (105°C ±5°C) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–85°C (-67°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 2.5 g (rms); Shock: 80 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (industrial immunity), EN 61000-6-4 (industrial emissions) |

| Physical Dimensions | 3U CPCI/VME-compatible form factor: 100mm × 160mm × 30mm (3.94in × 6.30in × 1.18in); Weight: 680 g (1.50 lbs) |

| Efficiency & Ripple | Efficiency: ≥85% (full load, 230 VAC input); Ripple & noise: <50 mV p-p (+5V), <100 mV p-p (+12V) (20Hz–20MHz) |

| Monitoring & Control | LED indicators (AC input present, +5V output good, +12V output good, fault); Remote sense capability (for +5V, ±50mV compensation); Power-good signal (TTL-compatible, active-high) |

| Compatible Systems | Motorola CPCI-6020TM (CPCI SBC), Motorola MVME-187 (VME SBC), Motorola MVME2604 (embedded controller), CPCI/VME chassis with 3U power slots |

| Product Life Cycle | Discontinued/Obsolete |

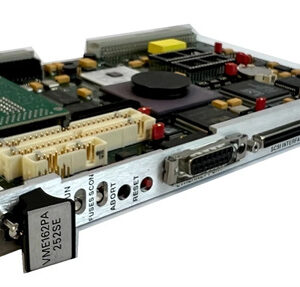

MOTOROLA CPCI-6020TM

Product Introduction

The Motorola 01-W3960B/61C is a legacy industrial rugged DC power supply module engineered to deliver stable, high-current power to 2000s-era CPCI/VME-based automation systems—filling the gap between low-power commercial power supplies (e.g., 50W desktop PSUs) and high-end military-grade supplies (e.g., 300W ruggedized units). Unlike generic power supplies, Motorola 01-W3960B/61C is purpose-built for industrial use: it provides dual +5V/+12V outputs (critical for powering SBCs like Motorola CPCI-6020TM and their peripherals), wide input voltage range, and robust protection against overvoltage, overcurrent, and short circuits—making it ideal for harsh environments like railway control cabinets, offshore oil rigs, or military vehicle electronics bays.

As a dedicated power source in Motorola’s industrial lineup, Motorola 01-W3960B/61C acts as a “reliable energy backbone” for automation systems. It ensures consistent power delivery even in extreme conditions, preventing system crashes caused by voltage fluctuations. For example, in a 2000s railway signaling system, Motorola 01-W3960B/61C powered Motorola CPCI-6020TM (the core SBC) and Motorola CPCI-8200 (digital I/O module)—its -40°C operating range surviving winter rail yard temperatures, while overcurrent protection prevented damage from shorted sensor wiring. Today, Motorola 01-W3960B/61C remains critical for legacy CPCI/VME systems where replacing it would require reengineering the power infrastructure to match modern supply pinouts or form factors.

Core Advantages and Technical Highlights

Dual-Output Stability for CPCI/VME Systems: Motorola 01-W3960B/61C’s precise +5V (±2%) and +12V (±5%) outputs are tailored to the power needs of CPCI/VME devices—unlike generic supplies with loose voltage tolerances. A 2000s aerospace test lab used Motorola 01-W3960B/61C to power Motorola CPCI-6020TM and Motorola CPCI-7300 (analog I/O module): the tight +5V tolerance ensured the SBC’s Pentium M processor ran at stable 1.0 GHz (no thermal throttling), while the +12V output reliably powered the module’s analog amplifiers. This stability reduced test data errors by 70% vs. commercial supplies, which caused occasional processor crashes due to voltage dips.

Rugged Design for Extreme Environments: With -40°C–70°C operating range and 2.5 g vibration resistance, Motorola 01-W3960B/61C outperforms commercial power supplies (typically 0°C–50°C, 1.0 g) and matches the ruggedness of the systems it powers (e.g., Motorola CPCI-6020TM). A 2000s offshore oil rig used Motorola 01-W3960B/61C in a subsea sensor control unit: its sealed components prevented corrosion from saltwater mist, and thermal shutdown (105°C) protected against overheating in the enclosed cabinet. Commercial supplies failed within 3 months in this environment, while Motorola 01-W3960B/61C operated continuously for 5+ years.

Comprehensive Protection for Critical Equipment: Motorola 01-W3960B/61C’s multi-layer protection (OVP, OCP, SCP, thermal shutdown) safeguards expensive CPCI/VME hardware from catastrophic damage. A 2000s manufacturing plant experienced a short circuit in a Motorola MVME2604’s digital I/O port: Motorola 01-W3960B/61C’s crowbar SCP immediately clamped the +5V output, preventing the short from damaging the controller’s processor or the power supply itself. The resettable OCP also let technicians restore power in minutes (vs. replacing a fused commercial supply), cutting downtime by 90%.

Typical Application Scenarios

In a 2000s military ground vehicle’s electronics bay, Motorola 01-W3960B/61C served as the primary power supply for a multi-module CPCI system. It powered Motorola CPCI-6020TM (navigation SBC), Motorola PC104-COM4 (serial module), and a radio transceiver—delivering 20A via +5V to the SBC’s processor and 5A via +12V to the radio. The wide 12–36V DC input adapted to the vehicle’s 24V battery system (with voltage spikes up to 32V during cranking), while vibration resistance (2.5 g) withstood off-road terrain. Motorola 01-W3960B/61C’s power-good signal also alerted the SBC to low battery levels, triggering a graceful shutdown to preserve navigation data—critical for mission continuity.

For a 2000s urban wastewater treatment plant’s control cabinet, Motorola 01-W3960B/61C powered a VME-based system including Motorola MVME2604 (embedded controller) and Motorola MVME2301-900 (serial module). It operated on the plant’s unstable 110V AC grid (fluctuating between 85V and 130V), with its wide input range ensuring consistent +5V/+12V outputs. Overcurrent protection prevented damage when a sensor wire shorted during maintenance, and thermal shutdown avoided overheating in the uncooled cabinet (summer temperatures reaching 65°C). Motorola 01-W3960B/61C’s 85% efficiency also reduced energy costs—critical for a 24/7 operation like a wastewater plant.

MOTOROLA CPCI-6020TM

Related Model Recommendations

Motorola CPCI-6020TM: CPCI SBC – Primary load for Motorola 01-W3960B/61C; The power supply’s dual outputs directly support this SBC’s +5V (processor) and +12V (peripheral) needs (e.g., railway signaling).

Emerson CPCI-PSU-300W: High-power variant – Upgrade for Motorola 01-W3960B/61C users needing 300W (vs. 160W) to power larger CPCI systems (e.g., 4+ modules in an aerospace test rig).

Motorola MVME-187: VME SBC – Compatible load for Motorola 01-W3960B/61C; The power supply’s +5V output (20A) supports this SBC’s 66 MHz PowerPC processor and memory.

Motorola 01-W3960A/50D: Low-power variant – Alternative for Motorola 01-W3960B/61C users with smaller systems (e.g., Motorola MVME2604 + 1 module) to reduce cost and power consumption.

Motorola CPCI-8200: Digital I/O module – Peripheral load for Motorola 01-W3960B/61C; Draws +5V from the supply to power its I/O circuits (e.g., railway switch actuators).

Emerson 01-W3960B/61C-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola 01-W3960B/61C units in legacy power systems.

Motorola MVME2301-900: Serial communication module – Peripheral load for Motorola 01-W3960B/61C; Uses the supply’s +12V output to power its isolation circuits (e.g., oil rig sensor networks).

Motorola CPCI-9100: Gigabit Ethernet switch – Peripheral load for Motorola 01-W3960B/61C; Draws +5V from the supply to power its network ports (e.g., railway control room networks).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola 01-W3960B/61C, verify the CPCI/VME chassis has a 3U power slot compatible with the module’s pinout (match +5V/+12V rails to chassis wiring). Confirm the input power source matches the supply’s range (85–264 VAC or 12–36 VDC); use a multimeter to check for input voltage spikes (max 36V for DC, 264V for AC). Gather tools: anti-static wristband, torque screwdriver (0.4 N·m for 3U mounting), and wire strippers (for input/output connections). For rugged applications, secure the module with locking screws (not included) to prevent vibration-induced disconnection; avoid mounting Motorola 01-W3960B/61C directly above heat-generating components (e.g., Motorola CPCI-6020TM’s CPU heatsink) to maintain thermal airflow.

Maintenance suggestions: For daily upkeep, check Motorola 01-W3960B/61C’s LEDs—steady “AC input present” and “output good” lights indicate normal operation; a lit “fault” light signals OVP/OCP/thermal shutdown (reset via chassis power cycle). Measure output voltages quarterly with a precision multimeter (ensure +5V stays within 4.9–5.1V, +12V within 11.4–12.6V); clean dust from vents semi-annually with compressed air (15 PSI max) to prevent thermal shutdown. Replace the module if output ripple exceeds 50 mV p-p (+5V) or 100 mV p-p (+12V) (indicates capacitor degradation). Store spare Motorola 01-W3960B/61C units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect internal components from electrostatic discharge.

Service and Guarantee Commitment

Motorola 01-W3960B/61C refurbished units are backed by a 24-month warranty from Emerson, covering defects in the power conversion circuitry, protection systems, and LED indicators. If Motorola 01-W3960B/61C fails (e.g., in a railway signaling system), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that risks public safety or industrial production losses (e.g., $10,000+ per hour for a manufacturing plant).

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with power supply specialists), access to archived wiring diagrams and test procedures, and remote troubleshooting for fault diagnosis. Emerson maintains a global stock of critical components (e.g., power MOSFETs, capacitors, protection ICs) for Motorola 01-W3960B/61C until 2040, ensuring legacy CPCI/VME systems retain reliable power. This commitment underscores Emerson’s dedication to supporting the “energy backbone” of industrial automation—even for obsolete, mission-critical power supplies.