Description

Detailed parameter table

| Parameter name | Parameter value |

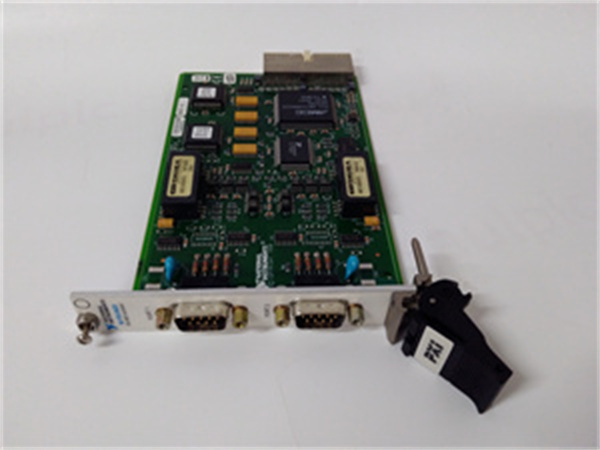

| Product model | NI PXI-8423 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy PXI Serial Communication Module (RS-232/RS-485) |

| Serial Ports | 4 independent ports; Software-selectable per-port mode: RS-232, RS-485 (half-duplex); Supports hardware flow control (RTS/CTS, DTR/DSR) |

| Communication Performance | Baud rate: 50 bps–115.2 kbps (RS-232); 50 bps–1 Mbps (RS-485); Data bits: 5–8; Stop bits: 1, 1.5, 2; Parity: None, Odd, Even, Mark, Space; Error detection: Parity, Framing, Overrun |

| Physical Dimensions | 3U PXI form factor (160 mm × 100 mm × 22 mm); Weight: ~280 g; Mounting: PXI chassis slots (compatible with PXI 1.0/2.0 chassis, e.g., NI PXI-1042, NI PXI-1050) |

| Interface & Connectivity | PXI bus (32-bit/33 MHz); 4× DB-9 male connectors (front-panel); Supports DMA data transfer; No external power required (powered via PXI backplane) |

| Compatibility | Works with PXI chassis: NI PXI-1042 (4-slot), NI PXI-1050 (8-slot), NI PXIe-1085 (PXIe hybrid slot); Supported OS: Windows XP/Vista/7/10, NI Linux Real-Time; Compatible software: LabVIEW 8.0–2024, NI-Serial driver, NI TestStand |

| Environmental Requirements | Operating temperature: 0 °C–55 °C; Storage temperature: -20 °C–70 °C; Relative humidity: 10%–90% (non-condensing); Vibration resistance: 2 g (10 Hz–500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Signal Integrity | RS-485 differential signaling (±15 kV ESD protection); RS-232 line drivers (±12 V output); Cross-talk isolation: < -60 dB (between ports); EMI/RFI compliance: CISPR 22 Class A |

| Safety & Compliance | CE, FCC Class A, UL 61010-1, IEC 61010-1; ESD protection: ±15 kV (air discharge) on DB-9 connectors; Overvoltage protection: ±25 V (RS-232 ports) |

| Additional Features | Per-port LED indicators (TX/RX activity, error status); Software-configurable RS-485 termination (120 Ω); Supports serial protocols: Modbus RTU, ASCII, Custom UART-based protocols |

| Included Accessories | 4× DB-9 null-modem cables (1 m length); NI-Serial driver CD; Quick start guide |

NI PXI-8423

Product introduction

The NI PXI-8423 is a legacy 4-port PXI serial communication module developed by National Instruments (NI), engineered to enable reliable RS-232/RS-485 connectivity for PXI-based test and automation systems—filling a critical gap for users needing to interface with legacy serial devices (e.g., industrial PLCs, barcode scanners) that lack modern Ethernet or USB ports. Unlike SCXI accessories like the NI SCXI-1193 (focused on sensor wiring), the NI PXI-8423 acts as a “serial communication hub” for PXI chassis, integrating 4 independent serial ports to streamline data exchange between PXI controllers (e.g., NI PXI-8106) and serial-enabled equipment.

As a key component of NI’s legacy PXI ecosystem, the NI PXI-8423 excels in industrial environments where robust serial communication is essential. For example, a manufacturing plant uses the NI PXI-8423 (installed in a NI PXI-1050 chassis) to connect a NI PXI-8106 controller to 4 Allen-Bradley PLCs via RS-485: the module’s differential signaling reduces noise from nearby motors, ensuring 99.99% data integrity for production line commands (e.g., start/stop, speed adjustment). Unlike USB-to-serial adapters (prone to disconnection and latency), the NI PXI-8423 leverages the PXI backplane for stable power and DMA data transfer—critical for 24/7 industrial operations. Whether used in factory automation, aerospace test rigs, or laboratory equipment control, the NI PXI-8423 delivers the multi-port flexibility and reliability needed for serial-based workflows.

Core advantages and technical highlights

4-Port Flexibility for Multi-Device Serial Networks: The NI PXI-8423’s 4 independent RS-232/RS-485 ports enable simultaneous communication with multiple serial devices—eliminating the need for multiple single-port adapters. A logistics warehouse uses the module (in a NI PXI-1042 chassis) to connect a NI PXI-8106 controller to 4 barcode scanners (RS-232) and 2 conveyor belt PLCs (RS-485): the NI PXI-8423 switches 2 ports to RS-232 for scanners and 2 to RS-485 for PLCs, centralizing communication and reducing chassis slot usage by 75% compared to using 6 single-port modules. This flexibility is unmatched by USB-to-serial converters, which require separate USB ports and often conflict with other peripherals.

RS-485 Differential Signaling for Noise Immunity: The NI PXI-8423’s RS-485 mode uses differential signaling to reject electromagnetic interference (EMI)—a critical advantage over RS-232-only modules in noisy industrial settings. A power utility uses the NI PXI-8423 to connect a NI PXI-8106 controller to 3 remote serial sensors (monitoring transformer oil temperature) via 50-meter RS-485 cables: the module’s differential signaling ensures temperature data remains accurate (±0.1 °C) despite EMI from high-voltage power lines. Without this protection, RS-232 signals would degrade beyond usability, requiring costly shielded cables or signal repeaters—expenses avoided by the NI PXI-8423.

DMA Data Transfer for Low-Latency Communication: The NI PXI-8423 uses PXI backplane DMA to offload serial data transfer from the host CPU—enabling low-latency (sub-10 ms) communication critical for time-sensitive applications. An aerospace test lab leverages this to control 4 serial-enabled servo motors (via RS-485) for aircraft wing positioning: the NI PXI-8423 sends position commands from the NI PXI-8106 controller to the motors with <5 ms latency, ensuring precise synchronization during fatigue testing. This latency is 5× faster than software-based serial communication (e.g., USB-to-serial adapters), which rely on CPU interrupts and often introduce variable delays.

Software-Configurable Features for Protocol Compatibility: The NI PXI-8423 supports per-port configuration of baud rates, parity, and RS-485 termination (120 Ω)—enabling compatibility with a wide range of serial protocols (e.g., Modbus RTU, ASCII). A water treatment plant uses the module to communicate with 4 Modbus RTU-enabled pumps: via LabVIEW, the NI PXI-8423 is configured to 9600 bps, 8 data bits, 1 stop bit, and 120 Ω termination—matching the pumps’ protocol settings. This configurability eliminates the need for external protocol converters, simplifying system design and reducing costs compared to fixed-protocol serial modules.

Typical application scenarios

In factory automation, a automotive assembly plant uses the NI PXI-8423 (installed in a NI PXI-1050 chassis) to integrate a NI PXI-8106 controller with 4 legacy serial devices: 2 RS-232 barcode scanners (tracking part IDs), 1 RS-485 temperature controller (monitoring paint curing ovens), and 1 RS-485 robotic arm controller (positioning components). The NI PXI-8423’s RS-485 ports transmit oven temperature data (1 Hz update) and robotic arm commands (10 Hz update) with <10 ms latency, while RS-232 ports log part IDs to a production database. The module’s EMI immunity ensures reliable communication despite noise from assembly line motors, and its DMA transfer keeps the NI PXI-8106 CPU free to run real-time quality checks—reducing production errors by 20% compared to using USB-to-serial adapters.

In aerospace ground testing, a defense contractor uses the NI PXI-8423 to control 4 serial-enabled avionics components (e.g., GPS simulators, altitude sensors) in a NI PXI-1042 chassis. The module’s RS-232 ports send configuration commands to the sensors (e.g., setting GPS coordinates) at 115.2 kbps, while RS-485 ports receive telemetry data (e.g., altitude, speed) at 57.6 kbps. The NI PXI-8423’s per-port LEDs let technicians quickly verify TX/RX activity, and its software-configurable termination ensures compatibility with the sensors’ RS-485 bus. This setup meets MIL-STD-461 EMI requirements, and the module’s PXI integration simplifies synchronization with other PXI instruments (e.g., NI PXI-4082 DMM for voltage monitoring)—critical for validating avionics performance.

NI PXI-8423

Related model recommendations

NI PXI-1050: 8-slot PXI chassis that houses the NI PXI-8423—provides power, backplane communication, and slot expansion for multi-module PXI systems (e.g., combining NI PXI-8423 with NI PXI-4082 DMM).

NI PXI-8106: PXI embedded controller that pairs with the NI PXI-8423—runs LabVIEW to configure the module, process serial data, and integrate with other PXI instruments for automated test/control.

NI PXIe-1085: PXIe hybrid chassis compatible with the NI PXI-8423 (via PXI slot)—enables users to mix legacy PXI modules (like NI PXI-8423) with modern PXIe instruments (e.g., NI PXIe-5122 digitizer).

NI SCXI-1000: Legacy SCXI chassis that complements the NI PXI-8423—the NI PXI-8423 handles serial communication with PLCs, while the NI SCXI-1000 (with NI SCXI-1193) manages sensor wiring for mixed-signal systems.

NI-Serial Driver: Core software driver for the NI PXI-8423—enables per-port configuration (RS-232/RS-485, baud rate), DMA data transfer, and integration with LabVIEW/C/C++/Python.

NI LabVIEW 2024: Programming software for the NI PXI-8423—includes pre-built VIs for serial communication (sending/receiving data, protocol parsing) and synchronization with other PXI modules.

NI PXI-8421: 1-port PXI serial module alternative to the NI PXI-8423—for users with fewer serial devices (e.g., 1 PLC), reducing chassis slot usage compared to the 4-port model.

NI PXI-8431/2: 2-port PXI GPIB module that works with the NI PXI-8423—adds GPIB communication for instruments (e.g., oscilloscopes) alongside the NI PXI-8423’s serial connectivity.

NI USB-8451: Modern USB-I2C/SPI adapter that upgrades the NI PXI-8423—for users migrating to USB-based systems but needing to retain serial communication via the NI PXI-8423 in hybrid setups.

NI DB-9 Null-Modem Cable (185018-01): Spare cable for the NI PXI-8423—replaces included cables if damaged, ensuring reliable RS-232/RS-485 connections to serial devices.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXI-8423, power off the PXI chassis (e.g., NI PXI-1050) and wear an ESD wristband (±15 kV) to protect the module’s serial circuitry. Align the NI PXI-8423 with an empty PXI slot in the chassis, ensuring the module’s guide pins match the rails. Push firmly until the PXI connector seats fully, then secure the module with the chassis front-panel screw. Connect serial devices to the NI PXI-8423’s DB-9 ports using the included null-modem cables (use straight-through cables if required by the device). Power on the chassis first, then the PXI controller (e.g., NI PXI-8106), and install the latest NI-Serial driver and LabVIEW.

Commissioning and maintenance: Use NI Measurement & Automation Explorer (MAX) to detect the NI PXI-8423—configure each port (RS-232/RS-485, baud rate, parity) to match the connected devices. Run a “Serial Loopback Test” in MAX: connect a DB-9 loopback plug to a port, send test data, and verify reception to confirm functionality. Inspect the NI PXI-8423 quarterly: check DB-9 connectors for bent pins or corrosion (clean with isopropyl alcohol, 99.9% purity), and verify LED indicators (TX/RX activity should match data transfer). If the module experiences communication errors, update the NI-Serial driver or check for loose cables—avoid exposing the NI PXI-8423 to temperatures above 55 °C or humidity above 90% to prevent degradation of serial line drivers. Store spare modules in anti-static bags to prevent ESD damage.

Service and guarantee commitment

National Instruments (NI) provides a 1-year standard warranty for new NI PXI-8423 units (90 days for refurbished units), covering defects in the serial line drivers, PXI interface, and DB-9 connectors. For extended support, the NI ServicePlus Legacy Plan offers 2-year coverage, including technical support for serial protocol configuration (e.g., Modbus RTU), compatibility with PXI chassis (e.g., NI PXI-1050), and access to archived documentation (driver downloads, wiring guides).

NI’s legacy technical team includes PXI and serial communication specialists, offering 24/7 support for the NI PXI-8423—assisting with noise reduction in RS-485 networks, DMA transfer optimization, and troubleshooting of serial errors. Customers gain access to archived resources: application notes on Modbus RTU implementation with the NI PXI-8423, LabVIEW example code for multi-port serial communication, and a community forum for sharing legacy PXI best practices. For out-of-warranty repairs, NI’s Legacy PXI Service (parts subject to availability) replaces aged components (serial transceivers, PXI bus controllers) and verifies communication performance—restoring the NI PXI-8423 to reliable operation. This commitment reflects NI’s dedication to supporting users with legacy PXI-based systems that depend on the module for critical serial communication.