Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

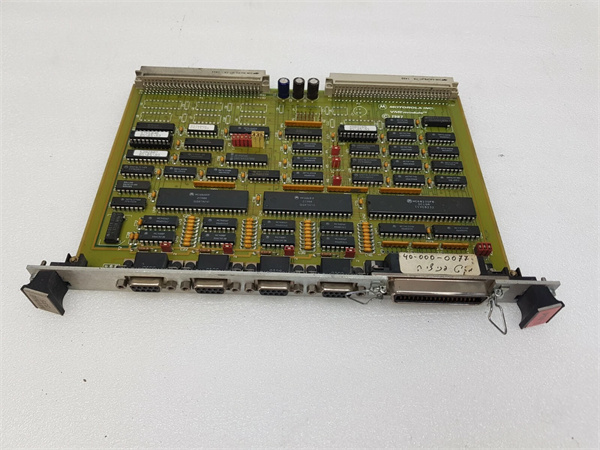

| Product Model | Motorola MVME-204A728-1 |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Specialized Functional Module (analog signal conditioning + isolated digital I/O, tailored for industrial process control) |

| Analog Signal Conditioning | 8x differential analog input channels (signal conditioning: filtering, amplification); input range: ±10 VDC, ±5 VDC, 0–10 VDC (software-selectable); 16-bit ADC resolution; sampling rate: up to 100 kSPS (aggregate) |

| Digital I/O Configuration | 16x isolated digital I/O channels (8 input, 8 output); isolation voltage: 250 Vrms (channel-to-bus); input type: dry contact/TTL; output type: relay (5 A @ 250 VAC/30 VDC) |

| Bus Standard | VMEbus (PICMG VME 1.4 compliant) – 16-bit address/data bus; slave-only mode; supports VMEbus interrupts (level 4–6) |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A maximum); +24 VDC (0.5 A typical, for relay outputs); passive heat dissipation (heatsink-based) |

| Operating Temperature Range | -10°C – 70°C (-14°F – 158°F) (extended industrial environmental tolerance) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 1.4; IEC 61010-1 (measurement equipment safety); FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility) |

| Compatibility | Optimized for Motorola VME SBCs (MVME5500, MVME2434, MVME172-263/260); works with power modules (FAB 0340-1049, 01-W3324F)、communication modules (FLN4234A, MVME712/M)、I/O modules (MVME335, MVME162-223) |

| On-Board Features | Per-channel status LEDs (analog: acquisition active; digital I/O: input state/output relay energized); analog input filtering (50/60 Hz notch filter); digital I/O surge protection (2 kV ESD); EEPROM for configuration storage |

MOTOROLA MVME335

Product Introduction

The Motorola MVME-204A728-1 is a specialized VMEbus functional module, engineered to integrate analog signal conditioning with isolated digital I/O—filling the gap between pure analog modules (e.g., MVME172PA-652SE) and standard digital I/O modules (e.g., MVME162-223). As a 3U VME form factor device, it is designed for industrial process control systems that require both precise analog signal processing (e.g., sensor data conditioning) and robust isolated digital control (e.g., high-voltage actuator activation), eliminating the need for two separate modules and saving critical VME chassis slots.

A defining strength of the MVME-204A728-1 is its seamless integration with the Motorola VME ecosystem. When paired with a host SBC like the MVME5500, it leverages the VMEbus to receive configuration commands (e.g., analog input range, digital I/O direction) and transmit processed data—such as filtered analog sensor readings, isolated digital I/O states, and fault alerts. It draws stable power from modules like the FAB 0340-1049 (for +5 VDC) and 01-W3324F (for +24 VDC relay power), while its -10°C–70°C temperature range expands reliability beyond basic industrial modules—suitable for cold chemical storage facilities or hot refinery control rooms.

Whether deployed in process manufacturing、petrochemical refining, or industrial automation, the MVME-204A728-1 enables streamlined signal management. Its analog input conditioning (filtering, amplification) ensures accurate data capture from noisy industrial sensors, while isolated digital I/O protects the VME system from high-voltage transients—making it a critical component for legacy VME systems requiring both precision and safety in harsh environments.

Core Advantages and Technical Highlights

Integrated Analog Conditioning + Isolated Digital I/O for Process Control

The MVME-204A728-1’s combination of 8x analog signal conditioning channels and 16x isolated digital I/O channels eliminates the need for separate analog conditioning modules and isolated I/O modules—reducing VME chassis slot usage by up to 50%. For example, in a chemical processing plant, the module can: 1) use analog channels to condition and sample pH sensor signals (filtering out pump-induced noise, amplifying weak 0–5 VDC signals), 2) use isolated digital inputs to monitor high-voltage valve position feedback (250 Vrms isolation prevents ground loops), 3) use isolated digital outputs to energize relay-driven chemical dosing pumps (5 A relay capacity handles industrial load). This integrated design simplifies wiring, reduces signal latency between analog and digital control, and lowers overall system cost compared to mixed single-function modules.

Analog Signal Conditioning for Noisy Industrial Environments

The MVME-204A728-1’s analog input channels feature built-in 50/60 Hz notch filters and programmable amplification—critical for accurate data capture in noisy industrial settings. Unlike basic analog modules (e.g., MVME162PA-344E) that directly sample raw signals, this module filters out common-mode noise (e.g., from AC power lines) and amplifies weak sensor signals (e.g., 100 mV from a pressure transducer) to the ADC’s optimal input range (±5 VDC). In a steel mill, for instance, the notch filter eliminates 60 Hz noise from nearby motors, ensuring pH sensor data (critical for water treatment) is accurate to ±0.01 pH units—far better than unfiltered modules’ ±0.1 pH error. The 16-bit ADC further enhances precision, enabling detection of microvolt-level signal changes.

Isolated Digital I/O for High-Voltage Safety

The MVME-204A728-1’s 16x digital I/O channels feature 250 Vrms galvanic isolation (channel-to-bus) and relay outputs (5 A @ 250 VAC/30 VDC)—far more robust than non-isolated modules like the MVME162-223 (no isolation, 20 mA output). This isolation protects the VME system (e.g., MVME5500 SBC, MVME335 communication module) from high-voltage transients caused by industrial equipment (e.g., motor startup, valve actuation). In a petrochemical refinery, for example, the isolated digital inputs safely monitor 240 VAC pump status feedback, while isolated outputs energize 24 VDC emergency shutdown relays—preventing a single high-voltage fault from disabling the entire control system. The 2 kV ESD surge protection on digital channels further safeguards against maintenance-induced static discharge.

Extended Environmental Tolerance for Harsh Conditions

With an operating temperature range of -10°C–70°C, the MVME-204A728-1 operates reliably in extreme industrial environments—from -8°C pharmaceutical cold storage (monitoring temperature via analog channels) to 68°C power plant control rooms (controlling cooling fans via digital outputs). Its passive heatsink design avoids fan-related failures in dusty environments (e.g., cement plants), while the RoHS-compliant housing resists corrosion from chemical vapors (e.g., in fertilizer manufacturing). This durability extends the module’s lifespan, reducing maintenance costs in harsh process control applications.

Typical Application Scenarios

Chemical Processing Plant pH Control

In a chemical mixing process, the MVME-204A728-1 (paired with MVME5500 SBC) manages precision control: 4x analog channels condition and sample pH sensor signals (filtering 50 Hz noise, amplifying 0–5 VDC sensor output to ±10 VDC ADC range), 4x analog channels monitor temperature sensors (0–10 VDC), 8x isolated digital inputs track valve position feedback (24 VDC), and 8x isolated digital outputs energize dosing pump relays (24 VDC, 3 A). The MVME5500 uses the analog data to adjust pump speed via the digital outputs, maintaining pH within ±0.02 units of the target. The module’s isolation protects the SBC from voltage spikes when pumps start, while its temperature tolerance withstands the mixing tank’s 45–65°C ambient heat.

Petrochemical Refinery Emergency Shutdown

In a refinery’s distillation unit, the MVME-204A728-1 (paired with MVME2434 SBC) acts as a safety-critical interface: 8x analog channels sample pressure and temperature sensors (filtering out compressor noise), 8x isolated digital inputs monitor high-voltage (240 VAC) pump status, and 8x isolated digital outputs drive emergency shutdown relays (24 VDC, 5 A). If analog data shows pressure exceeding safe limits, the SBC triggers the digital outputs to close isolation valves and stop pumps—all within 100 ms. The module’s 250 Vrms isolation prevents pump voltage transients from corrupting the SBC’s control logic, while surge protection ensures reliability during lightning storms common in refinery locations.

Food Processing Temperature + Valve Control

In a dairy pasteurization system, the MVME-204A728-1 (paired with MVME172-263/260 SBC) coordinates temperature monitoring and valve control: 6x analog channels sample thermocouple signals (conditioned via amplification, filtered for 60 Hz noise from heaters), 2x analog channels monitor flow rate sensors, 6x isolated digital inputs track valve position (24 VDC), and 10x isolated digital outputs energize heater relays and valve actuators (24 VDC). The SBC uses the analog data to adjust heater power and valve positions, ensuring pasteurization temperature (72°C) is maintained for 15 seconds—meeting FDA standards. The module’s -10°C range withstands the dairy’s cold storage prep area, while isolated I/O protects the system from water ingress-related short circuits.

MOTOROLA MVME335

Related Model Recommendations

Motorola MVME5500: VME SBC. Host controller for MVME-204A728-1; configures analog input ranges/digital I/O, processes conditioned analog data, and executes control logic—critical for leveraging the module’s integrated functionality.

Motorola FAB 0340-1049: Power supply module. Primary power source for MVME-204A728-1’s analog circuits; delivers stable +5 VDC (1.8 A max) to support ADC and signal conditioning components.

Motorola 01-W3324F: Power distribution terminal block. Supplies +24 VDC to MVME-204A728-1’s relay outputs and distributes power to connected digital devices (e.g., valves, pumps).

Motorola FLN4234A: Communication expansion module. Complements MVME-204A728-1 in large systems; transmits the module’s analog/digital data to remote SCADA systems via Ethernet, enabling centralized process monitoring.

Motorola MVME335: Multi-protocol communication module. Works with MVME-204A728-1 to add CAN bus/serial connectivity; transmits process data to legacy HMIs or CAN-based field devices.

Phoenix Contact MINI MCR-SL-C-UI-2UI: Signal conditioner (complementary). Expands the MVME-204A728-1’s analog conditioning capacity; adds 2x additional channels for systems with more than 8 analog sensors.

Emerson RSTi-EP AI/AO Module: Modern Ethernet-based I/O. Replacement for MVME-204A728-1 in systems migrating to Ethernet; offers analog conditioning + isolated digital I/O with Gigabit Ethernet connectivity.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing MVME-204A728-1, power off the VME chassis and disconnect the FAB 0340-1049 (for +5 VDC) and 01-W3324F (for +24 VDC) power supplies to prevent electrical shock. Verify the chassis has an available 3U VME slot and that the VME backplane supports 16-bit slave modules. Use an anti-static wristband and mat to protect the module’s analog ADC and digital isolation components from ESD damage. Gather tools: Phillips-head screwdriver (for chassis mounting), shielded twisted-pair cables (analog inputs, 22–18 AWG), 18–14 AWG wires (digital I/O, for relay loads), torque wrench (0.5–0.8 N·m for terminals), and a precision multimeter (±0.001 V accuracy for analog calibration). Avoid installing near high-voltage equipment (e.g., transformers) or heat sources (e.g., power resistors) to prevent EMI or thermal drift.

Commissioning and Maintenance

For commissioning, insert the MVME-204A728-1 into the VME slot and secure it. Connect analog sensors to the signal conditioning terminals (differential wiring to minimize noise), ensuring correct polarity. Wire isolated digital inputs to field devices (e.g., valve position switches) and digital outputs to relays/actuators, using appropriate wire gauges for load current (e.g., 16 AWG for 5 A relays). Power on the FAB 0340-1049 and 01-W3324F, then check the module’s LEDs: green “POWER” confirms voltage; analog “ACQ” (blinking) indicates active sampling; digital “INPUT HIGH” (green)/“OUTPUT ENERGIZED” (red) confirms state. Use the MVME5500’s configuration software to set analog input ranges (e.g., ±5 VDC for pH sensors), enable notch filters (50/60 Hz), and configure digital I/O direction. Calibrate analog channels using a NIST-traceable voltage source, then test digital I/O by toggling outputs and verifying relay actuation.

For maintenance: Inspect analog/digital wiring monthly—tighten loose terminals, replace damaged shielded cables (to maintain noise immunity), and clean relay contacts (if output load current exceeds 3 A). Clean the module quarterly with compressed air (low pressure) to remove dust from the heatsink and VME connector. Re-calibrate analog channels semi-annually (or after temperature extremes) to correct for ADC drift—use the EEPROM to store calibration coefficients. If an analog channel fails, isolate the issue by testing with a known-good sensor; if a digital output relay sticks, replace the relay module (field-serviceable component). When upgrading, replicate the module’s configuration (analog ranges, filter settings) to avoid disrupting process control.

Service and Guarantee Commitment

Though Motorola MVME-204A728-1 is obsolete, we offer a 90-day warranty on all refurbished units—covering defects in analog signal conditioning, isolated digital I/O functionality, relay outputs, and LED indicators. Each refurbished module undergoes rigorous testing: 24-hour analog data capture (verifying filter performance and 16-bit precision), digital I/O cycling (testing relay contact integrity and isolation resistance), and ESD surge testing (2 kV on digital channels). This guarantees compliance with original industrial-grade process control standards.

Our technical support team (24/7 availability) provides guidance on MVME-204A728-1 installation、analog calibration procedures, and integration with VME SBCs like the MVME5500 or MVME2434. We offer customized maintenance plans: quarterly remote analog data validation (via FLN4234A) and semi-annual on-site inspections (testing isolation resistance, re-calibrating analog channels). Our spare parts inventory includes critical components (e.g., ADC chips, isolation transformers, relay modules) for fast repairs—minimizing downtime in safety-critical process control systems.

For users modernizing to Ethernet-based systems, we provide free consultation to select Emerson’s RSTi-EP AI/AO modules—ensuring the MVME-204A728-1’s analog conditioning and isolated I/O functionality is retained while adding Industry 4.0 connectivity. We also offer trade-in credits for old units, reducing