Description

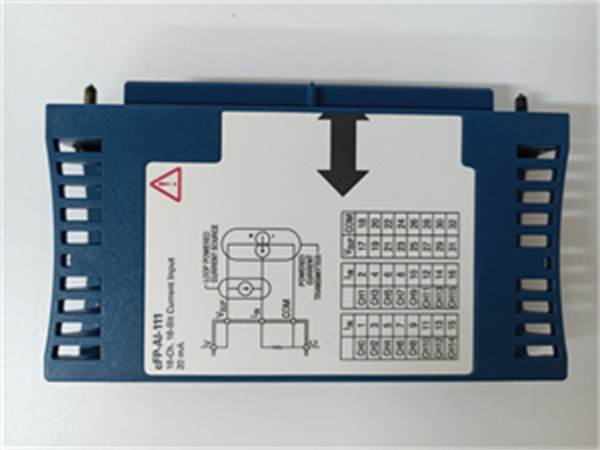

NI CFP – AI – 111 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | CFP – AI – 111 |

| Manufacturer | National Instruments |

| Product category | Compact FieldPoint analog current input module |

| Channels | 16 single – ended analog current input channels |

| Resolution | 16 – bit |

| Input ranges | ±20 mA, 0 – 20 mA, 4 – 20 mA |

| Input impedance | 100 Ω |

| Filter settings | 50 Hz, 60 Hz, 500 Hz |

| Update rate | 3 Hz – 0.83 Hz |

| Overvoltage protection | 2300 Vrms transient overvoltage protection |

| Overcurrent protection | ±30 mA integrated overcurrent protection |

| Over – ranging feature | Can measure 5% beyond each range’s nominal value |

| Filter type | Comb filters with 95 dB rejection at fundamental frequency and at least 60 dB rejection at harmonics |

| Status indicators | LEDs for power, readiness, and out – of – range conditions (details may vary) |

| Physical dimensions | 4.3 x 4.3 x 3.6 inches (109.22 x 109.22 x 91.44 mm) |

| Weight | 4.8 oz (136.08 g) |

| Operating temperature | – 40 °C to 70 °C |

| Storage temperature | – 55 °C to 85 °C |

| Relative humidity | 10 – 90% non – condensing |

| Operating vibrations (random/sinusoidal) | 5 grms / 5 g (10 Hz – 500 Hz) |

| Compliance standards | Meets relevant industry standards for electrical safety and electromagnetic compatibility |

NI CFP-AI-111

Product introduction

The National Instruments CFP – AI – 111 is a high – performance 16 – channel analog current input module, specifically engineered for Compact FieldPoint systems. It serves as a critical interface for accurately measuring and digitizing milliamp – level current signals from a wide variety of sensors and transducers. This makes it an indispensable component in industrial monitoring, control, and data acquisition applications where precise current measurements are required.

As part of NI’s Compact FieldPoint family, the CFP – AI – 111 combines ruggedness, reliability, and flexibility. Its 16 – bit resolution ensures highly accurate conversion of analog current signals into digital values, enabling detailed analysis of the measured data. The module offers three distinct input ranges, allowing it to handle different signal levels, and comes with three filter settings to manage noise and interference, making it suitable for use in both clean and noisy industrial environments. With built – in over – ranging capabilities, on – board diagnostics, and hot – swapping functionality, the CFP – AI – 111 simplifies system integration, operation, and maintenance.

Core advantages and technical highlights

High – resolution current measurement

The NI CFP – AI – 111‘s 16 – bit resolution sets it apart in accurately measuring current signals. This high resolution allows for the detection of even the smallest changes in current, which is crucial in applications such as precision sensor monitoring, where minute variations in current can indicate changes in physical parameters like temperature, pressure, or flow rate. Whether measuring the low – level currents from a thermocouple amplifier or the higher currents from a motor – driven sensor, the CFP – AI – 111 provides detailed and accurate data.

Multiple input ranges and filter options

With three selectable input ranges (±20 mA, 0 – 20 mA, 4 – 20 mA), the CFP – AI – 111 can interface with a diverse range of current – outputting sensors. This flexibility eliminates the need for external range – changing circuitry in many cases, reducing system complexity and cost. Additionally, the three filter settings (50 Hz, 60 Hz, 500 Hz) are designed to combat different types of electrical noise. For example, in power – intensive industrial settings with 50 Hz or 60 Hz mains – related interference, the appropriate filter can be selected to notch out this noise, ensuring clean and accurate signal acquisition.

Over – ranging and protection features

The over – ranging feature of the CFP – AI – 111 allows it to measure up to 5% beyond the nominal value of each input range. This is extremely useful in situations where there may be momentary surges or unexpected signal levels, as it provides a buffer against potential measurement errors. The module also comes equipped with 2300 Vrms transient overvoltage protection and ±30 mA integrated overcurrent protection. These protective features safeguard the module from electrical faults in the connected sensors or the surrounding electrical environment, ensuring long – term reliability and reducing the risk of damage.

Hot swapping and on – board diagnostics

Similar to some of its counterparts in the Compact FieldPoint family, the CFP – AI – 111 supports hot swapping. This means that the module can be inserted or removed from a powered Compact FieldPoint system without disrupting the operation of other connected devices. In industrial settings where continuous operation is critical, this feature enables quick module replacement or addition during system maintenance or expansion. The on – board diagnostics continuously monitor the module’s health, checking for issues such as over – voltage, over – current, or communication problems. This proactive approach to fault detection helps in minimizing system downtime and simplifies maintenance procedures.

Typical application scenarios

In industrial process control, the NI CFP – AI – 111 is extensively used for monitoring the operation of various equipment. For instance, in a manufacturing plant, it can measure the current consumed by motors driving conveyor belts, pumps, or robotic arms. By accurately measuring the current, operators can detect early signs of motor overloading, bearing wear, or other mechanical issues. In a chemical processing plant, it can monitor the current output from sensors measuring the flow rate of chemical substances. The real – time data acquired by the CFP – AI – 111 can be used to adjust control valves, regulate pump speeds, or trigger alarms in case of abnormal operating conditions.

In environmental monitoring, the module plays a crucial role. For example, in a wastewater treatment facility, it can measure the current output from sensors that detect the concentration of pollutants in the water. The CFP – AI – 111’s ability to handle different input ranges and filter out electrical noise makes it suitable for use in such harsh and electrically noisy environments. In air quality monitoring stations, it can measure the current from sensors that detect the presence of harmful gases or particulate matter. The data collected is used to assess environmental conditions and ensure compliance with environmental regulations.

In energy management systems, the CFP – AI – 111 is used to monitor power consumption and generation. In a building’s electrical distribution system, it can measure the current in different circuits to calculate the power usage of various appliances and equipment. This data can be used to optimize energy consumption, identify energy – inefficient devices, and implement energy – saving measures. In renewable energy applications, such as solar or wind farms, it can monitor the current output from solar panels or wind turbines. By accurately measuring the current, operators can assess the performance of the energy – generation equipment, detect faults, and optimize energy production.

NI CFP-AI-111

Related model recommendations

CFP – AO – 100: An 8 – channel analog output module from NI. While the CFP – AI – 111 is focused on analog current input, the CFP – AO – 100 can be paired with it in systems where both input and output of analog signals are required. For example, in a closed – loop control system, the CFP – AI – 111 can measure the current from sensors, and the CFP – AO – 100 can generate analog voltage or current signals to control actuators based on the measured data.

CFP – DI – 100: A 16 – channel digital input module. In industrial applications where both analog and digital signals need to be monitored, this module can work in tandem with the CFP – AI – 111. For instance, in a manufacturing process, the CFP – AI – 111 can measure analog current signals from sensors, while the CFP – DI – 100 can monitor digital signals from switches, relays, or digital sensors.

Compact FieldPoint Chassis: Appropriate Compact FieldPoint chassis, like the CFP – 2020, are necessary to house the CFP – AI – 111 and other compatible modules. The chassis provides power, communication interfaces, and mechanical support, enabling seamless integration into a complete Compact FieldPoint system.

LabVIEW: NI’s LabVIEW software is a powerful tool for programming and controlling the CFP – AI – 111. It offers a graphical programming environment with pre – built functions for data acquisition, signal processing, and device control. LabVIEW simplifies the development of applications that utilize the CFP – AI – 111, allowing engineers to quickly create custom monitoring and control systems.

NI – DAQmx: This driver software is essential for communicating with the CFP – AI – 111. It provides a standardized interface for configuring the module, acquiring data, and handling errors. NI – DAQmx is compatible with various programming languages, including C, C++, and Python, giving developers flexibility in choosing the programming environment for their applications.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI CFP – AI – 111, ensure that the Compact FieldPoint system is powered off. Use an anti – static wristband to handle the module to prevent electrostatic discharge damage, which could potentially harm the sensitive electronics. Verify that the Compact FieldPoint chassis has an available slot that is compatible with the CFP – AI – 111. Connect the appropriate cables to the module’s input terminals, making sure that the wiring is correct for the selected input range. Since the module has single – ended input channels, take care to connect the sensors’ positive and negative terminals correctly. Mount the module in the chassis and secure it using the provided hardware. After installation, power on the Compact FieldPoint system.

Commissioning

Install the NI – DAQmx driver software on the host computer that is connected to the Compact FieldPoint system. Use the NI – MAX (Measurement & Automation Explorer) utility to configure the CFP – AI – 111. Set the input ranges for each channel according to the signals to be measured. Select the appropriate filter settings based on the electrical environment where the module will be operating. Calibrate the module using NI’s calibration utility to ensure accurate current measurements. This calibration may involve applying known current signals and verifying that the module’s output values match the expected values. Test the module by connecting it to actual sensors and monitoring the data acquired by the host system. If using LabVIEW, create a simple data acquisition VI (Virtual Instrument) to start collecting and displaying data from the CFP – AI – 111.

Maintenance suggestions

Regularly inspect the module’s connectors for any signs of corrosion, loose connections, or physical damage. Corrosion can affect the electrical conductivity and lead to inaccurate measurements. If any issues are detected, clean the connectors using a suitable contact cleaner. Monitor the status LEDs on the module. The LEDs should indicate normal power, readiness, and any out – of – range conditions. If the out – of – range LED is constantly on or blinking, check the input signals and the module configuration to ensure that the measured currents are within the selected ranges. Calibrate the CFP – AI – 111 periodically, following NI’s recommended calibration intervals, to maintain measurement accuracy. In case of a suspected module failure, use the on – board diagnostics and NI – MAX to troubleshoot the issue. If the problem persists, contact NI’s technical support for further assistance.

Service and guarantee commitment

The NI CFP – AI – 111 typically comes with a standard warranty, which covers defects in materials and workmanship for a specified period, usually 1 – 3 years depending on the region and purchase terms. NI’s global technical support team is available to provide assistance for installation, configuration, and troubleshooting. They can be reached via phone, email, or online support forums. NI also offers calibration services, either on – site or at their accredited calibration facilities, to ensure that the module continues to meet its specified accuracy requirements. For customers with complex or custom applications, NI’s professional services team can provide consulting, system integration, and software development services to optimize the use of the CFP – AI – 111 in their specific systems.