Description

1. Detailed Parameter Table

| Parameter Name | Parameter Value |

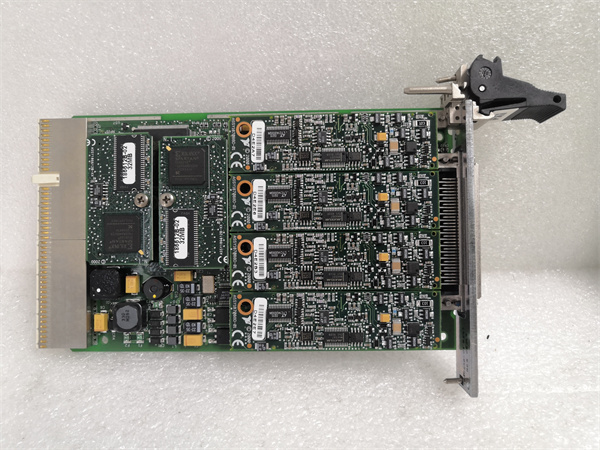

| Product Model | PXI-6115 |

| Manufacturer | National Instruments (NI) |

| Product Category | 16-Channel, 16-Bit, High-Speed Multifunction DAQ Module |

| Input Channels | 16 single-ended or 8 differential analog input channels (software-configurable) |

| Input Ranges | ±10 V, ±5 V, ±2.5 V, ±1 V, ±0.5 V, 0-10 V, 0-5 V, 0-2 V, 0-1 V |

| Resolution | 16-bit |

| Maximum Sampling Rate | 2 MS/s (per channel, with channel scanning) |

| Output Channels | 2 analog output channels, 16-bit resolution, 1 MS/s update rate |

| Digital I/O Lines | 8 lines (configurable as input or output) |

| Counter/Timers | Two 24-bit, 80 MHz counter/timers |

| Triggering | Analog and digital triggering; support for PXI trigger lines and star trigger |

| DMA Channels | 3 DMA channels with scatter-gather capability |

| Input Impedance | 10 GΩ (for analog inputs) |

| FIFO Buffer Size | 8 kS (analog input), 2 kS (analog output) |

| Connector Type | 68-pin VHDCI (Very High-Density Cable Interconnect) |

| Physical Dimensions | 6.3 x 3.9 in |

| Weight | 7.5 oz |

| Operating Temperature Range | 0 to 55 °C |

| Storage Temperature Range | -20 to 70 °C |

| Humidity Range | 5 to 95% non-condensing |

| Calibration Interval | 1 year |

| Software Compatibility | LabVIEW, LabWindows/CVI, Measurement Studio, Visual Studio (C/C++, C#), MATLAB |

NI PXI-6115

2. Product Introduction

The NI PXI-6115 is a high-performance multifunction data acquisition (DAQ) module designed for the PXI platform, belonging to NI’s versatile M Series. It stands out for its exceptional speed and precision, making it ideal for demanding applications that require rapid data acquisition without compromising accuracy.

With 16 analog input channels that can be configured as 16 single-ended or 8 differential, the PXI-6115 offers remarkable flexibility in connecting to diverse sensors and signal sources. For example, in a high-speed manufacturing line monitoring multiple pressure transducers, the single-ended configuration allows for efficient connection of each sensor, while in a noise-prone industrial environment, the differential mode ensures robust common-mode noise rejection, critical for capturing clean signals from sensitive equipment like strain gauges.

The module’s 16-bit resolution, combined with a maximum sampling rate of 2 MS/s, enables it to capture fast-changing signals with exceptional detail. Whether measuring transient voltage spikes in power electronics or high-frequency vibrations in mechanical systems, the PXI-6115 delivers reliable, high-fidelity data to support informed decision-making in research, testing, and industrial control.

3. Core Advantages and Technical Highlights

High-Speed Sampling for Dynamic Signals

The PXI-6115’s 2 MS/s sampling rate per channel (with scanning) is a game-changer for applications involving fast transient signals. In automotive testing, for instance, it can capture rapid voltage fluctuations in engine control units during acceleration, providing engineers with insights into system behavior under extreme conditions. This speed ensures that no critical data is missed, even in scenarios where signals change in microseconds.

Advanced Triggering Capabilities

Equipped with both analog and digital triggering, the PXI-6115 offers precise control over data acquisition initiation. Analog triggering can be set to activate when a signal crosses a user-defined threshold—useful in fault-detection systems, where a sudden voltage spike indicates a potential equipment failure. Digital triggering, on the other hand, syncs acquisition with external events, such as a pulse from a motion sensor in a robotics test setup, ensuring synchronized data capture across multiple devices.

Robust Counter/Timers

The two 80 MHz counter/timers extend the module’s functionality beyond basic DAQ. They can measure frequencies up to 80 MHz, count high-speed events (like encoder pulses in motor control), or generate precise timing signals. In a semiconductor manufacturing facility, these counters can track the number of wafers passing through a processing station, while in a physics lab, they can timestamp laser pulses with nanosecond precision.

Enhanced Signal Integrity

With a 10 GΩ input impedance, the PXI-6115 minimizes signal loading, preserving the integrity of weak signals from sensors like thermocouples or photodiodes. This high impedance ensures that the module does not distort the original signal, a critical feature in low-level measurements such as biomedical signals (e.g., EEG or ECG) where signal strength is minimal.

4. Typical Application Scenarios

Aerospace and Defense Testing

In aerospace, the PXI-6115 is used to test avionics systems, capturing high-speed signals from accelerometers, gyroscopes, and pressure sensors during flight simulations. Its ability to sample at 2 MS/s allows engineers to analyze transient vibrations during takeoff or turbulence, ensuring aircraft components meet safety standards. For missile guidance system testing, the module’s precise triggering synchronizes data acquisition with ignition events, providing detailed insights into propulsion system performance.

Power Electronics and Energy Systems

In power electronics labs, the PXI-6115 monitors switching transients in inverters, converters, and motor drives. It captures voltage and current waveforms during fast switching events (microsecond-scale), helping engineers optimize efficiency and reduce electromagnetic interference (EMI). In renewable energy systems, such as solar inverters, the module tracks DC input and AC output signals to evaluate power conversion efficiency under varying sunlight conditions.

Biomedical Research

Biomedical researchers rely on the PXI-6115 for high-speed physiological signal acquisition. It can capture rapid neural impulses or muscle contractions (EMG signals) with high resolution, supporting studies on motor control or neurological disorders. The module’s low noise and high input impedance ensure that delicate signals from electrodes are not distorted, enabling accurate analysis of biological responses to stimuli.

NI PXI-6115

5. Related Model Recommendations

PXI Chassis

The PXI-6115 requires a PXI chassis for operation, such as the NI PXI-1042Q (a 14-slot chassis with integrated controller) or PXI-1031 (a compact 3-slot chassis). These chassis provide power, cooling, and a high-speed backplane for synchronizing multiple DAQ modules, ideal for building scalable systems—e.g., combining the PXI-6115 with a PXI-2597 switch module to expand channel count for large-scale testing.

Signal Conditioning Modules

For sensor-specific conditioning, pair the PXI-6115 with modules like the NI SCXI-1125 (isolated analog input conditioning) for high-voltage measurements, or SCXI-1102B (thermocouple conditioning) for temperature sensing. These modules amplify, filter, and isolate signals, ensuring compatibility with the PXI-6115’s input ranges.

Cables and Connectors

The PXI-6115 uses a 68-pin VHDCI connector, requiring compatible cables like the NI SHC68-68-EPM (shielded cable for noise-sensitive applications) or 197784-01 (ruggedized cable for industrial environments). These cables ensure reliable signal transmission between the module and external sensors or instruments.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the PXI-6115, power off the PXI chassis and ensure the workspace is clean and static-free. Use an anti-static wristband to prevent electrostatic discharge (ESD) damage to internal components. Identify an available slot in the chassis (avoiding slots reserved for controllers or timing modules) and align the module with the guide rails. Gently insert the module until it seats firmly, then secure it with the front panel screws. Prepare sensor connections using shielded cables to minimize noise, and verify that signal levels match the module’s input ranges to prevent overloading.

Commissioning Steps

Power on the chassis and launch NI MAX (Measurement & Automation Explorer) to detect the PXI-6115. Configure channel settings (single-ended/differential, input range) and trigger parameters via software. Perform a calibration check using a precision signal generator (e.g., NI PXI-4071 DMM) to verify accuracy across all ranges. Test with a known sensor signal (e.g., a function generator output) to confirm data acquisition—use LabVIEW to plot real-time waveforms and validate sampling rate and resolution.

Maintenance Suggestions

Regularly inspect the PXI-6115 for loose connectors or dust accumulation; use compressed air to clean vents and connectors monthly. Check calibration annually using NI’s calibration service or a traceable standard to maintain measurement accuracy. If signal noise increases, inspect cable shielding and grounding—ensure the module is grounded to the chassis and sensors share a common ground. For persistent issues, refer to the user manual or contact NI support for troubleshooting.

7. Service and Guarantee Commitment

NI backs the PXI-6115 with a 3-year standard warranty, covering defects in materials and workmanship. During the warranty period, NI provides free repairs or replacements for qualifying issues. Technical support is available via online resources (knowledgebase, user forums), email, and phone, with expert assistance for setup, calibration, and software integration. For out-of-warranty modules, NI offers repair services and calibration certificates to extend product lifespan. With a focus on quality and reliability, NI ensures the PXI-6115 delivers consistent performance in critical applications, backed by a global network of service partners.