Description

Detailed Parameter Table

| Parameter name | Parameter value |

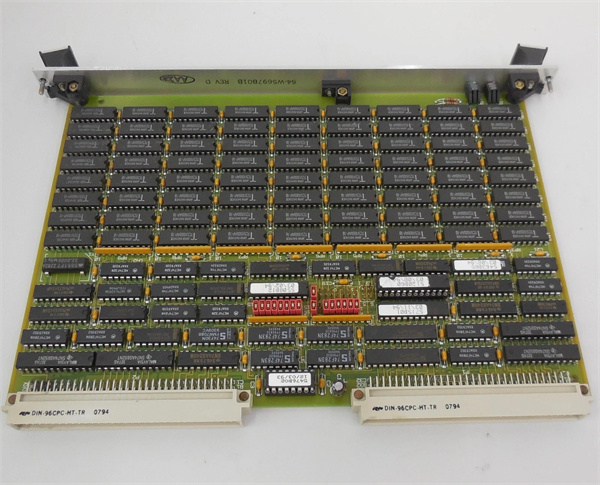

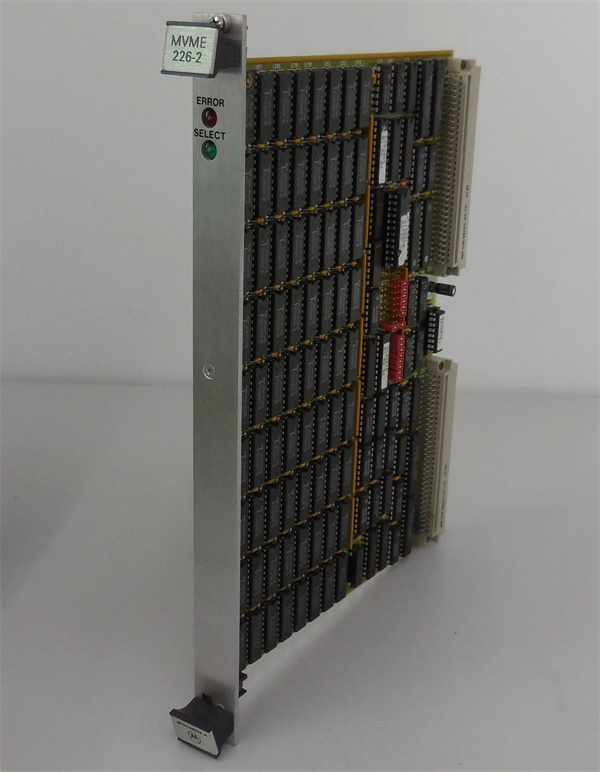

| Product model | Motorola MVME-226-2 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Analog I/O Module (combination of analog input + output) |

| Analog Input (AI) | 8 differential channels; Input range: ±5V DC, ±10V DC (configurable per channel); Resolution: 12-bit; Sampling rate: 100 kSPS (single channel), 12.5 kSPS (all channels) |

| Analog Output (AO) | 4 channels; Output range: ±5V DC, ±10V DC, 0–5V DC, 0–10V DC (configurable); Resolution: 12-bit; Output accuracy: ±0.1% full scale |

| Isolation | Channel-to-channel isolation: 250V AC (rms); Module-to-VMEbus isolation: 500V AC (rms); Transient surge protection: 1 kV (1.2/50 µs) |

| Communication Interface | VMEbus A16/D16 slave interface (complies with IEEE 1014-1987); Interrupt-driven data transfer (configurable interrupt vectors) |

| Environmental Requirements | Operating Temp: -10°C–60°C (14°F–140°F); Storage Temp: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.0 g (rms); Shock: 50 g (peak, 1 ms) |

| Physical Size | 3U VMEbus form factor: 100 mm × 160.0 mm (3.94 in × 6.30 in); Weight: 320 g (0.71 lbs) |

| Power Consumption | Typical: 5 W (25°C, full load); Maximum: 8 W (all AI/AO channels active) |

| Calibration | On-board precision voltage reference (±10V, 0.01% stability); Software-calibratable (no physical potentiometers); Auto-zero correction for AI channels |

| Diagnostic Features | LED indicators (power, AI data ready, AO fault, module status); Built-in over-voltage protection for AO channels; AI channel open-circuit detection |

| Compatible Host SBCs | Motorola MVME-147SB-1, Motorola MVME162-043, Motorola MVME-2700-761-I/O |

Motorola MVME-226-2

Product Introduction

The Motorola MVME-226-2 is a legacy industrial VMEbus analog I/O module designed for high-precision signal acquisition and control, serving as a critical interface between analog sensors/actuators and digital control systems. As a key model in the Motorola MVME 226 series, Motorola MVME-226-2 integrates 8 differential analog input (AI) channels and 4 analog output (AO) channels in a compact 3U form factor—eliminating the need for separate AI and AO modules to reduce VMEbus slot usage.

In automation systems, Motorola MVME-226-2 acts as a “precision analog bridge”: it converts continuous physical signals (e.g., temperature, pressure, flow rate from sensors) into digital data for host SBCs (such as Motorola MVME-2700-761-I/O) and translates digital control commands from the SBC into analog signals to drive actuators (e.g., variable-speed valves, servo motors). This dual-functionality makes Motorola MVME-226-2 ideal for applications requiring both real-time monitoring and closed-loop control—such as chemical process tanks, laboratory test benches, and industrial heating/cooling systems—where analog signal accuracy directly impacts process quality.

Core Advantages and Technical Highlights

High-Precision Analog Signal Handling: Motorola MVME-226-2 delivers 12-bit resolution for both AI and AO channels, with AI sampling rates up to 100 kSPS (single channel) and AO accuracy of ±0.1% full scale. This precision outperforms basic analog modules (e.g., 10-bit resolution) and ensures reliable measurement of subtle signal changes. For example, in a pharmaceutical fermentation tank, Motorola MVME-226-2 can detect 0.1°C temperature fluctuations (via a thermocouple connected to its AI channel) and adjust the heating element’s voltage (via its AO channel) to maintain a stable 37°C—critical for ensuring consistent yeast growth and drug purity.

Flexible Channel Configuration: Each AI channel of Motorola MVME-226-2 supports configurable input ranges (±5V/±10V), while AO channels offer four output ranges (±5V/±10V/0–5V/0–10V)—adapting to diverse sensor/actuator types without hardware modifications. For instance, a water treatment plant can use Motorola MVME-226-2 to monitor pH levels (0–10V input from a pH sensor) and control chemical dosing pumps (4–20 mA output via a signal converter, using the module’s 0–10V AO range). This flexibility reduces inventory costs, as one Motorola MVME-226-2 can replace multiple range-specific modules.

Robust Isolation and Protection: Motorola MVME-226-2 features 250V AC channel-to-channel isolation and 500V AC module-to-VMEbus isolation, preventing ground loops and EMI from disrupting sensitive analog signals or damaging the host SBC. Its AO channels include over-voltage protection (up to 15V), while AI channels detect open circuits—minimizing downtime in harsh environments. In a steel mill, where electrical interference from rolling mills is intense, Motorola MVME-226-2’s isolation ensures accurate measurement of furnace temperature (via a thermistor) and reliable control of cooling water valves—avoiding costly product defects from temperature deviations.

Typical Application Scenarios

In chemical process control, Motorola MVME-226-2 is paired with Motorola MVME162-043 to manage a batch reactor. It connects 6 AI channels to sensors (temperature: ±10V, pressure: 0–5V, pH: 0–10V, and 3 flow rate sensors) and 4 AO channels to actuators (heater: 0–10V, stirrer speed: ±5V, chemical inlet valve: 0–5V, coolant valve: ±10V). The host SBC uses Motorola MVME-226-2’s AI data to run a PID control loop: if reactor temperature exceeds 80°C, the SBC sends a signal to the module’s AO channel to open the coolant valve—maintaining temperature within ±0.5°C. The module’s 12-bit resolution ensures precise chemical dosing, reducing raw material waste by 8% compared to lower-precision modules.

For laboratory material testing, Motorola MVME-226-2 serves as the analog interface for a tensile strength tester. It connects 2 AI channels to load cells (measuring force, ±5V) and displacement sensors (0–10V) and 1 AO channel to a servo motor (controlling test speed, 0–10V). The host SBC (Motorola MVME-147SB-1) logs AI data at 50 kSPS (via the module’s interrupt-driven transfer) to record stress-strain curves, while the AO channel adjusts motor speed to maintain a constant 5 mm/min test rate. Motorola MVME-226-2’s software calibration ensures consistent results across multiple test runs, meeting ASTM standards for material testing accuracy.

Motorola MVME-226-2

Related Model Recommendations

Motorola MVME-226-1: Entry-level variant of Motorola MVME-226-2 with 4 AI/2 AO channels. Suitable for small-scale applications (e.g., single-tank level control) where fewer channels are needed.

Motorola MVME-226-3: High-performance upgrade of Motorola MVME-226-2 with 16 AI/8 AO channels and 16-bit resolution. Ideal for large-scale process plants (e.g., 10+ reactors) requiring more channels and higher precision.

Motorola MVME-2700-761-I/O: Integrated processing + I/O SBC compatible with Motorola MVME-226-2. Provides embedded processing to run control logic using the module’s analog data, eliminating the need for a separate SBC.

Motorola MVME-332: 128-channel digital I/O module. Complements Motorola MVME-226-2 by adding digital control (e.g., on/off valves, status lights) to systems primarily using analog signals.

Motorola MVME-050: Industrial power supply (±5V/±12V, 85–264 VAC). Powers Motorola MVME-226-2 and ensures stable voltage for its precision reference circuit, maintaining measurement accuracy.

Motorola MVME-717: 32-channel digital input module. Works with Motorola MVME-226-2 to monitor discrete signals (e.g., sensor fault status, valve position) in hybrid analog-digital systems.

Emerson MVME-226-2-R: Modernized replacement for Motorola MVME-226-2 (Emerson rebranding) with enhanced EMI protection. Ideal for users upgrading legacy systems while retaining VMEbus compatibility.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-226-2, verify the VMEbus chassis has an available 3U slot and supports A16/D16 addressing. Confirm the power supply provides stable ±5V/±12V (tolerance ±3%)—use a multimeter to avoid voltage fluctuations that could damage the module’s precision reference. Gather tools: anti-static wristband (to protect analog circuitry), torque screwdriver (0.3 N·m for chassis mounting), precision multimeter (for calibration), and a laptop (for software configuration via the host SBC). Ensure analog sensor/actuator cables are shielded (twisted-pair) to reduce EMI—route them separately from power cables to avoid interference.

Maintenance suggestions: For daily upkeep, check Motorola MVME-226-2’s LEDs—steady power, blinking AI data ready, and no AO fault LEDs indicate normal operation. Perform monthly software calibration (via the host SBC) using a precision signal generator to verify AI/AO accuracy—adjust calibration coefficients if deviations exceed ±0.1%. Clean the module’s exterior quarterly with a dry lint-free cloth (avoid compressed air near connectors). If Motorola MVME-226-2 detects an AO fault (red LED), check for over-voltage conditions or short circuits in the actuator cable. Store spare modules in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the on-board voltage reference’s stability.

Service and Guarantee Commitment

Motorola MVME-226-2 is backed by an 18-month warranty from Emerson, covering defects in materials (e.g., precision resistors, isolation transformers) and workmanship. If a fault occurs, Emerson provides free 7-day replacement for in-stock units—critical for applications where analog I/O downtime halts production (e.g., chemical reactors). For extended support, customers can purchase a 30-month service contract, including 24/7 technical support (via phone/email), access to archived calibration guides, and priority repair for complex issues (e.g., isolation circuit failures).

Emerson maintains a global stock of critical components for Motorola MVME-226-2 (precision voltage references, 12-bit ADC/DAC chips) to support legacy users until 2033. Technical engineers specialize in analog I/O systems, offering remote troubleshooting (via VMEbus diagnostic tools) and on-site calibration assistance for high-precision applications (e.g., laboratory testing). This commitment ensures Motorola MVME-226-2 remains a reliable solution for legacy VMEbus systems, helping users avoid costly full-system upgrades while retaining analog control accuracy.