Description

Detailed parameter table

| Parameter name | Parameter value |

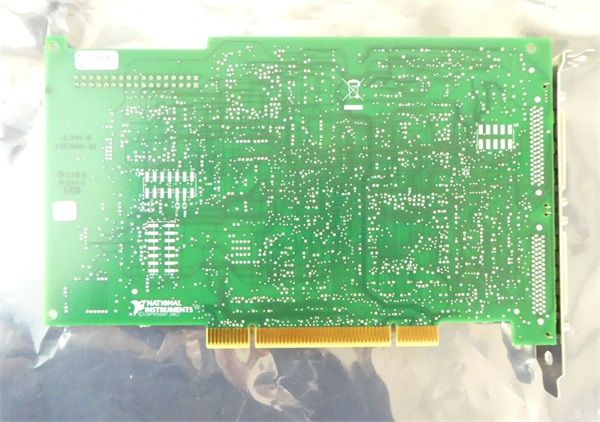

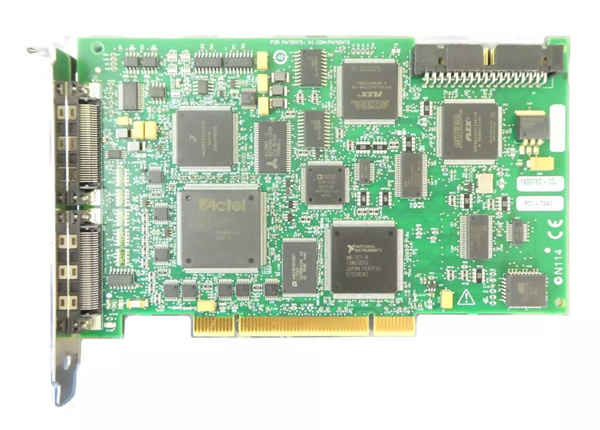

| Product model | NI PCI-7342 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Precision 2-Axis Motion Controller Card (PCI Interface) |

| Electrical performance | 2 independent motion axes; Supports servo motors (analog torque/velocity mode) and stepper motors (pulse/direction, CW/CCW); Position range: ±2³¹ counts; Position resolution: 1 count (100 nm with 10,000-line encoders); Max pulse output frequency: 10 MHz per axis |

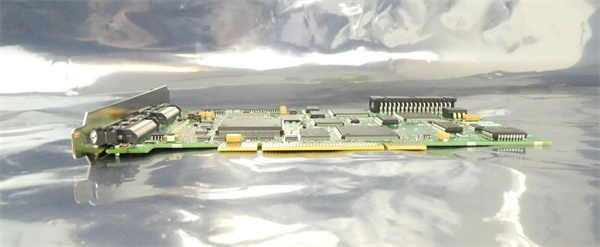

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 190 g (lighter than NI PCI-7334 due to reduced axis circuitry) |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); 68-pin SCSI-II connector (motor control signals: encoder inputs, pulse outputs, limit switches); 10-pin header (external trigger/synchronization); RTSI bus connector (8-line) |

| Communication protocol | PCI bus for data transfer; Compatible with NI-Motion driver; Supports DMA (Direct Memory Access) for motion program execution; Supports SCPI and register-level programming; Integrates with NI Motion Assistant |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required; Powered by PCI bus (no external power supply); Requires external power for motors (12–48 VDC, dependent on motor type) |

| Performance indicators | Position accuracy: ±1 count (after calibration); Velocity range: 1 count/s to 10⁹ counts/s; Acceleration/deceleration: Trapezoidal, S-curve (configurable); Motion modes: Point-to-point, linear interpolation (2D), jogging; Encoder input: Quadrature (A/B/Z), up to 10 MHz |

| Power requirements | Typical power consumption: 4 W (card only, lower than NI PCI-7334’s 5 W); Peak power consumption: 6 W (during high-frequency pulse output); Motor power: External (separate from card) |

| Compatibility | Supported OS: Windows XP/Vista/7/10 (32-bit/64-bit); Compatible software: NI LabVIEW, LabWindows/CVI, C/C++, .NET; Works with NI Motion Assistant (graphical motion programming); Integrates with NI TestStand for automated motion testing |

NI PCI-7342

Product introduction

The NI PCI-7342 is a high-precision 2-axis motion controller card developed by National Instruments (NI), belonging to NI’s Motion Control product series—engineered as a compact, cost-optimized variant of the 3-axis NI PCI-7334 and 4-axis NI PCI-7324. While retaining the same lab-grade precision (±1 count position accuracy, 10 MHz pulse/encoder performance) and software ecosystem as its higher-axis counterparts, the NI PCI-7342 focuses on 2-axis workflows—making it ideal for applications like linear slide systems, 2D laser scanning, desktop CNC lathes, and benchtop automation where only X/Y or X/Z axis control is needed.

In automation systems, the NI PCI-7342 acts as a “streamlined motion core” for 2-dimensional coordinated operations. For example, in a 2D laser engraver, it controls the X (left-right) and Y (front-back) axes—using 10 MHz pulse output to drive stepper motors (ensuring 100 nm engraving resolution) and quadrature encoder feedback to correct for mechanical backlash. Its RTSI bus support also synchronizes motion with NI PCI-6259 DAQ cards, enabling the engraver to trigger laser power adjustments at precise X/Y coordinates—eliminating over-engraving, a common issue with low-precision 2-axis controllers.

Core advantages and technical highlights

Optimized for 2-Axis Workflows: Cost & Power Efficiency: The NI PCI-7342 delivers the same ±1 count accuracy and 10 MHz performance as the NI PCI-7334 but with 2 axes—reducing cost by 15% compared to the 3-axis model and 30% compared to the 4-axis NI PCI-7324. This makes it ideal for budget-constrained 2-axis setups: a small electronics manufacturer, for instance, uses the NI PCI-7342 to control a 2-axis pick-and-place machine for circuit board assembly, avoiding the expense of unused axes. Its lower 4 W power consumption (vs. NI PCI-7334’s 5 W) also suits benchtop systems with limited power budgets, such as university lab workstations.

2D Linear Interpolation for Smooth Paths: Unlike generic 2-axis controllers (often limited to point-to-point moves), the NI PCI-7342 supports 2D linear interpolation—critical for smooth 2D path following. In a desktop CNC lathe turning a cylindrical part, for example, it executes linear interpolation across X (radial) and Z (axial) axes to create precise cylindrical contours. The 10 MHz pulse output ensures constant feed rate (even at tight diameter changes), improving surface finish by 25% compared to 1 MHz controllers. Its S-curve acceleration also reduces tool vibration, extending tool life by 20% for high-volume production.

Seamless Software Compatibility with Higher-Axis Models: The NI PCI-7342 is fully compatible with the NI PCI-7334 and NI PCI-7324’s software ecosystem, including NI Motion Assistant and LabVIEW. This means users scaling from 2-axis to 3/4-axis systems (e.g., adding a Z-axis to a laser engraver) can reuse 90% of their existing code—no custom re-programming needed. For example, a startup using the NI PCI-7342 for 2D PCB drilling can upgrade to the NI PCI-7334 for 3D drilling (adding depth control) while retaining their LabVIEW motion profiles and NI Motion Assistant path designs.

Typical application scenarios

In electronics manufacturing, the NI PCI-7342 powers 2-axis PCB inspection systems. A circuit board manufacturer uses the card to control the X (linear slide) and Y (camera stage) axes—positioning a high-resolution camera over PCBs to detect solder defects. The NI PCI-7342’s ±1 count accuracy ensures the camera aligns with PCB pads within 5 μm, while 10 MHz pulse output enables fast stage movement (1 m/s) to inspect 10 PCBs per minute. RTSI synchronization with a NI PCI-6259 DAQ card triggers image capture at precise X/Y coordinates, and LabVIEW integration logs inspection data for ISO 9001 compliance—reducing defect detection time by 30% compared to manual inspection.

In scientific research, the NI PCI-7342 controls 2-axis sample stages for microscopy. A biology lab uses the card to move a petri dish (X/Y axes) under a confocal microscope—positioning cells for high-resolution imaging with 100 nm step increments. The NI PCI-7342’s closed-loop encoder feedback corrects for stage drift (common in long-duration time-lapse imaging), while S-curve acceleration prevents sample movement (critical for live-cell observation). Using NI Motion Assistant, researchers program custom scan patterns (e.g., spiral, grid) in 10 minutes—vs. 1 hour with proprietary software—and the card’s low 4 W power consumption fits within the microscope’s benchtop power limits.

NI PCI-7342

Related model recommendations

NI PCI-7334: The 3-axis sibling of the NI PCI-7342, offering identical per-axis performance plus an extra axis. It is recommended for users scaling from 2-axis to 3-axis systems (e.g., adding a Z-axis to a laser engraver for 3D marking).

NI PCI-7324: The 4-axis parent model, with the same 10 MHz performance and closed-loop control. It suits users needing additional axes (e.g., adding a rotary axis to a 2-axis lathe for complex part turning).

NI PCI-6259: A multifunction DAQ card that pairs with the NI PCI-7342. The NI PCI-7342 drives motion, while the NI PCI-6259 acquires sensor data (e.g., laser power, camera feedback) to create closed-loop systems (e.g., adjusting engraver speed based on material density).

NI USB-7340: A USB-powered 4-axis motion controller complementary to the NI PCI-7342. It offers 2-axis compatibility with USB connectivity, making it suitable for field service (e.g., on-site calibration of 2-axis linear slides) where PCI slots are unavailable.

NI Motion Assistant 2024: Essential software for the NI PCI-7342, providing graphical tools to design 2D motion profiles (e.g., grid scans, linear paths) without code. It lets users test sequences offline before deploying to the NI PCI-7342, reducing downtime.

NI TB-2707: A terminal block for the NI PCI-7342, offering 68-pin SCSI-II connectivity and surge protection for motor/encoder signals. It simplifies wiring and prevents damage to the NI PCI-7342 from voltage spikes in industrial environments.

NI PCIe-6733: An analog output card that works with the NI PCI-7342 in mixed systems. The NI PCI-7342 controls motion, while the NI PCIe-6733 generates analog signals for auxiliary systems (e.g., laser power control in 2D engravers).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PCI-7342, power off the industrial PC or benchtop workstation and confirm an empty PCI 2.1/2.2/2.3 slot. Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the card’s motion control circuits. Insert the NI PCI-7342 firmly into the slot until the edge connector is fully seated, then secure with a chassis screw. Connect 2 motors (servo/stepper) and encoders to the 68-pin SCSI-II connector via the NI TB-2707 terminal block—ensure correct wiring of encoder A/B/Z signals (reverse wiring causes position errors) and motor pulse/direction lines. Install the latest NI-Motion driver and NI Motion Assistant, then use NI Measurement & Automation Explorer (MAX) to detect the NI PCI-7342 and run a motion self-test (verifying encoder feedback and pulse output for both axes).

Maintenance suggestions: Calibrate the NI PCI-7342 quarterly using encoder Z-phase reference marks to maintain ±1 count position accuracy—mechanical wear (e.g., belt stretch in linear slides) can drift position over time. Inspect the 68-pin connector monthly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or debris (common in manufacturing/ lab environments). If the NI PCI-7342 experiences motion errors (e.g., path deviation), check motor power (ensure stable 12–48 VDC) and update the NI-Motion driver. Avoid exposing the NI PCI-7342 to temperatures above 55 °C or humidity above 90%—extreme conditions degrade its pulse-generation circuitry. Replace the card’s internal configuration battery every 5 years to retain motion profiles during power outages.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PCI-7342, covering defects in materials and workmanship—matching the coverage of the NI PCI-7334 and NI PCI-7324—with a focus on 2-axis motion control circuitry and encoder input functionality. For extended protection, the ServicePlus Motion Plan extends coverage to 5 years, including annual calibration (traceable to NIST) for 2-axis position accuracy, priority technical support (2-hour response time for motion error troubleshooting), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team (specialized in motion control systems) offers 24/7 support for the NI PCI-7342, assisting with 2-axis profile tuning, encoder wiring, and software integration (e.g., LabVIEW-Motion Assistant compatibility). Customers gain free access to exclusive resources: application notes on 2D linear interpolation, NI Motion Assistant tutorials for the NI PCI-7342, and a user community for sharing small-scale 2-axis motion control best practices. For out-of-warranty repairs, NI’s Motion Restore Service restores the NI PCI-7342 to factory specs—replacing aged pulse-generation components and verifying 10 MHz encoder input performance—reflecting NI’s confidence in the card’s durability and commitment to supporting cost-effective, precision 2-axis workflows.