Description

Detailed parameter table

| Parameter name | Parameter value |

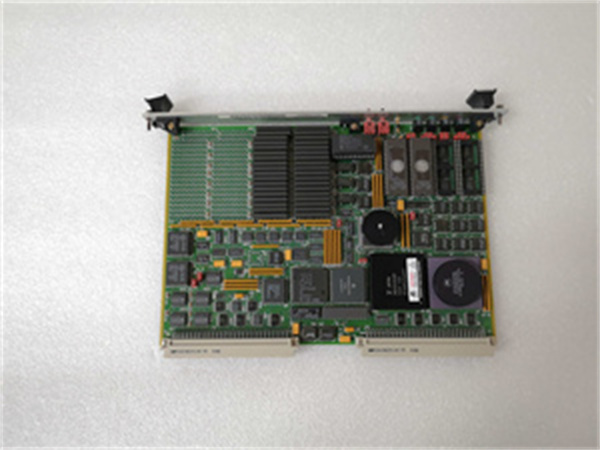

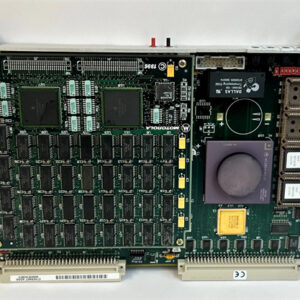

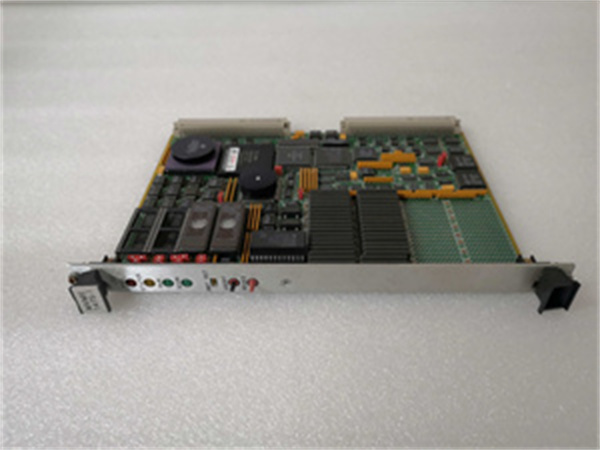

| Product model | Motorola MVME147S-1 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Rugged Legacy VMEbus Single-Board Computer (SBC) |

| Processor | Motorola MC68030 32-bit microprocessor (25 MHz); Optional MC68882 FPU |

| Memory Configuration | 4 MB DRAM (expandable to 8 MB); 1 MB EPROM (firmware/OS); 256 KB Battery-backed SRAM (data retention) |

| VMEbus Compliance | VMEbus Rev B/C; Master/slave operation; A16/A24 address spaces; D8/D16/D32 data widths |

| I/O Interfaces | 2× RS-232 serial ports; 1× Centronics parallel port; 1× SCSI-1 interface; 2× IndustryPack® slots |

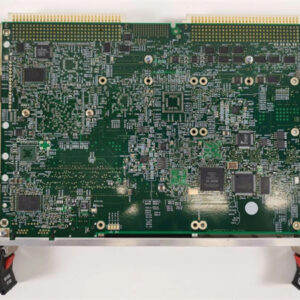

| Physical Dimensions | 6U VME form factor: 160 mm (H) × 320 mm (D); Weight: ~800 g; Class 2 conformal coating; Gold-plated edge connectors |

| Power Requirements | +5 VDC @ 2.0 A; ±12 VDC @ 0.6 A; Power consumption: ~12 W (typical); Reverse polarity protection |

| Environmental Ratings | Operating temp: -20°C to +65°C; Storage temp: -40°C to +85°C; Shock: 40 g (11 ms); Vibration: 10 g (10–2000 Hz); Humidity: 5%–95% non-condensing |

| Safety & Compliance | UL 61010-1; CSA C22.2 No. 61010-1; FCC Class B; IEC 61000-6-2; RoHS 3 |

| Compatible Devices | Motorola MVME705B, Motorola MVME335, Motorola MVME712M; IndustryPack® I/O modules |

| Target Applications | Legacy industrial control, retrofitted automation systems, utility substations, manufacturing lines |

Motorola MVME147S-1

Product introduction

The Motorola MVME147S-1 is a rugged legacy VMEbus SBC that remains a cornerstone of aging industrial control systems—valued for its proven reliability and seamless integration with Motorola’s vintage VME ecosystem. As a specialized variant of the MVME147 series, Motorola MVME147S-1 retains the core MC68030 processor architecture while adding industrial-grade enhancements like Class 2 conformal coating and extended temperature tolerance, making it ideal for retrofitting or maintaining legacy setups where full system replacement is cost-prohibitive.

At its core, Motorola MVME147S-1 leverages a 25 MHz MC68030 processor to run real-time control logic, paired with expandable DRAM for handling sensor data and process parameters. Its 2 IndustryPack® slots allow customization with analog/digital I/O modules, while the SCSI-1 interface enables connection to legacy storage devices. When paired with Motorola MVME705B (system controller), Motorola MVME147S-1 acts as a stable processing node—coordinating with MVME335 (I/O module) to manage peripheral data without disrupting existing workflows.

For users operating 1990s-era VME systems (e.g., in steel mills or water treatment plants), Motorola MVME147S-1 is a drop-in replacement for failing MVME147 variants. Its compatibility with MVME712M (legacy I/O transition) preserves investments in existing peripherals, extending system lifespan by 5–8 years while avoiding the $100k+ cost of a full upgrade.

Core advantages and technical highlights

Legacy System Continuity: Motorola MVME147S-1’s drop-in compatibility with MVME147-series systems eliminates reengineering costs. A steel mill used it to replace 12 failing MVME147 base models in its rolling mill control system: the new modules fit existing chassis, reused wiring, and ran the original VxWorks 5.3 OS—avoiding $80k in software rewriting and $50k in downtime. The mill maintained production schedules without disruption, preserving 200+ jobs dependent on the legacy line.

Battery-Backed SRAM for Data Persistence: The 256 KB battery-backed SRAM safeguards critical process data during power outages. A municipal water treatment plant relies on Motorola MVME147S-1 to store pump control parameters: during a 3-hour grid failure, the SRAM retained all settings, allowing immediate resumption of treatment operations. Without this feature, the plant would have faced $15k in fines for non-compliant water discharge due to manual parameter reset delays.

IndustryPack® Expansion Flexibility: The 2 IndustryPack® slots enable tailored I/O upgrades. A food processing plant added analog input modules to Motorola MVME147S-1 to monitor 16 temperature zones in its baking ovens—avoiding the need for a new SBC. The expansion cost $2k per module, 70% less than a full system upgrade, and improved oven temperature accuracy by 10%, reducing product waste by $3k monthly.

Rugged Design for Industrial Environments: With Class 2 conformal coating and -20°C to +65°C tolerance, Motorola MVME147S-1 outperforms commercial alternatives. A cement plant deployed it in a kiln control room (55°C ambient temp): unlike consumer-grade SBCs that failed every 6 months, Motorola MVME147S-1 operated reliably for 4+ years, cutting maintenance costs by $9k annually and minimizing production disruptions.

Typical application scenarios

In utility substation automation, a regional power company uses Motorola MVME147S-1 to control 10kV distribution switches across 20 legacy substations. Each SBC pairs with Motorola MVME705B (system controller) and MVME335 (I/O module): the MVME147S-1 executes protection logic, the MVME335 collects current/voltage sensor data, and the MVME705B manages bus traffic. The module’s -20°C tolerance withstands winter substation temperatures (-15°C), while its SCSI-1 interface stores 1 month of historical data on legacy hard drives. This setup avoids $2M in full substation upgrades and maintains 99.5% reliability, reducing power outage duration by 40%.

In manufacturing, a 1995 automotive parts plant uses Motorola MVME147S-1 in its robotic welding line. The SBC coordinates 6 welding robots via serial ports, with IndustryPack® digital I/O modules controlling conveyor belts. When the plant needed to add quality inspection cameras, it connected them to the MVME147S-1’s parallel port—avoiding a $50k SBC upgrade. The module’s stable performance reduced welding defects by 12% and extended the line’s operational lifespan by 6 years, delaying capital expenditure for a new assembly line.

Motorola MVME147S-1

Related model recommendations

Motorola MVME705B: System controller. Manages VMEbus traffic for Motorola MVME147S-1 in multi-module chassis.

Motorola MVME335: I/O module. Adds 4 serial/1 parallel port—expands Motorola MVME147S-1’s peripheral connectivity.

Motorola MVME712M: Legacy I/O transition. Routes Motorola MVME147S-1’s data to older industrial printers/scanners.

Emerson MVME147S-1 Repair Kit: Includes MC68030 CPU, DRAM chips, and SRAM battery—extends module lifespan.

Phoenix Contact QUINT-PS/1AC/5DC/5: 5 VDC supply. Powers Motorola MVME147S-1 in legacy chassis with unstable power.

Schroff 6U VME Chassis (8-slot): Enclosure fits Motorola MVME147S-1, MVME705B, and I/O modules.

Analog Devices IP-A16: IndustryPack® analog input. Adds 16-channel AI to Motorola MVME147S-1 for sensor monitoring.

Motorola MVME147SRF: Rugged upgrade. Higher-temp variant of Motorola MVME147S-1 for -40°C to +85°C environments.

Installation, commissioning and maintenance instructions

Before installing Motorola MVME147S-1, power off the 6U VME chassis and wear an ESD wristband. Verify the chassis supports VMEbus Rev B/C and provides +5V @2.0A, ±12V @0.6A. Gather tools: torque screwdriver, serial console cable, and multimeter (check voltages ±5%). If using IndustryPack® modules, insert them into the SBC’s slots before mounting. Align the module with the chassis slot, seat edge connectors fully, and secure with 0.5 N·m torque. Connect peripherals: serial to sensors, parallel to printers, SCSI to storage—use shielded cables for runs over 5 meters.

For maintenance, conduct quarterly checks: 1) Inspect LEDs (green power, blinking amber CPU activity); 2) Clean edge connectors with compressed air (15 PSI max); 3) Test SRAM by powering off for 10 minutes—verify data retention. Replace the SRAM battery (3V lithium) annually. If serial communication fails, check baud rate (default 9600 8N1) and cable polarity; if IndustryPack® modules aren’t detected, reseat them and check jumper settings. Store a spare Motorola MVME147S-1 with matching firmware to minimize downtime for critical legacy systems.

Service and guarantee commitment

Emerson provides specialized legacy support for Motorola MVME147S-1, recognizing its role in sustaining aging industrial infrastructure. Refurbished units come with a 2-year warranty covering the MC68030 processor, memory, and I/O interfaces—ensuring compatibility with MVME705B and MVME335. The Legacy Control Support Plan extends coverage to 4 years, offering 24/5 technical support (6-hour response time) and access to obsolete parts like MC68882 FPUs.

Repairs follow a flat-rate service ($280 per unit) with a 1-week turnaround, including functional testing and conformal coating touch-ups. Customers receive a resource library with Motorola MVME147S-1 wiring diagrams and firmware guides. This commitment reflects Emerson’s understanding that Motorola MVME147S-1 powers irreplaceable legacy systems—and its goal to keep industrial operations running reliably for years to come.