Description

Product Introduction

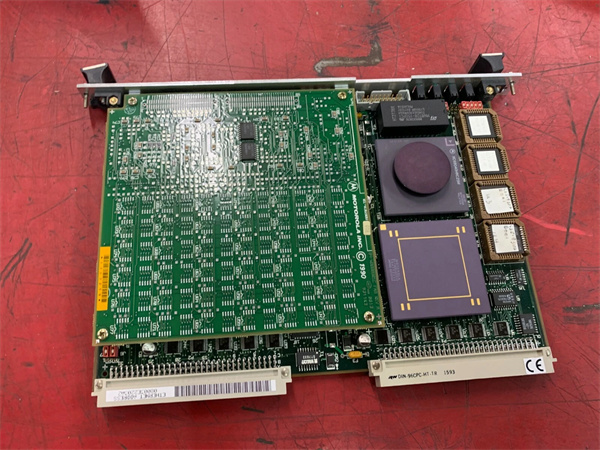

The Motorola MVME167-01A is an industrial VMEbus single – board computer (SBC) that, like its sibling the MVME167 – 01B, is part of Motorola’s (now within Emerson’s industrial automation portfolio) offerings in the industrial computing space. It is designed to meet the demands of industrial applications where reliable computing power and compatibility with VMEbus – based systems are crucial.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | MVME167 – 01A |

| Manufacturer | Motorola (now integrated into Emerson’s industrial automation product portfolio) |

| Product category | Industrial VMEbus Single – Board Computer (SBC) |

| Processor | Motorola MC68040, operating at 25 MHz (32 – bit data/address bus). This processor provides a reliable computing core for industrial applications, capable of handling data processing tasks from multiple sensors in a manufacturing environment, for example, processing data from a dozen or so sensors to control conveyor belt operations. |

| Memory | 4 MB of memory, which is suitable for running industrial control applications of its time. Although expandability might be possible with additional modules, it is not as straightforward as in more modern SBCs. |

| Storage Interface | Equipped with a SCSI interface. This interface allows for the connection of compatible storage devices such as SCSI hard drives. In industrial settings, it can be used to store production data, like in a food and beverage factory, where batch production details, quality control data, and production timestamps can be logged. |

| Communication Interfaces | Features 1x Ethernet port for network communication, likely a basic Ethernet connection that supports common networking protocols like TCP/IP. This enables the SBC to communicate with other devices in an industrial network, such as sending data to a central control station or receiving commands from a supervisory system. There may also be standard serial communication ports, though details are not as elaborately provided. |

| Expansion Slots | Incorporates VMEbus expansion slots. These slots are in line with the VMEbus standard, allowing for the addition of various I/O or functional modules. For instance, analog I/O modules can be added to monitor and control process variables like temperature and pressure in a chemical processing plant, or digital I/O modules can be used to interface with digital sensors and actuators. |

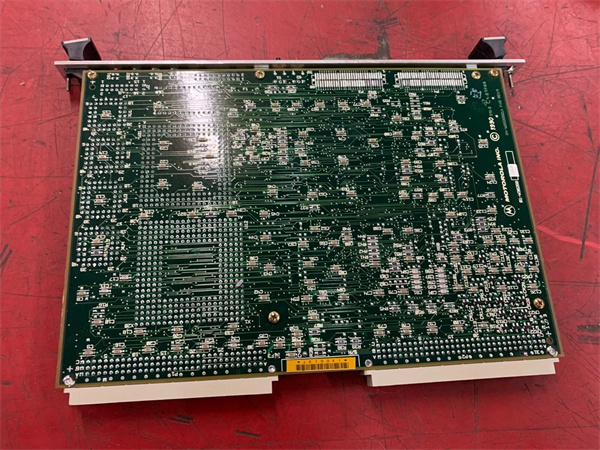

| Bus Compatibility | Complies with the VMEbus standard in a 3U form factor. This ensures seamless integration with VMEbus backplanes and other VMEbus – compatible devices. It can be easily installed into existing VMEbus – based industrial systems, and supports common VMEbus address and data cycles for efficient communication within the system. |

| Environmental Requirements | As a rugged industrial product, it is designed to operate within a temperature range of 0 °C to 55 °C (32 °F to 131 °F) with forced – air cooling. A 100 cfm axial fan can typically provide the necessary cooling velocity. It also has considerations for humidity and vibration resistance, which are essential for withstanding the mechanical stresses and environmental factors present in industrial settings, such as factory floors or industrial control cabinets. |

| Physical Size | Adopts the 3U VMEbus form factor, which is a common and standardized size for industrial single – board computers. This form factor allows for easy installation into standard VMEbus chassis, facilitating integration into existing industrial systems. |

| Installation Method | Mounts onto a VMEbus backplane, following the standard installation method for VMEbus – based single – board computers. This ensures proper electrical and mechanical connection within the VMEbus system, enabling reliable operation. |

| Power Consumption | Specific power consumption details are not provided. However, being a relatively compact and mid – range SBC, it is expected to have a power consumption profile that is suitable for use in industrial control cabinets and systems without excessive power draw, aligning with the capabilities of typical industrial power supplies. |

| Operating System Support | Compatible with a range of industrial operating systems that were prevalent during its time. This includes certain versions of real – time operating systems that were designed to work with Motorola’s hardware platforms, enabling efficient execution of industrial control and monitoring applications. |

| Diagnostic Features | Likely has basic diagnostic capabilities. This may include some form of self – test functionality for the processor and memory to detect hardware faults during startup. LED indicators for power status and basic system health monitoring are also likely present, helping operators quickly assess the operational state of the SBC. For example, a non – lit power LED immediately signals a power supply issue, while a specific pattern of diagnostic LED lights may indicate a memory malfunction. |

Motorola MVME167-01A

Differences from MVME167 – 01B

While the MVME167 – 01A shares many similarities with the MVME167 – 01B, there may be some differences in certain aspects. One of the main differentiators could be in the firmware or software configuration options. The MVME167 – 01A might have a slightly different set of default settings or pre – installed software drivers that are optimized for specific industrial applications or customer requirements. Another possible difference could be in the availability of certain optional features. For example, while both support expansion through VMEbus slots, the MVME167 – 01A might have a different set of recommended or pre – tested expansion modules that are more tailored to a particular industry segment, such as automotive manufacturing or power generation. However, without more detailed documentation, these differences are speculative, and both models are generally very similar in terms of their core hardware capabilities.

Core Advantages and Technical Highlights

Reliable Processor Performance

The Motorola MC68040 processor in the MVME167 – 01A, running at 25 MHz, offers proven computing power for industrial applications of its era. Its 32 – bit architecture enables efficient handling of industrial data types, whether it’s integer – based data from digital sensors or floating – point data from analog sensors. This allows for seamless integration with other industrial components within a VMEbus system, ensuring smooth operation in tasks like controlling the speed of motors based on sensor feedback in a manufacturing line.

SCSI Storage Connectivity

The SCSI interface on the MVME167 – 01A provides a reliable and fast storage connection option. In industrial scenarios, it can be used to attach SCSI hard drives for storing critical process data. For example, in a pharmaceutical manufacturing plant, the SBC can use the SCSI drive to log data related to drug formulation, production batches, and quality control test results. The SCSI interface’s ability to support multiple devices also means that additional storage expansion can be achieved if needed, enhancing the data – logging capabilities of the system.

VMEbus Compatibility

As a VMEbus – based SBC, the MVME167 – 01A benefits from the widespread use and reliability of the VMEbus standard. It can be easily integrated into existing VMEbus chassis and systems. This compatibility allows for the use of a wide range of VMEbus – compatible I/O modules. In a mining operation, for instance, it can be paired with VMEbus – based analog I/O modules to monitor and control environmental parameters such as air quality (measured by gas sensors) and temperature in underground mines. The VMEbus also enables efficient communication between the SBC and other VMEbus – based components, ensuring stable operation within an industrial automation setup.

Basic Diagnostic Tools

The MVME167 – 01A likely comes with basic diagnostic features. Built – in self – test functionality for the processor and memory helps in quickly identifying hardware issues during startup. LED indicators for power status and basic system health provide visual cues to operators. In a large – scale industrial facility, if the power LED is not lit, it immediately signals a power supply problem, while a malfunctioning memory self – test might be indicated by a specific pattern of diagnostic LED lights. This helps in minimizing downtime by allowing for quick identification and resolution of problems.

Typical Application Scenarios

Small – to – Medium – Sized Manufacturing

In a furniture manufacturing factory, the MVME167 – 01A can be used to control the production process. It can connect to various sensors, such as position sensors on automated cutting machines and pressure sensors on wood – pressing equipment, through VMEbus I/O modules. The SBC processes the sensor data to ensure that the production line operates smoothly. For example, if a position sensor indicates that a cutting tool has reached the end of its cut, the SBC can send a signal to the next machine in the line to start its operation. The SCSI storage can be used to log production data, including the number of furniture pieces produced, any errors that occurred during production, and the cycle times of each machine.

Industrial Monitoring in Power Generation

In a wind power generation plant, the MVME167 – 01A can be employed for data acquisition and monitoring. It can connect to sensors measuring parameters such as wind speed, turbine vibration, and generator temperature. Using its Ethernet port, it can transmit the collected data to a central monitoring system for further analysis. The SBC’s ability to handle multiple data streams from different sensors simultaneously makes it suitable for this application. The data logged on the SCSI drive can be used for historical analysis, helping in predicting equipment failures and scheduling maintenance. For example, by analyzing historical vibration data, potential mechanical issues in the wind turbine can be detected before they cause a breakdown.

Legacy System Upgrades

For companies with existing legacy industrial automation systems based on the VMEbus standard, the MVME167 – 01A can be a cost – effective option for upgrades. In a paper mill with an old VMEbus – based control system, replacing a malfunctioning SBC with the MVME167 – 01A can restore system functionality. It can be easily integrated into the existing VMEbus backplane and can communicate with the same I/O modules as the previous SBC. This allows the paper mill to continue using its existing infrastructure while getting the benefits of a new SBC, such as improved diagnostic capabilities and better processor performance for handling the paper production control tasks, like controlling the speed of paper – making machines based on pulp quality sensors.

Motorola MVME167-01A

Related Model Recommendations

Motorola MVME167 – 03B

This is a more advanced variant with a faster processor (133 MHz PowerPC 603e), more memory (32 MB expandable to 64 MB), and enhanced communication interfaces like 10 Base – T Ethernet, 2x RS – 232 serial ports, and 2 – lane Serial RapidIO. It is suitable for applications that require higher processing power and more modern communication options, such as in complex industrial control systems where real – time data transfer and processing of a large number of sensors are needed. For example, in a semiconductor manufacturing plant, where hundreds of sensors are used to monitor and control the wafer fabrication process, the MVME167 – 03B can handle the data load more efficiently than the MVME167 – 01A.

Motorola MVME – 147 – 023

An entry – level VMEbus SBC that can complement the MVME167 – 01A in distributed systems. The MVME – 147 – 023 can handle basic I/O control tasks, such as controlling simple actuators or reading digital inputs from basic sensors. In a large – scale industrial complex, it can work in tandem with the MVME167 – 01A, where the MVME167 – 01A focuses on more complex data processing and communication with higher – level systems. For example, in a large chemical plant, the MVME – 147 – 023 can be used to control the opening and closing of simple valves based on digital sensor inputs, while the MVME167 – 01A processes data from more complex analytical sensors and communicates with the plant’s central control room.

Motorola MVME – 230

A low – profile PMC analog I/O module that can be used with the MVME167 – 01A if there is a need to expand the analog I/O capabilities. In applications where monitoring and controlling analog variables like temperature, pressure, or voltage are required, this module can be added to the SBC’s expansion slots. For example, in a medical equipment manufacturing process where precise control of environmental conditions (such as temperature and humidity) is crucial, the MVME – 230 can be used with the MVME167 – 01A to achieve accurate monitoring and control.

Motorola MVME – 717

A digital input module that pairs well with the MVME167 – 01A. In industrial applications where collecting data from digital sensors or switches is necessary, the MVME – 717 can be connected to the SBC. For instance, in an automotive assembly line, it can collect data from limit switches on robotic arms, which the MVME167 – 01A can then process to control the movement of the robotic arms and ensure proper assembly of car parts.

Motorola MVME – 050

An industrial power supply module that can power the MVME167 – 01A. Ensuring a stable power supply is crucial for the reliable operation of the SBC. In industrial environments where power fluctuations can occur, the MVME – 050 can provide a stable +5V/±12V output, which is essential for the proper functioning of the SBC’s processor and memory, especially in real – time control applications where any power instability could lead to system failures. In a factory with a fluctuating power grid, the MVME – 050 can safeguard the operation of the MVME167 – 01A, preventing data loss and system crashes.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the Motorola MVME167 – 01A, ensure that the VMEbus chassis is compatible with 3U modules and provides the appropriate power supply. Check for correct voltage levels and stability, as deviations can cause damage to the SBC. Gather necessary tools such as an anti – static wristband to protect the sensitive components during handling, a screwdriver for chassis mounting, and an Ethernet cable tester if required to verify network connectivity. Inspect the VMEbus backplane connector for any signs of damage or corrosion and clean it if necessary. If planning to use additional expansion modules, ensure their compatibility with the MVME167 – 01A and the VMEbus system.

Maintenance Suggestions

Regularly check the LED indicators on the MVME167 – 01A to monitor its operational status. A steady power LED indicates proper power supply, while other LEDs may indicate system health, network connectivity, or diagnostic results. Periodically clean the SBC to remove dust, as dust accumulation can lead to overheating and affect performance. In industrial environments, dust can build up quickly, so cleaning every few months is advisable. If possible, perform regular software updates and patches for the operating system and any installed applications to ensure optimal performance and security. Keep a record of any diagnostic error messages or unusual behavior for troubleshooting purposes.

Commissioning Process

After installation, power on the system and perform basic system checks. Check for proper initialization of the processor, memory, and communication interfaces. Use diagnostic tools, if available, to test the functionality of the SBC. Configure the Ethernet settings to enable network communication with other devices in the industrial network. Connect and test any attached storage devices, such as SCSI hard drives, to ensure data can be stored and retrieved correctly. If using expansion modules, verify their functionality by testing the relevant I/O operations. For example, if an analog I/O module is installed, connect it to a known analog sensor and check if the SBC can accurately read the sensor data.

Service and Guarantee Commitment

The Motorola MVME167 – 01A comes with a standard factory warranty, typically covering a period of 12 months. This warranty protects against defects in materials and workmanship. In case of a hardware failure during the warranty period, the manufacturer or authorized service centers will provide repair or replacement services. Technical support is available during normal business hours to assist with installation, configuration, and troubleshooting. For more complex issues, remote diagnostic services may be offered to quickly identify and resolve problems. In addition, spare parts are available for purchase, ensuring that in the event of a component failure outside of the warranty period, the SBC can be repaired in a timely manner. The service and guarantee commitment aims to minimize downtime and ensure the reliable operation of the MVME167 – 01A in industrial applications.