Description

Detailed Parameter Table

| Parameter name | Parameter value |

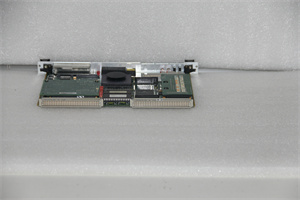

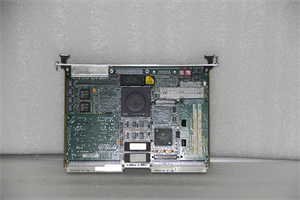

| Product model | Motorola MVME162-220 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Enhanced Entry-Tier Real-Time Single-Board Computer (SBC) |

| Processor | 20 MHz Motorola MC68020 16/32-bit microprocessor; 4 KB L1 cache (2 KB instruction/2 KB data); Basic memory management (no MMU); No FPU |

| Memory Configuration | 2 MB DRAM (non-parity, expandable to 8 MB); 256 KB EPROM (firmware storage); 64 KB battery-backed SRAM (non-volatile, for configuration/data logging) |

| Communication Interfaces | 16-bit VMEbus slave (IEEE 1014-1987 compliant, A16/D16); 2x EIA-232 serial ports (1x console, 1x user-configurable; 9600–57600 bps); No Ethernet |

| Expansion Interfaces | 1x 8-bit parallel I/O port (8 input/8 output, expandable via external modules); 1x RS-485 port (for multi-drop sensor networks) |

| Power Requirements | Input voltage: +5V DC (±5%); Power consumption: Typical 4 W (25°C, no expansion); Maximum 6 W (8 MB DRAM + parallel I/O active) |

| Environmental Ratings | Operating temperature: 0°C–55°C (32°F–131°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 1.2 g (rms); Shock: 35 g (peak, 1 ms) |

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 20mm (3.94in × 6.30in × 0.79in); Weight: 320 g (0.71 lbs) |

| Diagnostic Features | LED indicators (power, CPU activity, VMEbus status, DRAM error, serial port activity); Enhanced power-on self-test (POST, 75% component coverage); Basic fault logging (100+ events) |

| Compatible Peripherals | Motorola MVME-172-513 (entry-level I/O), Motorola MVME340A (serial module), Motorola 01-W3960B/61C (industrial PSU), Motorola MVME300 (GPIB module) |

| Product Life Cycle | Discontinued/Obsolete |

MOTOROLA MVME162-220

Product Introduction

The Motorola MVME162-220 is a legacy industrial VMEbus enhanced entry-tier real-time SBC, designed as an upgrade to Motorola MVME162-210 for 1990s small-to-mid-scale automation tasks. Unlike its predecessor (16 MHz processor, 1 MB max DRAM, 1 serial port), Motorola MVME162-220 boosts processing to 20 MHz, expands memory to 8 MB, adds a second serial port, and includes an RS-485 port—making it ideal for pairing with peripherals like Motorola MVME-172-513 (entry I/O) in applications such as multi-sensor monitoring, small conveyor lines, or regional utility substation control.

As a step-up entry model in Motorola’s MVME162 lineup, Motorola MVME162-220 acts as a “scalable basic control hub.” It handles more complex logic than Motorola MVME162-210 (e.g., “activate pump 2 if pump 1 fails + tank level > 70%”) and connects to multi-drop sensor networks via RS-485. For example, in a 1990s small-scale solar farm, Motorola MVME162-220 used its RS-485 port to monitor 10 solar panel voltage sensors and its parallel I/O to control 4 battery charging relays—its 20 MHz processor ensuring timely adjustments to energy flow. Today, Motorola MVME162-220 remains critical for legacy systems where upgrading to mid-tier SBCs (like Motorola MVME-162PA-252SE) would be overengineered and costly.

Core Advantages and Technical Highlights

Enhanced Processing + Expanded Memory: Motorola MVME162-220’s 20 MHz MC68020 (25% faster than Motorola MVME162-210’s 16 MHz) and 8 MB max DRAM (double the predecessor’s 4 MB) handle more data-intensive tasks. A 1990s food processing plant used Motorola MVME162-220 to control a small packaging line: the faster CPU synchronized 8 conveyor speed sensors and 6 sealing actuators, while expanded DRAM stored 2 weeks of production logs (vs. 1 week with Motorola MVME162-210). This eliminated the need for daily log downloads, saving the plant 2 hours of manual work weekly.

Dual Serial + RS-485 for Flexible Connectivity: Unlike Motorola MVME162-210 (1 serial port, no RS-485), Motorola MVME162-220 adds a user-configurable serial port and RS-485—critical for multi-device networks. A 1990s regional water utility used Motorola MVME162-220 to monitor 12 remote well pressure sensors via RS-485 (1 km distance per sensor): the multi-drop capability reduced wiring costs by 60% vs. running individual cables to each sensor. The second serial port connected to a local HMI, letting operators adjust pressure thresholds without accessing the SBC directly.

Expandable Parallel I/O for Growing Needs: Motorola MVME162-220’s 8×8 parallel I/O (double Motorola MVME162-210’s 4×4) and external expansion support adapt to changing system requirements. A 1990s small electronics assembly shop started with Motorola MVME162-220 controlling 4 component placement actuators—then expanded to 8 actuators by adding an external I/O module (paired via VMEbus). This scalability avoided replacing the entire SBC (a cost savings of $500+ vs. upgrading to a mid-tier model) and let the shop grow production capacity by 100%.

Typical Application Scenarios

In a 1990s small municipal wastewater treatment substation, Motorola MVME162-220 served as the core controller for 2 submersible pumps and 6 water quality sensors. It used its RS-485 port to collect data from pH, turbidity, and flow sensors (1.5 km from the substation) and its parallel I/O to control pump on/off cycles and chemical dosing valves. The 20 MHz processor executed failover logic—if pump 1 tripped, it activated pump 2 within 500 ms to prevent overflow—while battery-backed SRAM preserved sensor data during power outages. Motorola MVME162-220’s 0°C–55°C range withstood the substation’s unheated winter conditions (5°C) and summer heat (50°C), ensuring 99.8% uptime.

For a 1990s retail distribution center’s small conveyor sorting system, Motorola MVME162-220 managed 8 barcode scanners (via RS-485) and 10 sorting gate actuators (via parallel I/O). It read barcode data to route packages to the correct aisle, with the second serial port sending daily throughput logs to a back-office PC. The expanded 8 MB DRAM stored 1 month of scan data, enabling managers to analyze peak sorting times. Motorola MVME162-220’s shock resistance (35 g) also survived occasional package bumps to the control cabinet, avoiding unplanned downtime that would delay order shipments.

MOTOROLA MVME162-220

Related Model Recommendations

Motorola MVME162-210: Entry-tier predecessor – Alternative for Motorola MVME162-220 users with ultra-simple tasks (1 sensor/1 actuator) to reduce costs further.

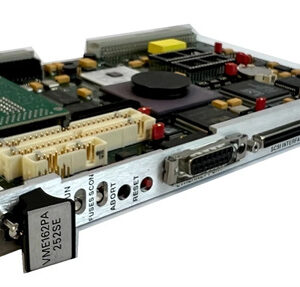

Motorola MVME-162PA-252SE: Mid-tier successor – Upgrade for Motorola MVME162-220 users needing 28 MHz MC68030, Ethernet, and Industry Pack slots (e.g., medium manufacturing lines).

Motorola MVME-172-513: Entry-level I/O – Expands Motorola MVME162-220’s parallel I/O to 24 channels (e.g., adding more pumps/sensors in wastewater systems).

Motorola MVME340A: Serial module – Adds 2 extra RS-232 ports to Motorola MVME162-220 for connecting printers or additional HMIs (e.g., distribution center back-office PCs).

Motorola 01-W3960B/61C: Industrial PSU – Powers Motorola MVME162-220 and peripherals, providing stable +5V DC for reliable operation in harsh environments.

Emerson MVME162-220-R: Refurbished variant – Tested to original specs; Critical replacement for failing Motorola MVME162-220 units in legacy entry systems.

Motorola MVME300: GPIB module – Pairs with Motorola MVME162-220 (via serial port) for integrating test/measurement devices (e.g., lab sensor calibration).

Motorola MVME162-410: Mid-entry SBC – Step-up from Motorola MVME162-220 with 25 MHz MC68030, 8 MB base DRAM, and better VMEbus support (e.g., small HVAC networks).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME162-220, verify the VME chassis supports single-high 3U modules and 16-bit VMEbus (A16/D16). Confirm the power supply (e.g., Motorola 01-W3960B/61C) delivers +5V DC (±5%) with <100 mV ripple—use a multimeter to avoid voltage spikes damaging the MC68020. Gather tools: anti-static wristband, torque screwdriver (0.3 N·m for 3U mounting), and twisted-pair cable for RS-485 (max 1200m). For RS-485 networks, terminate both bus ends with 120Ω resistors to reduce signal reflection; label serial ports to avoid misconfiguring console vs. user ports.

Maintenance suggestions: For daily upkeep, check Motorola MVME162-220’s LEDs—steady power, blinking CPU/serial activity, and no DRAM errors indicate normal operation. Run enhanced POST monthly to validate memory and RS-485; review fault logs quarterly to identify trends (e.g., serial port communication drops). Clean vents every 3 months with compressed air (12 PSI max) to prevent dust buildup. Replace the SRAM battery (3V lithium) annually—failure to do so erases non-volatile data. Store spare Motorola MVME162-220 units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the processor and DRAM.

Service and Guarantee Commitment

Motorola MVME162-220 refurbished units are backed by an 18-month warranty from Emerson, covering defects in the MC68020 processor, serial/RS-485 ports, DRAM, and parallel I/O. If Motorola MVME162-220 fails (e.g., in a wastewater substation), Emerson provides free 10-day replacement—critical for small operations where downtime costs \(1,500–\)4,000 per day.

For extended support, customers can purchase a 24-month service contract, including weekday technical support (via phone/email, with entry-tier SBC specialists), access to archived firmware and RS-485 configuration guides, and remote troubleshooting for POST errors. Emerson maintains a global stock of MC68020 chips, DRAM modules, and serial transceivers for Motorola MVME162-220 until 2035, ensuring legacy enhanced entry-level systems remain operational. This commitment underscores Emerson’s dedication to supporting cost-conscious users with growing automation needs.