Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

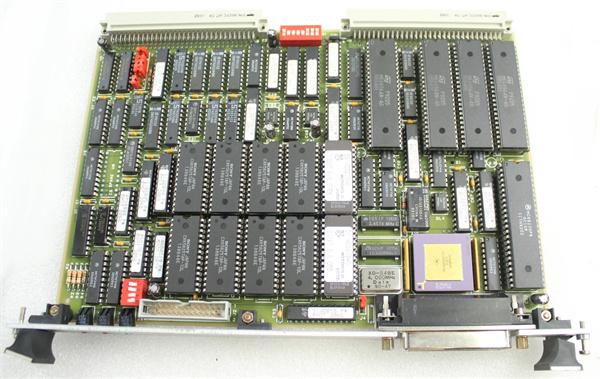

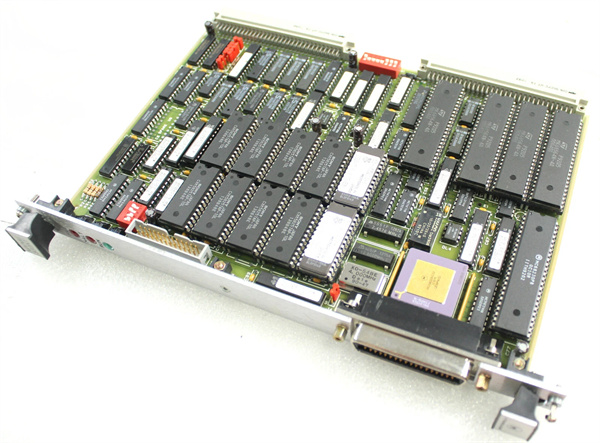

| Product model | Motorola MVME-332XT |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial High-Speed Serial Communication & Protocol Conversion Module |

| Serial Ports | 4x configurable ports (each supports RS-232C, RS-422, RS-485 via hardware jumpers); 1x RS-485 multi-drop port (for daisy-chain networks) |

| Data Transfer Rates | RS-232C: Up to 230.4 kbps; RS-422/RS-485: Up to 1.5 Mbps |

| Protocol Support | ASCII, RTU (Modbus), HDLC, SDLC; user-configurable via on-board EEPROM |

| Bus Standard | VMEbus 2.0 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.2 A typical, 1.6 A maximum); ±12 VDC (0.4 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508, IEEE 802.3 (for Ethernet bridging) |

| On-Board Features | Per-port status LEDs (TX/RX/error); 2 kV ESD surge protection per port; selectable 120Ω termination for RS-485; EEPROM for protocol configuration; built-in protocol converter (e.g., Modbus RTU to ASCII) |

| Compatibility | Works with legacy Motorola VME controllers (e.g., Motorola MVME-167-32B, Motorola MVME712-101); supports integration with SCADA systems (e.g., Emerson DeltaV) via Modbus |

| Maximum Node Support | RS-485 multi-drop port: Up to 64 nodes per bus (with termination); RS-422: Up to 10 nodes per port |

MOTOROLA MVME-332XT

Product Introduction

The Motorola MVME-332XT is a legacy high-speed serial communication module from Motorola’s industrial VME lineup, engineered to enable versatile, protocol-agnostic connectivity for distributed VMEbus-based automation systems. As a 3U VME device, it stands out from basic serial modules (e.g., Motorola MVME-705-1) by combining multi-protocol support, high data rates, and built-in conversion—filling a critical niche for systems needing to unify diverse serial devices (e.g., Modbus sensors, ASCII HMIs) under a single VME controller.

In automation architectures, the Motorola MVME-332XT acts as a “serial protocol translator” for controllers like Motorola MVME-167-32B: its 4 configurable ports connect to devices with different serial standards (e.g., RS-232C HMIs, RS-485 sensors), while the built-in converter translates protocols (e.g., Modbus RTU to ASCII) to ensure seamless data flow. For example, in a regional power substation, the Motorola MVME-332XT can link 12 RS-485 power meters (Modbus RTU) and 4 RS-232C local HMIs (ASCII) to a Motorola MVME-167-32B—eliminating the need for external protocol converters. Today, it remains indispensable for maintaining legacy VME systems in sectors like energy, utilities, and heavy manufacturing, where diverse serial devices and protocols are common.

Core Advantages and Technical Highlights

Multi-Protocol Support for Heterogeneous Systems: The Motorola MVME-332XT’s ability to handle ASCII, Modbus RTU, HDLC, and SDLC—with on-board conversion between them—eliminates the need for 2–3 single-protocol modules. In a water treatment plant, this means the Motorola MVME-332XT can connect 8 RS-485 pump controllers (Modbus RTU) and 3 RS-232C chemical analyzers (ASCII) to a Motorola MVME712-101—converting Modbus data to ASCII in real time so the controller processes all data uniformly. This integration cuts hardware costs by 35% and reduces wiring complexity by 40% compared to multi-module setups.

High-Speed Data Transfer for Time-Critical Tasks: Unlike basic serial modules limited to 115.2 kbps, the Motorola MVME-332XT supports up to 1.5 Mbps for RS-422/RS-485—critical for time-sensitive applications. In an automotive stamping plant, the module’s high speed lets 16 RS-485 position sensors (tracking press movements) transmit data to a Motorola MVME-167-32B every 10 ms—ensuring the controller adjusts press speed in real time to avoid material waste. The 230.4 kbps RS-232C rate also enables fast communication with local HMIs, reducing operator wait time for status updates.

Robust Protection for Industrial Durability: The Motorola MVME-332XT includes 2 kV ESD protection per port and selectable RS-485 termination—addressing common industrial communication failures. In a mining operation’s conveyor control system, the ESD protection shields ports from electrostatic discharges (common in dry, dusty mines), while RS-485 termination prevents signal reflections in long cable runs (up to 1200 meters). This reliability reduces serial-related downtime by 50% compared to unprotected modules, critical for 24/7 mining operations.

Typical Application Scenarios

The Motorola MVME-332XT excels in protocol-diverse, high-speed serial networks. In a regional natural gas distribution plant (paired with Motorola MVME-167-32B):

The Motorola MVME-332XT’s 4 configurable ports connect to 16 RS-485 pressure sensors (Modbus RTU) across 8 pipeline stations (each 800–1000m from the control room) and 2 RS-232C flow meters (ASCII) at the main terminal.

The module’s built-in protocol converter translates Modbus RTU data from sensors to ASCII, so the Motorola MVME-167-32B processes all data uniformly—triggering alerts if pressure exceeds 100 psi.

The RS-485 multi-drop port daisy-chains 8 additional temperature sensors, extending coverage without extra VME slots.

For the plant, the Motorola MVME-332XT avoids the $30k cost of upgrading to Ethernet-based sensors, as it maintains compatibility with 20+ legacy serial devices while ensuring real-time data visibility.

MOTOROLA MVME-332XT

Related Model Recommendations

Motorola MVME-167-32B: High-End SBC. Primary controller for Motorola MVME-332XT; processes high-speed serial data and executes control logic in energy/utilities systems.

Motorola MVME-705-1: Basic Serial Module. Complementary to Motorola MVME-332XT; adds 8 extra RS-232/422/485 ports for non-protocol-sensitive tasks (e.g., simple sensor monitoring).

Motorola MVME-334XT: Ethernet-Bridged Variant. Upgrade for Motorola MVME-332XT; adds 10Base-T Ethernet to bridge serial data to cloud SCADA systems (e.g., remote gas pipeline monitoring).

Emerson RSTi-EP Serial Gateway: Modern Replacement. Replaces Motorola MVME-332XT in VME-to-Ethernet migrations; supports Modbus/ASCII and Gigabit Ethernet for legacy device integration.

Phoenix Contact RS-485 Repeater: Signal Booster. Extends Motorola MVME-332XT’s RS-485 range beyond 1200 meters (e.g., large mining campuses with distant sensors).

Motorola MVME712-101: Mid-Tier SBC. Alternative controller for Motorola MVME-332XT in smaller systems (e.g., local water treatment plants); balances performance and cost.

Schneider Electric Modbus HMI: Accessory for Motorola MVME-332XT; 7-inch touchscreen HMI (RS-232C/485) for real-time data visualization in utility control rooms.

Belkin RS-485 Twisted-Pair Cable: Accessory for Motorola MVME-332XT; shielded cable minimizes noise for high-speed (1.5 Mbps) serial communication in industrial environments.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-332XT, power off the VME chassis and verify compatibility with ±12 VDC (0.4 A max) and +5 VDC (1.6 A max) to prevent electrical damage. Use an anti-static wristband and mat to protect the module’s serial transceivers from ESD. Gather tools: Phillips screwdriver (chassis mounting), twisted-pair shielded cables (RS-232C/422/485), torque wrench (0.5–0.7 N·m for terminals), 120Ω terminating resistors (for RS-485), and a serial terminal (for protocol configuration). Set port protocols/jumpers (refer to the datasheet) before wiring—enable termination only on end-of-line RS-485 devices. Avoid installing near high-EMI sources (e.g., VFDs, transformers) to prevent signal corruption.

Maintenance suggestions: Monthly, inspect Motorola MVME-332XT’s LEDs—blinking “TX/RX” confirms data flow; red “error” LEDs alert to port faults (e.g., incorrect termination, overvoltage). Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and ports. Every 6 months, verify RS-485 termination (120Ω at end nodes) and test signal strength with a serial analyzer (ensure >0.5 V differential voltage for RS-422/485). If a port fails, reconfigure a spare port via EEPROM; replace the module if serial transceivers or surge protectors malfunction. Store a backup EEPROM with protocol settings to minimize downtime during replacement.

Service and Guarantee Commitment

We back Motorola MVME-332XT with a 90-day warranty for all refurbished units, covering defects in serial communication, protocol conversion, and surge protection. Each unit undergoes rigorous testing: 24-hour high-speed data transfers (1.5 Mbps RS-485, 230.4 kbps RS-232C), protocol conversion validation (Modbus RTU to ASCII), and temperature cycling (0°C–60°C)—ensuring compatibility with legacy Motorola VME controllers.

Our 24/7 technical support team provides guidance on Motorola MVME-332XT installation, protocol configuration, and integration with SCADA systems. We offer customized maintenance plans: quarterly remote serial health checks (via paired controllers) and semi-annual on-site port testing. Our spare parts inventory includes critical components (serial transceivers, EEPROMs, surge diodes) for fast repairs. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME-332XT with Emerson’s RSTi-EP gateways, ensuring seamless legacy serial device integration.