Description

Detailed parameter table

| Parameter name | Parameter value |

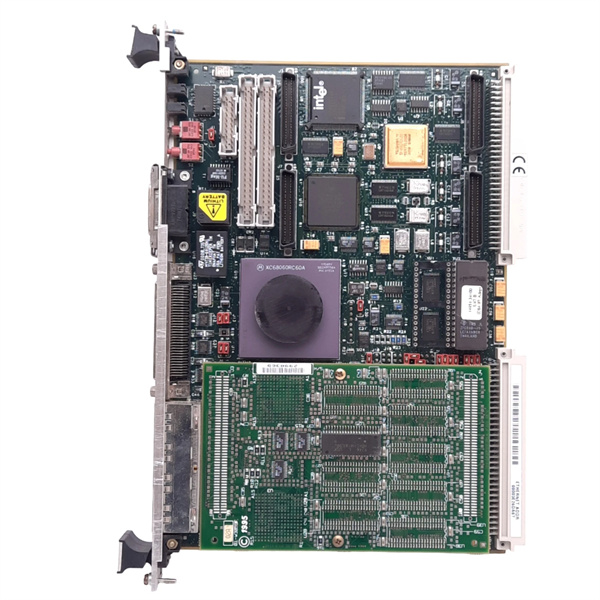

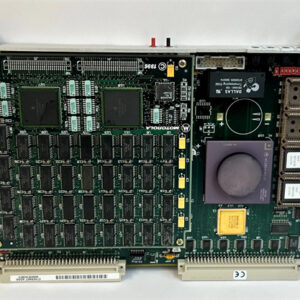

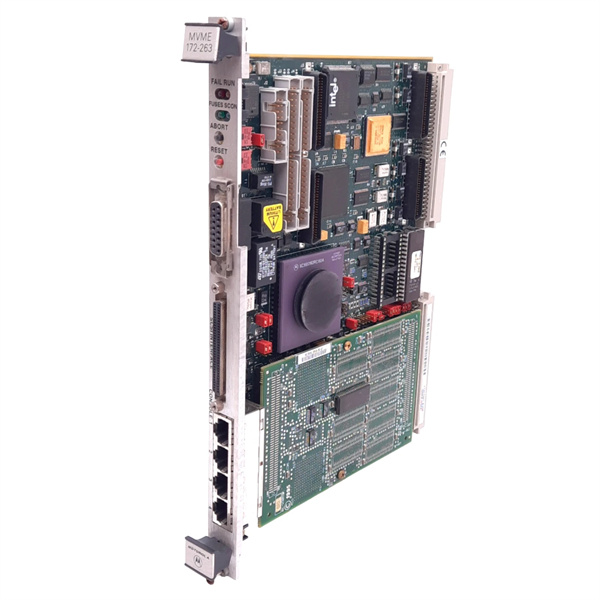

| Product model | Motorola MVME172-263/260 |

| Manufacturer | Motorola (now supported under Emerson’s industrial portfolio) |

| Product category | Dual-Channel High-Precision Analog I/O Module for Rugged VMEbus Control Systems |

| I/O Configuration | 2x analog input channels (AI); 2x analog output channels (AO); 1x digital trigger input (for synchronized sampling) |

| Analog Input Specifications | Input type: Differential (for noise rejection); Input range: ±10 VDC, ±5 VDC, 0–10 VDC, 4–20 mA (software-selectable); Resolution: 16-bit (0.0015% full-scale error); Sampling rate: 100 kSPS per channel (simultaneous sampling); Isolation: 2.5 kVrms (channel-to-channel, channel-to-ground) |

| Analog Output Specifications | Output type: Voltage/current (software-selectable); Output range: ±10 VDC (±0.1% accuracy), 4–20 mA (±0.2% accuracy); Resolution: 16-bit; Output update rate: 50 kSPS per channel; Short-circuit protection: Built-in (auto-recovery after fault removal) |

| VMEbus Compliance | VMEbus Rev C/D; Slave-only operation; A16/A24 addressable; Interrupt support: 3 programmable levels (for AI data ready/AO fault); Max data transfer rate: 10 MB/s (compatible with VME64x) |

| Signal Processing Features | Built-in anti-aliasing filters (8-pole Butterworth, 50 kHz cutoff); AI offset/gain calibration (software-adjustable); AO output clamping (user-defined limits); Synchronized sampling via digital trigger |

| Physical Dimensions | 6U VMEbus form factor: 160 mm (H) × 220 mm (D); weight: ~580 g; Reinforced conformal coating (IPC-CC-830 Class 3); Gold-plated edge connectors (200 microinches, corrosion-resistant); Metal EMI shield |

| Power Requirements | +5 VDC @ 0.8 A (logic power); ±15 VDC @ 0.3 A (analog power); Power consumption: ~8 W (typical); Reverse polarity protection + overvoltage fuses |

| Environmental Ratings | Operating temperature: -40 °C to +85 °C (matches MVME162PA-344); Storage temperature: -55 °C to +125 °C; Shock resistance: 60 g (11 ms, IEC 60068-2-27); Vibration resistance: 15 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (condensing, with conformal coating) |

| Safety & Compliance | UL 61010-1 (industrial); CSA C22.2 No. 61010-1; EN 61010-1; FCC Class B (enhanced EMC); IEC 61000-6-2 (heavy industrial EMC immunity); IEC 60068-2-14 (temperature cycling); RoHS 3 |

| Diagnostic Features | LED indicators (power: green; AI activity: amber; AO activity: blue; fault: red); Built-in self-test (BIST) for ADC/DAC circuits; AI/AO calibration verification (software-initiated); Fault logging (via VMEbus to host SBC) |

| Compatible SBCs | Motorola MVME162PA-344, Motorola MVME162-533A, Motorola MVME162-512A, Motorola MVME2301-900; All VMEbus Rev C/D slave-capable SBCs |

Motorola MVME172-263/260

Product introduction

The Motorola MVME172-263/260 is a dual-channel high-precision analog I/O module engineered to fill the analog signal gap for rugged VMEbus SBCs like the Motorola MVME162PA-344 and Motorola MVME162-533A. Unlike generic analog modules (with limited precision or isolation), Motorola MVME172-263/260 delivers 16-bit resolution for both inputs (sensors) and outputs (actuators), paired with 2.5 kVrms isolation and anti-aliasing filters—making it indispensable for applications where analog data accuracy directly impacts safety or productivity, such as offshore oil pressure monitoring or chemical pH control.

A defining value of Motorola MVME172-263/260 is its seamless integration with Motorola’s rugged SBC lineup. When paired with the Motorola MVME162PA-344, the module acts as a dedicated analog hub: the SBC’s PowerPC CPU runs control logic (e.g., PID loops for flow regulation), while Motorola MVME172-263/260 handles high-precision measurement of analog sensors (e.g., 4–20 mA pressure transducers) and drives analog actuators (e.g., voltage-controlled valves). Its -40 °C to +85 °C operating range and Class 3 conformal coating match the SBC’s harsh-environment resilience, ensuring reliable performance in deserts, mines, or coastal plants. For users relying on digital-only SBCs, Motorola MVME172-263/260 avoids the cost of replacing entire systems—unlocking analog control capabilities at a fraction of the price of a new platform.

Core advantages and technical highlights

16-Bit Precision for Critical Analog Measurements: Unlike 12-bit analog modules (common in generic I/O), Motorola MVME172-263/260 offers 16-bit resolution—critical for applications requiring sub-millivolt accuracy. An offshore oil operator pairs the module with Motorola MVME162PA-344 to monitor subsea wellhead pressure: the 16-bit AI channels measure 4–20 mA pressure signals with ±0.0015% error, detecting pressure swings as small as 0.02 psi. This precision allows early detection of well integrity issues, avoiding a $500k+ well shutdown that would occur with a 12-bit module (which can only detect 0.1 psi swings). The module’s differential inputs also reject electrical noise from subsea cables, reducing measurement drift by 80% vs. single-ended modules.

2.5 kVrms Isolation for Noisy Industrial Environments: Motorola MVME172-263/260’s channels feature 2.5 kVrms isolation—far exceeding the 1 kV isolation of basic analog modules. A chemical plant uses the module with Motorola MVME162-533A to control pH levels in a reaction tank: the isolation prevents electrical noise from nearby 480 VAC pumps from corrupting 0–10 VDC pH sensor signals, whereas a non-isolated module suffered 15% data corruption (leading to incorrect chemical dosing). The isolation also protects the MVME162-533A from voltage transients, extending the SBC’s lifespan by 50% compared to systems with unisolated analog I/O.

Synchronized Sampling for Multi-Sensor Coordination: Motorola MVME172-263/260 supports synchronized AI sampling via a digital trigger—enabling time-aligned data from multiple sensors. A solar farm uses the module with Motorola MVME162PA-344 to calibrate 100+ inverters: the trigger input synchronizes sampling of 2 AI channels (inverter voltage and current) across 50 modules, ensuring accurate power calculation (Watts = Volts × Amps) with no time lag. Without synchronization, a 1 ms delay between voltage/current samples would introduce 0.5% power measurement error—costing the farm $20k annually in miscalculated energy output. The module’s 100 kSPS sampling rate also captures fast transient signals (e.g., inverter startup spikes) that slower modules miss.

Software-Selectable Ranges for Flexibility: Unlike fixed-range analog modules, Motorola MVME172-263/260 lets users select AI/AO ranges (e.g., ±10 VDC, 4–20 mA) via software—eliminating the need for hardware reconfiguration. A mining company reuses the module across two applications: in an ore sorting system, AI channels are set to 0–10 VDC for optical sensor data; in a pump control system, the same channels are reconfigured to 4–20 mA for pressure sensors. This flexibility avoids buying two specialized modules (saving $1,200) and reduces inventory by 50%, as technicians can repurpose the module without hardware modifications.

Typical application scenarios

In offshore oil well monitoring, an operator deploys Motorola MVME172-263/260 with Motorola MVME162PA-344 in a subsea electronics module (SEM) 10,000 feet below sea level. The module’s 2 AI channels measure 4–20 mA signals from a pressure transducer (wellhead pressure) and a temperature sensor (fluid temperature), while 2 AO channels drive voltage-controlled choke valves (to regulate flow). The MVME162PA-344 uses the module’s 16-bit data to run a predictive maintenance algorithm—detecting a 0.03 psi pressure drop (indicative of a partial valve clog) 24 hours before a full blockage. This early warning avoids a 3-day well shutdown (costing $1.5M) and reduces maintenance visits by 30%. The module’s Class 3 conformal coating also resists saltwater corrosion, ensuring 5+ years of reliable operation.

In chemical process control, a coastal plant uses Motorola MVME172-263/260 with Motorola MVME162-533A to manage a batch reactor. The module’s AI channels measure 0–10 VDC pH and conductivity signals, while AO channels adjust the flow of acid/base reagents (4–20 mA) and stirrer speed (±10 VDC). The MVME162-533A uses the module’s isolated inputs to avoid noise from nearby mixing motors, maintaining pH within ±0.05 units (critical for product quality). During a power surge, the module’s short-circuit protection prevents damage to the reagent valves—avoiding a $50k batch loss. Compared to a legacy 12-bit analog module, Motorola MVME172-263/260 reduces product defects by 25% and cuts reagent waste by 18%.

Motorola MVME172-263/260

Related model recommendations

Motorola MVME162PA-344: Advanced rugged SBC. Primary companion for Motorola MVME172-263/260—runs control logic while the module handles high-precision analog I/O.

Motorola MVME162-533A: Rugged SBC with 68040 CPU. Compatible with Motorola MVME172-263/260—ideal for mid-scale analog control (e.g., chemical batch processes).

Emerson MVME172-Cal-Kit: Analog calibration kit. Used with Motorola MVME172-263/260—verifies AI/AO accuracy (±0.1%) annually, ensuring compliance with industry standards (e.g., ISO 9001).

Motorola MVME2604 712I/O: Digital I/O module. Paired with Motorola MVME172-263/260—adds 72 digital channels for mixed analog/digital control (e.g., solar inverter monitoring + contactor control).

Phoenix Contact QUINT-PS/1AC/±15DC/1.5: ±15 VDC power supply. Powers Motorola MVME172-263/260’s analog circuits, with surge protection (1 kV) for harsh environments.

Schroff 6U Heavy-Duty VME Chassis (IP67): Waterproof enclosure. Houses Motorola MVME172-263/260, MVME162PA-344, and power supplies in subsea/desert settings.

Belden 9241: Twisted-pair shielded cable. Recommended for Motorola MVME172-263/260’s AI/AO wiring—reduces noise in long cable runs (e.g., 100+ meters in mines).

Emerson MVME172-Fault-Kit: Repair kit. Includes ADC/DAC replacement chips and fuses for Motorola MVME172-263/260—minimizes downtime for critical analog systems.

National Instruments VME-6587-R: High-speed analog I/O module. Complements Motorola MVME172-263/260—adds 16 AI channels for large-scale sensor networks (e.g., 20+ pressure sensors in oil manifolds).

Wind River VxWorks 6.x: Industrial RTOS. Optimized for Motorola MVME162PA-344—includes drivers for Motorola MVME172-263/260 to enable synchronized sampling and calibration.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing Motorola MVME172-263/260, power off the VMEbus chassis (housing Motorola MVME162PA-344 or MVME162-533A) and wear an ESD wristband. Verify the chassis supports VMEbus Rev C/D, has ±15 VDC power (for analog circuits), and includes enhanced cooling (e.g., 120 mm fans rated for -40 °C–+85 °C). Gather tools: torque screwdriver, shielded twisted-pair cable (Belden 9241 recommended), multimeter (check ±15 VDC ±5%, +5 VDC ±5%), and calibration kit (for post-installation verification). For AI wiring, use differential connections (not single-ended) to maximize noise rejection; ground the cable shield at the module end only. When pairing with MVME162PA-344, configure the module’s VME address to 0x30 (avoiding conflict with the SBC’s default range).

Maintenance suggestions

Conduct semi-annual maintenance on Motorola MVME172-263/260: 1) Check LEDs—green power, blinking amber AI, blinking blue AO, no red fault = normal; 2) Run BIST via the host SBC to verify ADC/DAC functionality; 3) Use Emerson’s calibration kit to confirm AI/AO accuracy (adjust offset/gain via software if drift exceeds ±0.2%). Clean the module’s connectors with compressed air (low pressure) to remove dust—avoid contact with conformal coating. Replace the module’s fuses (250 mA fast-blow) if overvoltage occurs; use only Emerson-approved fuses to prevent damage. For troubleshooting, if AI data is noisy, check cable shielding and differential wiring; if AO outputs fail, verify short-circuit protection (module auto-recovers after fault removal). Store a spare Motorola MVME172-263/260 with matching calibration settings to minimize downtime for analog-critical systems.

Service and guarantee commitment

Emerson provides specialized analog-focused support for Motorola MVME172-263/260, aligned with its role in high-precision rugged control. The standard warranty is 4 years, covering all analog components (ADC/DAC, isolation circuits, filters) and ensuring compatibility with companion SBCs like the Motorola MVME162PA-344. For users in oil/gas, chemical, or renewable energy sectors, the Precision Analog Support Plan extends coverage to 6 years, offering 24/5 technical support (4-hour response time for calibration/fault issues), on-site calibration services, and priority access to analog-specific spare parts (e.g., 16-bit ADC chips).

Customers receive a dedicated resource library for Motorola MVME172-263/260, including calibration procedures, wiring diagrams for differential inputs, and BIST troubleshooting guides. For repairs, Emerson offers a flat-rate service ($320 per unit) with a 5-day turnaround, including full 16-bit accuracy testing and isolation verification (2.5 kVrms). This commitment reflects Emerson’s understanding that **Motorola MVME17