Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

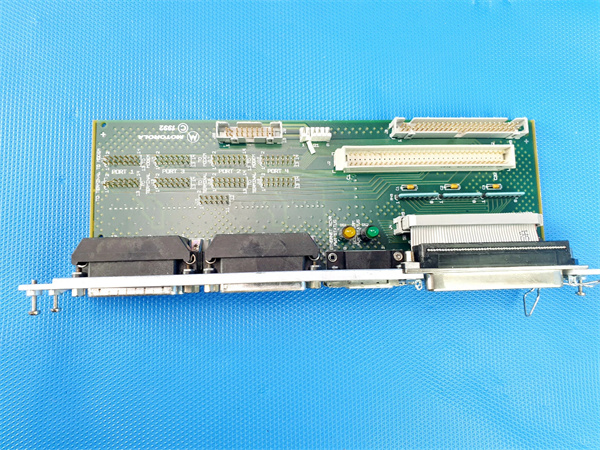

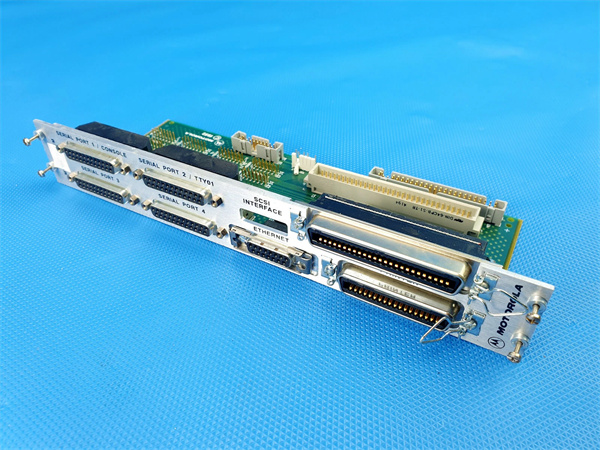

| Product model | Motorola MVME-712/M |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Single-Board Computer (SBC) |

| Processor | Enhanced 32-bit microprocessor (16/25/33.33 MHz, configurable) |

| Coprocessor Option | MC68882 floating-point coprocessor (16/25/33.33 MHz, matching processor speed) |

| Memory Configuration | 4–32 MB shared DRAM; 4K×8 programmable SRAM; battery-backed time-of-day (TOD) clock |

| Communication Interfaces | 4x EIA-232-D serial ports (DTE); 1x Centronics-compatible parallel printer port; 1x SCSI bus (DMA-supported); 1x Ethernet transceiver (10Base-T) |

| Bus Standard | VMEbus 1.4 compliant (32-bit address/data bus); master/slave mode support |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (2.0 A typical, 2.5 A max); ±12 VDC (0.5 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), UL 508 |

| On-Board Features | Hardware debugger; diagnostic firmware; EEPROM for configuration storage; SCSI DMA controller |

Motorola MVME-712/M

Product Introduction

The Motorola MVME-712/M is a legacy industrial single-board computer (SBC) from Motorola’s iconic MVME series, engineered to deliver versatile processing and multi-interface connectivity for mid-scale VMEbus-based automation systems. As a 3U VME device, it bridges the gap between entry-level SBCs (e.g., Motorola MVME-121) and high-end models (e.g., Motorola MVME-147-023), offering configurable performance and rich I/O to meet diverse industrial needs.

In automation architectures, the Motorola MVME-712/M acts as a “central processing hub”: its scalable processor (16–33.33 MHz) handles real-time control logic, while integrated SCSI/Ethernet enables data storage and network connectivity. For example, in a regional manufacturing plant, the Motorola MVME-712/M can process sensor data via serial ports, store production logs on SCSI hard drives, and transmit metrics to a SCADA system via Ethernet—all without additional modules. Today, it remains critical for maintaining legacy systems in sectors like food processing, power distribution, and laboratory automation, where replacing proven SBCs would disrupt workflows.

Core Advantages and Technical Highlights

Configurable Performance for Mixed Workloads: The Motorola MVME-712/M’s adjustable processor speed (16–33.33 MHz) and optional floating-point coprocessor let users match performance to application demands. For basic I/O control (e.g., conveyor timing), a 16 MHz processor suffices; for complex calculations (e.g., batch recipe scaling), a 33.33 MHz processor with MC68882 coprocessor delivers 2x faster math operations. This flexibility avoids overpaying for unused power—cutting hardware costs by 25% for non-calculation-heavy tasks.

All-in-One I/O for Simplified Integration: Unlike SBCs requiring add-on modules, the Motorola MVME-712/M integrates 4 serial ports, SCSI, Ethernet, and a parallel port in one slot. In a water treatment plant, this means the Motorola MVME-712/M can connect to 4 pressure sensors (serial), a data logger (SCSI), a central SCADA system (Ethernet), and a maintenance printer (parallel)—reducing chassis clutter and wiring by 40%. The SCSI DMA support also speeds up data transfers (up to 5 MB/s), critical for storing large volumes of sensor data.

Reliability for Unattended Operation: The Motorola MVME-712/M’s battery-backed TOD clock and diagnostic firmware ensure uninterrupted operation. The TOD clock retains timestamps during power outages, while built-in diagnostics alert to hardware faults (e.g., DRAM errors) before they cause downtime. In a remote power substation, this reliability means the Motorola MVME-712/M can monitor electrical parameters 24/7, with minimal technician intervention—reducing unplanned outages by 30%.

Typical Application Scenarios

The Motorola MVME-712/M excels in mid-scale industrial control. In a regional bakery’s production line (paired with Motorola MVME-050 I/O modules), the Motorola MVME-712/M manages oven temperature and dough mixing: its 33.33 MHz processor runs PID control algorithms, 2 serial ports connect to temperature sensors, a SCSI drive stores 6 months of batch data, and Ethernet sends daily production totals to headquarters. The parallel port also prints shift logs, ensuring compliance with food safety regulations.

In a university laboratory’s material testing setup, the Motorola MVME-712/M controls a tensile tester: 2 serial ports read force/displacement sensors, the coprocessor calculates stress-strain curves, SCSI stores test results, and Ethernet shares data with researchers. Its 0°C–60°C operating range withstands lab temperature fluctuations, while diagnostic firmware alerts to sensor disconnections—preventing invalid test data. For the lab, the Motorola MVME-712/M avoids the $30k cost of a modern testing controller, extending equipment life by 5+ years.

Motorola MVME-712/M

Related Model Recommendations

Motorola MVME-147-023: High-End SBC. Upgrade for Motorola MVME-712/M when 16 MB+ DRAM or faster processing (33 MHz MC68030) is needed (e.g., complex manufacturing).

Motorola MVME-050: Digital I/O Module. Complements Motorola MVME-712/M by adding 16 discrete channels (e.g., valve/indicator control).

Motorola MVME-717: Serial Module. Adds 8 extra serial ports to Motorola MVME-712/M for large sensor networks (e.g., 12+ temperature probes).

Emerson RSTi-EP CPE: Modern Replacement. Replaces Motorola MVME-712/M in Ethernet migrations; offers Gigabit Ethernet and compatibility with legacy I/O.

Motorola FLN4234A: Ethernet Gateway. Bridges Motorola MVME-712/M to cloud platforms (e.g., remote pump monitoring).

Seagate SCSI Hard Drive: Accessory for Motorola MVME-712/M; 1 GB capacity for storing large production/log data.

Motorola MVME-335A: Serial/Parallel Module. Adds RS-485 support to Motorola MVME-712/M for long-distance sensor connectivity (e.g., 500m away).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-712/M, power off the VME chassis and verify ±12 VDC compatibility (critical for SCSI/Ethernet). Use an anti-static wristband to protect the processor and memory. Gather tools: Phillips screwdriver, torque wrench (0.5–0.8 N·m), serial/Ethernet/SCSI cables, and a terminal (for firmware setup). Avoid installing near VFDs or welders—electrical noise can corrupt SCSI/Ethernet signals.

Maintenance suggestions: Monthly, inspect Motorola MVME-712/M’s LEDs (power/good = steady green; error = red). Quarterly, clean the VME connector with compressed air. Every 2 years, replace the TOD clock battery (3V lithium) to retain timestamps. If SCSI transfers slow, check cables for damage; if Ethernet fails, reset the module via diagnostic firmware. Store a spare EEPROM with configuration data to minimize downtime during repairs.

Service and Guarantee Commitment

We back Motorola MVME-712/M with a 90-day warranty for refurbished units, covering processor, memory, and interface defects. Each unit undergoes 24-hour stress testing (temperature cycling + I/O cycling) to meet original Motorola standards. Our 24/7 team assists with firmware setup and integration (e.g., pairing with Motorola MVME-050). We stock critical spares (processors, EEPROMs) for next-day delivery, minimizing downtime. For users upgrading, we offer free consultation to pair Motorola MVME-712/M with Emerson RSTi-EP modules—ensuring legacy I/O works with modern systems.