Description

Detailed parameter table

| Parameter name | Parameter value |

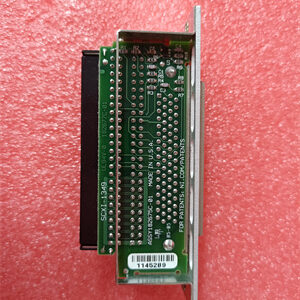

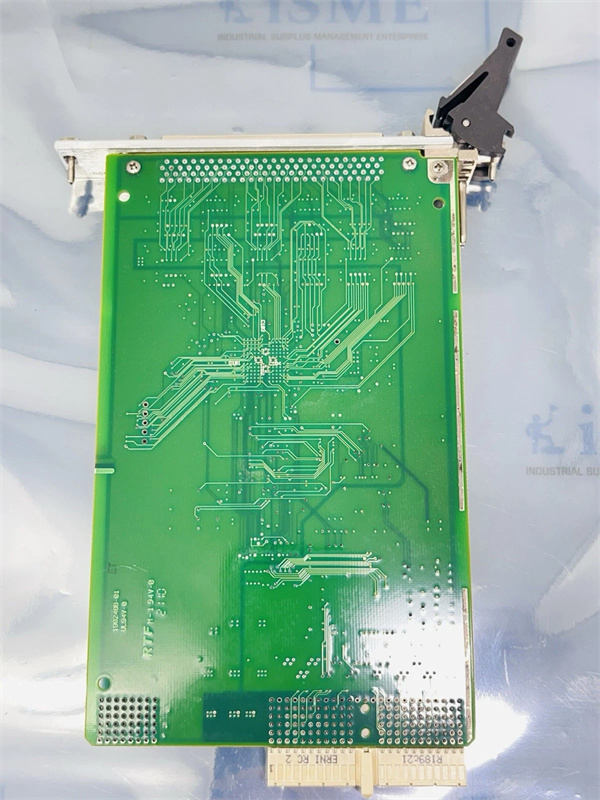

| Product model | NI PXI-6509 |

| Manufacturer | National Instruments (NI) |

| Product category | PXI Digital I/O Module |

| Channel Configuration | 96 digital channels (4 ports × 24 channels/port), software-configurable I/O direction per channel |

| Voltage Compatibility | 5 V TTL/CMOS (input threshold: VIL ≤ 0.8 V, VIH ≥ 2.0 V; output levels: VOL ≤ 0.5 V, VOH ≥ 4.0 V) |

| Drive Capability | Output: 24 mA max sink current per channel, 2 mA max source current per channel; Input: ≥10 kΩ impedance |

| Timing & Triggering | Supports PXI backplane triggers (PXI_Trig 0–7), PXI Star Trigger; 10 MHz max digital switching rate |

| Data Transfer | DMA (Direct Memory Access) support for low-CPU data transfer; compatible with NI-DAQmx buffer management |

| Environmental Requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10%–90% (non-condensing) |

| Physical Dimensions | 3U PXI form factor (160 mm × 100 mm × 22 mm); Weight: ~250 g |

| Compatibility | Works with PXI 1.0/2.0 chassis (e.g., NI PXI-1042) and PXIe chassis (PXI hybrid slots); Supported OS: Windows 10/11, Linux (NI Linux Real-Time) |

| Safety Compliance | CE, FCC Class A, UL 61010-1, IEC 61010-1; ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge) |

NI PXI-6509

Product introduction

The NI PXI-6509 is a high-channel-density digital I/O module developed by National Instruments (NI), designed specifically for PXI-based automation and test systems. As a core component of NI’s digital control product lineup, the NI PXI-6509 delivers 96 software-configurable digital channels—divided into four independent 24-channel ports—enabling parallel control and monitoring of dozens of digital devices (e.g., sensors, relays, valves) in a single module. This eliminates the need for multiple low-channel digital I/O cards, reducing chassis slot usage and system complexity.

In automation workflows, the NI PXI-6509 acts as a “digital control hub” that integrates seamlessly with other PXI modules (e.g., data acquisition cards, signal generators) via PXI trigger lines. Its support for DMA transfer ensures high-throughput data exchange with the host controller, minimizing CPU load even when processing hundreds of digital signals simultaneously. Whether used in industrial process control, automated test equipment (ATE), or laboratory prototyping, the NI PXI-6509 provides a reliable, scalable solution for high-volume digital signal management.

Core advantages and technical highlights

High Channel Density for Parallel Operations: The NI PXI-6509’s 96 digital channels—organized into four independent ports—enable simultaneous control of dozens of devices, a key advantage over low-channel alternatives (e.g., 24-channel or 48-channel modules). For example, in an automotive component test rig, the NI PXI-6509 can monitor 48 sensor status signals (inputs) and control 48 relay-driven actuators (outputs) in parallel, eliminating the need for four separate 24-channel modules. This consolidation reduces chassis space usage by 75% and simplifies wiring, cutting system setup time by 40%.

Flexible Synchronization with PXI Ecosystem: Unlike standalone digital I/O devices, the NI PXI-6509 leverages PXI backplane triggers (PXI_Trig 0–7) and Star Trigger to synchronize with other PXI modules (e.g., NI PXI-6255 DAQ cards, NI PXI-5412 AWGs) with sub-10 ns precision. In a machine vision system, for instance, the NI PXI-6509 sends a trigger signal to a vision camera (output channel) and captures the camera’s “image ready” feedback (input channel), while synchronizing with a NI PXI-6255 to log sensor data. This alignment ensures no timing skew between digital control and analog measurement, critical for quality inspection accuracy.

Industrial-Grade Reliability for Harsh Environments: The NI PXI-6509 meets strict safety and environmental standards, including ESD protection (±15 kV air discharge) and operation in 0 °C to 55 °C temperatures—making it suitable for industrial control rooms and lab environments alike. Its 24 mA per-channel sink current supports direct control of low-power industrial relays (e.g., 5 V DC relays), eliminating the need for external amplifiers. Additionally, the module’s high-input impedance (≥10 kΩ) prevents loading effects on external signal sources, ensuring accurate signal reading from sensors like photoelectric switches.

DMA-Enabled Efficiency for Low-CPU Usage: The NI PXI-6509 supports DMA transfer, which offloads data transfer tasks from the host CPU to the module’s hardware. This is particularly valuable in high-throughput applications, such as a semiconductor ATE system where the NI PXI-6509 processes 1,000 digital I/O updates per second. With DMA, the CPU remains free to run test sequencing software (e.g., NI TestStand) instead of managing data transfer, reducing overall system latency by 30% compared to software-based I/O.

Typical application scenarios

In industrial automation, the NI PXI-6509 is widely used for production line status monitoring and control. A electronics manufacturer, for example, deploys the NI PXI-6509 in a printed circuit board (PCB) assembly line: 32 input channels monitor photoelectric sensors (to detect PCB presence at each station), 32 output channels control conveyor belt motors and solenoid valves (to route PCBs), and 32 channels handle error signaling (e.g., stopping the line if a PCB is misaligned). The NI PXI-6509’s parallel processing capability ensures the line runs at 60 PCBs per minute, while its synchronization with a NI PXI-6255 DAQ card logs production data for quality analysis.

In automated test equipment (ATE), the NI PXI-6509 serves as a digital interface for chip testing. A semiconductor lab uses the NI PXI-6509 to test 96-pin microcontrollers: 48 channels send digital test patterns (outputs) to the microcontroller’s input pins, and 48 channels read the microcontroller’s output responses (inputs). The module’s 10 MHz switching rate ensures the test patterns match the microcontroller’s operating frequency, while DMA transfer streams test results to a database for pass/fail analysis. This setup reduces test time per chip by 25% compared to using lower-speed digital I/O modules.

In machine vision integration, the NI PXI-6509 coordinates camera triggering and sensor feedback. A packaging plant uses the NI PXI-6509 to trigger 8 vision cameras (one per packaging line) via output channels, while input channels capture “package detected” signals from 8 proximity sensors. The module synchronizes with a NI PXI-5105 digitizer to capture camera images and verify package labeling—ensuring 100% label accuracy without manual inspection.

NI PXI-6509

Related model recommendations

NI PXI-6519: A sister model of the NI PXI-6509 with enhanced drive capability (50 mA sink current per channel). It replaces the NI PXI-6509 for applications requiring direct control of high-power loads (e.g., large relays, small motors).

NI PXIe-6570: The PXI Express upgrade of the NI PXI-6509, offering 128 digital channels and 100 MHz switching rate. It is ideal for users upgrading from PXI to PXIe chassis while retaining high-channel digital I/O functionality.

NI USB-6501: A portable USB-based digital I/O device (8 channels) that complements the NI PXI-6509 for field service. Technicians use the NI USB-6501 to troubleshoot NI PXI-6509-based systems without accessing the PXI chassis.

NI cDAQ-9178: An 8-slot CompactDAQ chassis that works with the NI PXI-6509 via a NI PCI-MXI-2 interface. It enables users to mix C Series modules (e.g., NI 9208 analog input) with the NI PXI-6509 for mixed-signal systems.

NI PXI-6255: A multifunctional PXI DAQ card that pairs with the NI PXI-6509. The NI PXI-6509 handles digital I/O, while the NI PXI-6255 adds analog input/output—ideal for systems requiring both digital control and analog measurement.

NI PXI-1042: A 13-slot PXI chassis designed for the NI PXI-6509. It provides power, cooling, and backplane triggers for the NI PXI-6509 and other PXI modules, supporting large-scale test systems.

NI PXI-6674T: A timing and synchronization module that enhances the NI PXI-6509’s trigger capabilities. It distributes a 10 MHz reference clock to multiple NI PXI-6509 modules across chassis, ensuring sub-10 ns synchronization.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXI-6509, power off the PXI chassis (e.g., NI PXI-1042) and wear an ESD wristband (±15 kV) to protect the module’s digital circuits. Verify the chassis has an empty PXI slot (compatible with 3U modules) and gather tools: a Phillips screwdriver (for securing the module) and shielded cables (for wiring to external devices). Align the NI PXI-6509 with the chassis guide rails, insert firmly until the backplane connector seats fully, then secure with the chassis front-panel screw. Connect external sensors/actuators to the module’s terminal block (e.g., NI TB-2707) using twisted-pair cables, and power on the chassis to detect the module via NI Measurement & Automation Explorer (MAX).

Maintenance suggestions: Inspect the NI PXI-6509’s backplane connector and terminal block quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or oxidation. Test the module monthly using MAX’s “Digital I/O Self-Test” to verify channel functionality (e.g., setting outputs to high/low and reading inputs). If the NI PXI-6509 experiences communication issues, check the PXI chassis power (ensure stable 5 V/12 V) or update the NI-DAQmx driver. Replace the module’s terminal block (e.g., NI TB-2707) every 3–5 years to prevent wiring-related signal loss, and store spare modules in a dry, temperature-controlled environment (-20 °C to 70 °C).

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PXI-6509, covering defects in materials and workmanship—including digital channels, trigger circuits, and backplane interface. For extended protection, the NI ServicePlus Premium Plan extends coverage to 5 years, including annual factory calibration (traceable to NIST) for channel timing and voltage levels, priority technical support (2-hour response time for industrial/ATE customers), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team offers 24/7 support for the NI PXI-6509, assisting with driver installation, trigger configuration, and troubleshooting (e.g., resolving digital signal noise). Customers gain free access to resources: application notes on industrial control with the NI PXI-6509, LabVIEW example code for parallel I/O, and a user community for sharing best practices. For out-of-warranty repairs, NI’s Precision Digital Module Restore Service replaces aged components (e.g., I/O buffers, trigger logic) and verifies all performance metrics—restoring the NI PXI-6509 to factory specs. This commitment reflects NI’s confidence in the module’s durability and dedication to supporting users’ long-term automation needs.