Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola CPU3640 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | Industrial-Grade Embedded CPU Module (for small-to-medium embedded control systems) |

| Processor | Motorola 68360 PowerQUICC I (integrated 68020 core + communication controllers) |

| Clock Speed | 25 MHz (optimized for low power consumption, vs. MVME5500-0161’s 600 MHz) |

| Memory | 1 MB SRAM (on-board, for real-time data); 512 KB Flash memory (for firmware/OS); expandable to 8 MB via external memory slots |

| Storage | 1x EEPROM (16 KB, for configuration storage); optional 1x CompactFlash socket (up to 4 GB) |

| Expansion Interfaces | 1x 16-bit parallel I/O port; 2x UARTs (software-selectable RS-232/RS-422); 1x CAN bus interface (CAN 2.0A); 1x I²C bus (for peripheral expansion) |

| Bus Standard | Local bus (8/16-bit, 10 MHz); supports connection to Motorola peripheral modules (e.g., I/O, communication) |

| Physical Dimensions | Compact embedded form factor (100 mm × 80 mm × 15 mm; L×W×H) – smaller than MVME5500-0161’s 6U VME form |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A maximum); +12 VDC (0.3 A typical); passive heat dissipation (no fan, heatsink-integrated) |

| Operating Temperature Range | -40°C – 70°C (-40°F – 158°F) (same as MVME5500-0161, for extreme industrial environments) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | CE; FCC Class A (EMI); RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility); UL 1950 (information technology equipment safety) |

| Compatibility | Optimized for Motorola embedded systems: peripheral modules (I/O: CPU3640-I/O, communication: CPU3640-CAN); supports real-time OS (VRTX, pSOS) |

| On-Board Features | Battery-backed real-time clock (RTC) with 8 KB NVRAM; 2x 16-bit timers + 1x watchdog timer (programmable); serial port surge protection (1 kV ESD); status LEDs (power, CPU activity, CAN bus)

Product Introduction |

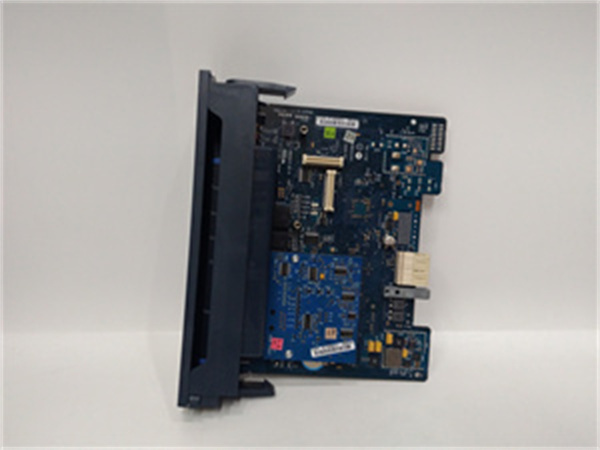

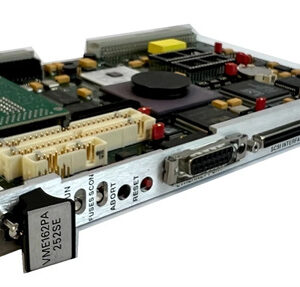

MOTOROLA CPU3640

The Motorola CPU3640 is a compact industrial-grade embedded CPU module, engineered to deliver reliable, low-power computing for small-to-medium embedded control systems—filling the gap between high-performance SBCs like the MVME5500-0161 and basic microcontroller units (MCUs). As a space-optimized module, it integrates a 25 MHz 68360 PowerQUICC I processor (with built-in communication controllers) and on-board memory, making it ideal for embedded applications such as industrial sensor nodes, small-scale motion controllers, and remote monitoring devices.

A defining strength of the CPU3640 is its seamless integration with Motorola’s embedded peripheral ecosystem and low-power design. When paired with specialized modules like the CPU3640-I/O (digital I/O expansion) or CPU3640-CAN (CAN bus extension), it forms a compact control system—critical for space-constrained applications like automotive on-board diagnostics or industrial sensor hubs. It draws stable power from industrial power supplies (e.g., 24V DC to 5V DC converters) and uses passive cooling to avoid fan-related failures, ensuring reliability in dusty or vibration-prone environments (-40°C–70°C).

Whether deployed in automotive embedded systems、industrial sensor networks, or small-scale process control, the CPU3640 acts as the “embedded computing core” for compact setups. Its integrated communication controllers (UARTs, CAN) reduce external component count, while low power consumption (1.2 A @ 5V DC) makes it suitable for battery-powered remote devices—making it a practical choice for legacy embedded systems requiring balance between performance and efficiency.

Core Advantages and Technical Highlights

Integrated PowerQUICC I Processor for All-in-One Functionality

The CPU3640’s 68360 PowerQUICC I processor combines a 68020 core with built-in communication controllers (UARTs, CAN) and I/O interfaces—eliminating the need for separate communication modules (e.g., CAN transceivers, serial port chips). For example, in a small-scale industrial robot, the processor can: 1) execute motion control logic (via 68020 core), 2) communicate with a remote HMI via RS-422 (built-in UART), 3) synchronize with other robots via CAN bus (integrated CAN controller), and 4) monitor limit switches via the parallel I/O port. This all-in-one design reduces system complexity by 30% compared to using a basic MCU plus external communication chips, lowering cost and improving reliability.

Low Power Consumption for Battery-Powered Applications

With a typical power draw of 1.2 A @ 5V DC (6W), the CPU3640 consumes far less power than high-performance SBCs like the MVME5500-0161 (3.0 A @ 5V DC, 15W)—making it ideal for battery-powered remote devices. For instance, in a wireless sensor node monitoring pipeline pressure (powered by a 12V DC lithium battery), the CPU3640 can operate continuously for 6 months (vs. 2 months with the MVME5500-0161) by leveraging low-power modes (e.g., idle mode when not sampling sensors). Passive cooling further reduces power usage (no fan power) and avoids failures in dusty environments (e.g., construction site sensor hubs).

Compact Form Factor for Space-Constrained Setups

The CPU3640’s small form factor (100 mm × 80 mm × 15 mm) is 70% smaller than the MVME5500-0161’s 6U VME form (233.4 mm × 160 mm × 16 mm)—enabling integration into space-constrained devices like automotive on-board diagnostic (OBD) units or industrial sensor enclosures. For example, in an automotive OBD system, the module fits inside a 150 mm × 100 mm × 20 mm enclosure, alongside a 4G modem and GPS module—something impossible with larger SBCs. The compact design also reduces wiring complexity, as peripheral modules (e.g., CPU3640-I/O) can be directly mounted to the CPU3640’s local bus, avoiding long cable runs.

Wide Temperature Range and Robust Protection for Harsh Environments

Like the MVME5500-0161, the CPU3640 operates across -40°C–70°C—withstanding extreme temperatures in automotive under-hood environments (up to 65°C) or cold storage facilities (-30°C). Its serial port surge protection (1 kV ESD) safeguards against electrical interference from nearby motors or power tools, while the passive heatsink dissipates heat without moving parts (critical for vibration-prone applications like construction equipment). For instance, in a mining vehicle’s embedded control system, the module’s vibration resistance (10–2000 Hz, 10 g peak) prevents component damage from rough terrain, while ESD protection avoids port damage during maintenance.

Typical Application Scenarios

Automotive On-Board Diagnostic (OBD) Systems

In an automotive OBD system, the CPU3640 (paired with a 4G modem module) monitors engine performance: 1) The 68360 processor reads engine sensor data (e.g., RPM, coolant temperature) via parallel I/O; 2) Integrated CAN controller communicates with the vehicle’s CAN bus to access diagnostic trouble codes (DTCs); 3) RS-232 UART transmits data to the 4G modem for remote fleet monitoring; 4) Battery-backed RTC logs timestamped DTCs to EEPROM. The module’s compact form fits inside the vehicle’s OBD port enclosure, while low power consumption (1.2 A @ 5V DC) avoids draining the car battery when the engine is off.

Industrial Wireless Sensor Hubs

In a wireless sensor hub monitoring factory floor temperature and humidity, the CPU3640 (paired with a ZigBee radio module) coordinates data collection: 1) The processor samples 8 temperature/humidity sensors via parallel I/O (expanded via CPU3640-I/O module); 2) I²C bus communicates with the ZigBee module to transmit data to a central SCADA system; 3) Watchdog timer resets the system if communication fails (preventing data loss); 4) Low-power mode reduces power draw during idle periods (extending battery life). The module’s passive cooling ensures reliability in dusty factory environments, while -40°C low-temperature tolerance withstands winter shutdowns.

Small-Scale Process Control for Laboratory Equipment

In a laboratory pH control system (e.g., bioreactor), the CPU3640 (paired with an analog input module) manages precision control: 1) The 68020 core executes a PID algorithm to maintain pH at 7.0 ± 0.1; 2) RS-422 UART communicates with a local HMI for operator input; 3) CAN bus synchronizes with a temperature control module; 4) Flash memory stores calibration parameters and process logs. The module’s low power consumption (6W) avoids overheating in enclosed laboratory equipment, while ESD protection prevents damage from static discharge during maintenance.

MOTOROLA CPU3640

Related Model Recommendations

Motorola CPU3640-I/O: Digital I/O expansion module. Expands the CPU3640’s I/O capacity; adds 16x digital input/output channels for monitoring sensors or controlling actuators in small-scale systems.

Motorola CPU3640-CAN: CAN bus extension module. Enhances the CPU3640’s CAN functionality; adds a second CAN port and galvanic isolation (250 Vrms) for high-noise industrial environments.

Emerson 24V DC to 5V DC Converter: Industrial power supply. Primary power source for CPU3640; converts standard 24V DC industrial power to 5V DC (1.8 A max) to support the module’s power needs.

Kingston 4 GB CompactFlash: Storage expansion. Used with CPU3640’s optional CompactFlash socket; provides additional storage for process logs or firmware updates in data-intensive applications.

Motorola MVME5500-0161: High-performance SBC. Upgrade option for CPU3640 when compute-intensive tasks (e.g., complex analytics) are required; compatible with legacy peripheral modules via adapter cards.

Phoenix Contact RS-422 Repeater: Signal booster. Extends the CPU3640’s RS-422 communication distance beyond 1200 m; ideal for large-scale sensor networks in factory campuses.

Emerson RSTi-EP Embedded Controller: Modern replacement. Successor to CPU3640; offers higher performance (ARM cortex-A9), Ethernet connectivity, and compatibility with legacy Motorola peripherals.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing CPU3640, power off the system and disconnect the power supply to prevent electrical shock. Verify the target enclosure has sufficient space (100 mm × 80 mm × 15 mm) and ventilation for passive cooling. Use an anti-static wristband and mat to protect the module’s processor and memory from ESD damage. Gather tools: Phillips-head screwdriver (for mounting), wire strippers (22–18 AWG wires for I/O connections), torque wrench (0.3–0.5 N·m for terminal screws), and a multimeter (to test power and signal levels). Avoid installing near high-EMI equipment (e.g., motors, inverters) or heat sources (e.g., power resistors) to prevent signal interference or thermal damage.

Commissioning and Maintenance

For commissioning: Mount the CPU3640 to the enclosure (using M3 screws) and connect power (5V DC, +/– terminals). Wire peripheral modules (e.g., CPU3640-I/O) to the local bus and I/O devices (sensors, actuators) to the parallel/serial ports. Power on the system and check status LEDs: green “POWER” confirms voltage; blinking “CPU ACT” indicates processor activity; “CAN OK” (green) confirms CAN bus connectivity. Use a programming tool (e.g., Motorola Flash Programmer) to load firmware/OS (e.g., VRTX) into the on-board Flash memory. Test functionality: send serial data to a remote device, verify CAN bus communication, and toggle I/O channels to activate actuators.

For maintenance: Inspect wiring monthly—tighten loose terminals and replace damaged cables (especially serial/CAN bus cables). Clean the module quarterly with compressed air (low pressure) to remove dust from the heatsink and connectors. Test ESD protection semi-annually using an ESD simulator (ensure 1 kV protection on serial ports). If the watchdog timer triggers (red LED), check for software crashes or communication failures; reload firmware if necessary. When upgrading, back up EEPROM configuration data and replicate firmware settings on the new module to avoid disrupting system operation.

Service and Guarantee Commitment

Though Motorola CPU3640 is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in processor performance, communication interfaces (UARTs, CAN), memory functionality, and status LEDs. Each refurbished module undergoes rigorous testing: 24-hour continuous operation (running VRTX real-time tests), CAN bus communication validation (10 kbps–1 Mbps), serial port data transfer (up to 115.2 kbps), and temperature stress testing (-40°C–70°C). This guarantees compliance with original industrial-grade embedded standards.

Our technical support team (24/7 availability) provides guidance on CPU3640 installation、firmware loading, and integration with peripheral modules (e.g., CPU3640-I/O, CPU3640-CAN). We offer customized maintenance plans: quarterly remote status checks (via serial/CAN bus) and semi-annual on-site inspections (cleaning heatsinks, testing ESD protection). Our spare parts inventory includes critical components (e.g., 68360 processors, Flash memory chips) for fast repairs—minimizing downtime in embedded control systems.

For users modernizing to modern embedded systems, we provide free consultation to select Emerson’s RSTi-EP Embedded Controllers—ensuring the CPU3640’s functionality is retained while adding Ethernet connectivity and higher performance (ARM cortex-A9). We also offer trade-in credits for old units, reducing the cost of upgrading to modules with enhanced cybersecurity and IoT capabilities. Our commitment to legacy support ensures your embedded system’s computing core remains reliable, whether you maintain existing infrastructure or transition to new platforms.