Description

1. Detailed Parameter Table

**

| Parameter Name | Parameter Value |

| Product Model | PXI – 6052E |

| Manufacturer | National Instruments (NI) |

| Product Category | 16 – Channel, 16 – bit Multifunction DAQ Device |

| Input Channels | 16 single – ended or 8 differential analog input channels (software – selectable per channel) |

| Input Ranges | 15 types, including ± 10 V, ± 5 V, ± 2.5 V, ± 1 V, ± 0.5 V, ± 0.25 V, ± 0.1 V, ± 0.05 V, 0 – 10 V, 0 – 5 V, 0 – 2 V, 0 – 1 V, 0 – 0.5 V, 0 – 0.2 V, and 0 – 0.1 V |

| Resolution | 16 – bit |

| Maximum Sampling Rate | 333 ks per second |

| Output Channels | 2 analog output channels |

| Digital I/O Lines | 8 digital I/O lines |

| Counter/Timers | Two 24 – bit, 20 MHz counter/timers |

| Triggering | Analog and digital triggering; 6 trigger lines with 1 star trigger |

| DMA Channels | 3 DMA channels in scatter – gather mode |

| Input Impedance | 10 kΩ for external input of analog or digital trigger (PFI 0/AI start trig) |

| Output Coupling | DC output coupling |

| Maximum Working Voltage | ± 11 V |

| FIFO Buffer Size | 512 samples |

| Connector Type | 68 – pin male SCSI – II type I/O connector |

| Physical Dimensions | 6.3 x 3.9 in |

| Weight | 7.2 oz |

| Operating Temperature Range | 0 to 55 °C |

| Storage Temperature Range | – 20 to 70 °C |

| Humidity Range | Non – specified in common sources, but typically suitable for normal indoor humidity conditions |

| Recommended Warm – up Time | 15 minutes |

| Calibration Interval | 1 year |

| End – of – Life Status | Announced by National Instruments, but still available for purchase and repairs from some sources |

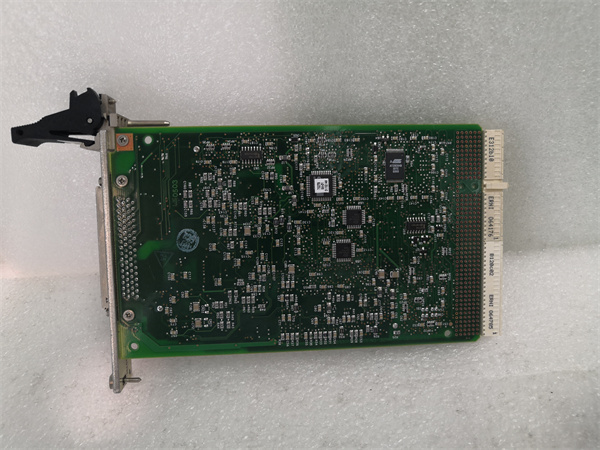

NI PXI-6052E

2. Product Introduction

The NI PXI – 6052E is a high – performance multifunction data acquisition (DAQ) device, designed as a single – slot PXI module. It is a part of NI’s full – featured E series, renowned for delivering reliable and efficient data acquisition capabilities.

With 16 analog input channels that can be configured as either 16 single – ended or 8 differential channels (software – selectable on a per – channel basis), the PXI – 6052E offers great flexibility in connecting to a wide range of sensors. For example, in a temperature – monitoring network with multiple thermocouples, the single – ended configuration can be used to connect each thermocouple’s output to an individual input channel. In a more complex industrial scenario where noise immunity is crucial, the differential configuration can be selected to measure the voltage difference between two wires, effectively reducing the impact of common – mode noise.

The 16 – bit resolution ensures high – precision measurements, making it suitable for applications that require accurate data acquisition. Whether it’s measuring small voltage changes in a scientific experiment or monitoring minute variations in industrial processes, the PXI – 6052E can capture these 细微变化 with great accuracy.

3. Core Advantages and Technical Highlights

3.1 High – Speed Sampling

The PXI – 6052E boasts a maximum sampling rate of 333 ks per second. This high – speed sampling capability allows for the rapid acquisition of data, which is essential in applications such as high – speed signal monitoring and real – time control systems. In a motor – control application, for instance, the high sampling rate enables the DAQ device to quickly capture the motor’s current and voltage signals, allowing for precise control and rapid response to any changes in the motor’s operating conditions.

3.2 Multiple Triggering Options

Equipped with analog and digital triggering features, the PXI – 6052E provides enhanced flexibility in data acquisition. Analog triggering can be used when the acquisition needs to be initiated based on a specific voltage level in the analog input signal. For example, in a chemical reaction monitoring system, when the voltage output from a sensor indicating a certain chemical concentration reaches a pre – defined threshold, the analog trigger can start the data acquisition process. Digital triggering, on the other hand, can be used in scenarios where a digital signal, such as a pulse from a digital sensor or a control signal from a PLC, is used to trigger the data acquisition.

3.3 Versatile Counter/Timers

The two 24 – bit, 20 MHz counter/timers on the PXI – 6052E are useful for a wide range of applications. They can be used for tasks such as measuring the frequency of a periodic signal, counting the number of events in a digital input, or generating precise time – based signals for control purposes. In a manufacturing plant, these counter/timers can be used to count the number of products passing through a conveyor belt or to control the timing of a robotic arm’s movements.

3.4 Compatibility with Multiple Software Environments

The PXI – 6052E offers real – time performance with LabVIEW, one of NI’s flagship software platforms. It is also fully compatible with other popular software packages and application development environments (ADEs) such as VI Logger, Measurement Studio, and programming languages like Visual Basic, C#, and C/C++. This broad compatibility allows users to choose the software environment that best suits their development needs and existing infrastructure. For example, a development team already proficient in C++ can use the PXI – 6052E in their projects without having to learn a new programming language.

4. Typical Application Scenarios

4.1 Industrial Automation

In industrial automation settings, the PXI – 6052E can be used to monitor and control various processes. It can connect to sensors that measure parameters such as temperature, pressure, flow rate, and vibration in manufacturing plants. By accurately acquiring analog and digital signals from these sensors, the PXI – 6052E provides the data necessary for a central control system to make real – time decisions. For example, in a food – processing factory, the device can monitor the temperature and pressure of the cooking and packaging processes, ensuring product quality and safety. In a semiconductor manufacturing facility, it can be used to monitor the vibration levels of precision equipment, preventing damage to delicate components.

4.2 Test and Measurement in Research Labs

In research laboratories, the PXI – 6052E is a valuable tool for test and measurement applications. It can be used to acquire data from a variety of experimental setups. For example, in a physics experiment studying the behavior of materials under different electrical fields, the PXI – 6052E can measure the voltage and current signals with high precision. In a biology research project focused on monitoring the electrical activity of cells, the device can capture the weak analog signals generated by the cells. Its high – speed sampling and accurate measurement capabilities make it suitable for experiments that require rapid data acquisition and detailed analysis.

4.3 Condition Monitoring in Power Systems

For power systems, the PXI – 6052E can be used for condition monitoring of electrical equipment. It can measure parameters such as voltage, current, and power factor in power generation, transmission, and distribution systems. In a power plant, the device can monitor the performance of generators by measuring their output voltage and current. In a smart grid, it can be used to monitor the power quality at different nodes, detecting any anomalies such as voltage sags, swells, or harmonics. This information can be used to optimize the operation of the power system, improve energy efficiency, and prevent equipment failures.

NI PXI-6052E

5. Related Model Recommendations

5.1 PXI Chassis

The PXI – 6052E is designed to be installed in a PXI chassis. Different models of PXI chassis can support varying numbers of modules, allowing users to expand their data acquisition systems as needed. For example, if a user initially has a small – scale data acquisition setup with a few PXI – 6052E modules and later needs to add more modules to monitor additional sensors or perform more complex measurements, they can upgrade to a larger – capacity PXI chassis. The chassis provides the necessary power and communication backbone for the PXI – 6052E module to function properly.

5.2 Compatible Sensors and Signal Conditioning Modules

There are numerous sensors that are compatible with the PXI – 6052E. For temperature sensing, thermocouples and resistance – temperature detectors (RTDs) can be connected to the analog input channels. In pressure – sensing applications, piezoelectric pressure transducers can be used. To ensure accurate and reliable data acquisition, signal conditioning modules may also be required. These modules can amplify, filter, or convert the signals from the sensors to a format suitable for the PXI – 6052E. For example, a low – level signal from a sensor may need to be amplified using a signal conditioning module before being input into the PXI – 6052E.

6. Installation, Commissioning and Maintenance Instructions

6.1 Installation Preparation

Before installing the PXI – 6052E, ensure that the PXI chassis is powered off. Identify an appropriate slot in the PXI chassis for the module. Gather any necessary tools, such as a screwdriver if required to secure the module in place. When handling the PXI – 6052E, be careful not to damage the connectors or any of the internal components. If connecting sensors or signal conditioning modules to the device, make sure that the wiring is properly prepared, with the correct gauge of wire and appropriate connectors.

6.2 Commissioning Steps

Once the PXI – 6052E is installed, power on the PXI chassis. Use the appropriate software, such as NI – MAX (Measurement & Automation Explorer), to configure the module. Set the input ranges, input configurations (single – ended or differential), and other parameters according to the requirements of the application. Calibrate the module using the NIST – traceable calibration certificate provided with the module to ensure accurate measurements. Test the module by applying known input signals (either from calibration sources or test sensors) and verifying that the readings on the software match the expected values.

6.3 Maintenance Suggestions

Regularly inspect the PXI – 6052E for any signs of physical damage, such as bent connectors or cracks on the module casing. Check for loose connections between the module and the PXI chassis, as well as between the module and the sensors or signal conditioning modules. If there are issues with data acquisition, such as incorrect readings or excessive noise, first check the input ranges, input configurations, and calibration settings. If the problem persists, refer to the user manual for troubleshooting steps. In case of a malfunction, if a replacement part is needed, always use genuine NI replacement parts to maintain the performance and compatibility of the module. Periodically clean the module to remove any dust or debris that may have accumulated, as this can affect the electrical performance of the module.

7. Service and Guarantee Commitment

Although the end – of – life status of the PXI – 6052E has been announced by National Instruments, some sources still offer purchase and repair services. NI has a reputation for providing quality products, and during its production lifecycle, the PXI – 6052E underwent rigorous testing to meet high – performance and reliability standards. NI provides detailed user manuals and installation guides, which are available online for easy access. Technical support was accessible through user forums and NI’s official channels during its active production phase. Even now, users can still find valuable resources and community – driven support to address any issues they may encounter. While the warranty terms may vary depending on the source of purchase, the initial design and manufacturing quality of the PXI – 6052E give users some confidence in its long – term use for less – critical or legacy data acquisition and control needs.