Description

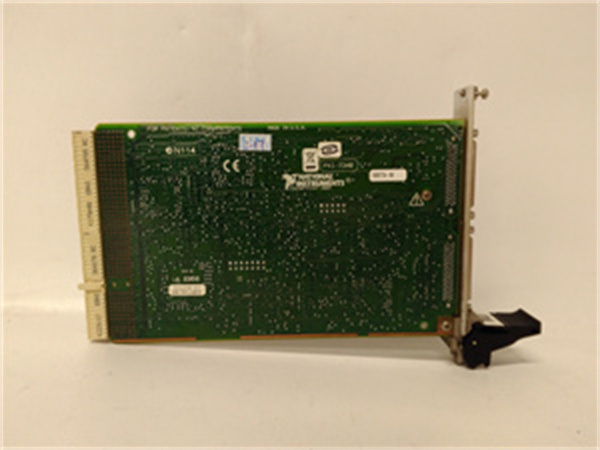

NI PXI-7344 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXI-7344 |

| Manufacturer | NI |

| Product category | PXI Motion Controller |

| Number of Axes | 4 (simultaneous control) |

| Control Modes | Position, velocity, torque (with compatible drives) |

| Positioning Resolution | Up to 32-bit quadrature encoder input |

| Maximum Encoder Input Frequency | 20 MHz |

| Trajectory Modes | Point-to-point, linear interpolation, circular interpolation |

| S-curve Profiling | Yes, with adjustable acceleration/deceleration |

| Pulse Output Types | Step/direction, quadrature, PWM |

| Maximum Pulse Output Frequency | 10 MHz |

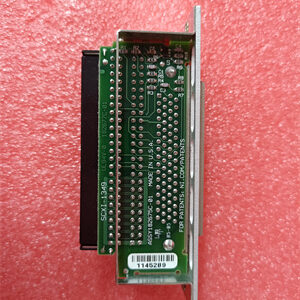

| Digital I/O | 16 dedicated general-purpose digital I/O lines |

| Triggering | PXI trigger lines, software triggers, encoder markers |

| PXI Bus Compatibility | PXI, CompactPCI |

| Form Factor | 3U PXI module |

| Operating Temperature | 0 °C to 55 °C |

| Weight | 14 oz (397 g) |

| Part Numbers | 777344-01 (Standard), 777344-02 (Extended temperature) |

| Software Compatibility | LabVIEW, NI Motion Assistant, C/C++ APIs |

NI PXI-7344

Product introduction

The NI PXI-7344 is a high-performance 4-axis motion controller designed for precision motion control applications in automated test and manufacturing systems. As part of NI’s motion control portfolio, this 3U PXI module integrates seamlessly into PXI and CompactPCI chassis, providing a scalable solution for multi-axis synchronization.

The PXI-7344 delivers advanced motion control capabilities, including position, velocity, and torque control modes, making it suitable for a wide range of applications from semiconductor wafer handling to automated assembly. With support for 20 MHz encoder inputs and 10 MHz pulse outputs, it ensures precise positioning and smooth trajectory execution. Its compatibility with industry-standard software tools like LabVIEW and NI Motion Assistant simplifies programming, allowing engineers to focus on optimizing motion profiles rather than low-level controller configuration. Whether used in research laboratories or high-volume production lines, the PXI-7344 provides reliable, deterministic motion control as a core component of automated systems.

Core advantages and technical highlights

Multi-Axis Synchronization: The NI PXI-7344 excels at coordinating 4 axes simultaneously, with sub-microsecond synchronization between axes. This capability is critical in applications like CNC machining or 3D printing, where precise relative positioning between axes directly impacts part quality. The controller’s ability to execute complex interpolated trajectories (linear and circular) ensures smooth motion paths, reducing wear on mechanical components and improving overall system accuracy.

High-Speed Feedback and Control: With 20 MHz encoder input frequency and 10 MHz pulse output, the PXI-7344 maintains tight control loops even in high-speed motion scenarios. This performance is essential for applications such as pick-and-place machines, where rapid acceleration/deceleration and precise stopping positions are required. The 32-bit encoder resolution ensures that even 微小位置变化 (tiny position changes) are detected, enabling nanometer-level positioning in precision systems.

Flexible Trajectory Planning: The PXI-7344 offers S-curve profiling with adjustable acceleration and deceleration parameters, allowing engineers to optimize motion profiles for specific applications. This feature reduces mechanical stress in systems with delicate components, such as semiconductor handling equipment, while maintaining cycle time efficiency. The controller’s support for multiple trajectory modes (point-to-point, interpolated) provides versatility across different motion requirements, from simple positioning tasks to complex contouring operations.

Seamless System Integration: As a PXI module, the PXI-7344 leverages the PXI backplane for high-speed communication and synchronization with other instruments, such as data acquisition modules or vision systems. This integration eliminates the need for external cabling between components, reducing system complexity and improving reliability. The module’s 16 digital I/O lines and support for PXI triggers enable easy interfacing with limit switches, grippers, and other peripherals, creating a cohesive automation system.

Typical application scenarios

In semiconductor manufacturing, the NI PXI-7344 controls the precision motion of wafer handling robots and inspection stages. Its 4-axis capability allows simultaneous control of X, Y, Z, and rotational axes, enabling accurate alignment of wafers under inspection cameras. The high encoder resolution ensures that positioning errors are minimized, critical for detecting microscale defects in semiconductor devices. The controller’s fast response to limit switches and encoder markers prevents collisions, protecting expensive wafers and equipment.

In automated test systems, the PXI-7344 positions devices under test (DUTs) relative to measurement probes or sensors. For example, in automotive sensor testing, it moves DUTs through precise angular positions while data acquisition modules record sensor outputs. The synchronization between motion control and data acquisition via PXI triggers ensures that measurements are taken at exact positions, improving test repeatability. The controller’s S-curve profiling reduces vibration during motion, preventing measurement errors in sensitive test setups.

In research and development laboratories, the PXI-7344 supports custom motion systems for scientific experiments. Whether controlling a 3-axis stage for laser scanning microscopy or positioning samples in a material testing machine, its flexibility allows researchers to implement unique motion profiles. Integration with LabVIEW enables real-time adjustment of motion parameters based on experimental feedback, creating adaptive control systems that respond to changing conditions.

NI PXI-7344

Related model recommendations

NI PXI-7354: A higher-performance 4-axis motion controller with 40 MHz encoder inputs and 20 MHz pulse outputs, offering an upgrade path from the PXI-7344 for applications requiring faster motion or higher resolution.

NI PXI-7330: A 3-axis motion controller in the same product family, ideal for systems with fewer axes where the PXI-7344‘s 4-axis capability isn’t required, providing a cost-effective alternative.

NI PCI-7344: The PCI-bus version of the PXI-7344, offering identical motion control features but designed for integration into desktop computers rather than PXI chassis, suitable for benchtop setups.

NI PXI-6602: A timing and synchronization module that complements the PXI-7344 in large-scale systems, providing additional trigger lines and clock sources to synchronize multiple motion controllers.

NI PXIe-7966R: A reconfigurable I/O module that can be used with the PXI-7344 for custom motion control algorithms. When paired, they enable FPGA-based real-time control for applications requiring ultra-low latency.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXI-7344, power off the PXI or CompactPCI chassis and ensure it has an available 3U slot. Inspect the module’s connectors for damage and clean the chassis slot with compressed air if necessary. Use anti-static precautions, including a wrist strap, when handling the module to prevent electrostatic discharge. Verify compatibility with your motion drives and encoders, ensuring cable lengths meet the controller’s signal integrity specifications (maximum 5 meters for encoder cables).

Commissioning: Install NI Motion Driver software (version 8.3 or later) on the host controller before powering on the system. After inserting the PXI-7344 into the chassis, launch NI Measurement & Automation Explorer (MAX) to detect the module and configure basic settings (axis names, encoder types). Use NI Motion Assistant to create and test initial motion profiles, verifying encoder feedback and drive response. Calibrate each axis by performing a reference move to establish home positions, and test limit switches to ensure proper safety interlocks. Validate multi-axis synchronization with a circular interpolation test, checking for positional errors using a laser interferometer if available.

Maintenance suggestions: Regularly inspect cables connecting the PXI-7344 to drives and encoders for secure connections and physical damage, as loose connections can cause position errors or system faults. Clean encoder connectors annually with contact cleaner to prevent signal degradation. Monitor system performance using NI Motion Monitor software, tracking axis following errors to detect mechanical wear or drive issues early. Update motion driver software periodically to access performance improvements, but verify compatibility with existing application software before upgrading. In case of synchronization issues, check PXI backplane connectivity and ensure all modules share a common system clock.

Service and guarantee commitment

NI backs the PXI-7344 with a 2-year warranty covering manufacturing defects, providing free repair or replacement of faulty modules during this period. Calibration services are available through NI Service Centers, ensuring the controller maintains specified performance metrics with traceable calibration to international standards.

Technical support is available via phone, email, and online resources, with specialized motion control engineers assisting with system design, programming, and troubleshooting. The NI website offers application notes, example code, and user manuals to guide installation and optimization. For custom integration projects, NI provides professional services to help implement complex motion control systems using the PXI-7344, ensuring customers achieve their performance goals efficiently. This comprehensive support ecosystem reflects NI’s commitment to customer success with their motion control products.