Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI PXIE-8840QC |

| Manufacturer | National Instruments (NI) |

| Product category | PXIe Rugged System Controller |

| Processor | Intel Core i7-8665UE Quad-Core (1.7 GHz base, 4.4 GHz max turbo) |

| Memory (RAM) | Up to 32 GB DDR4-2400 (non-ECC, dual-channel) |

| Storage | 512 GB / 1 TB PCIe NVMe SSD (industrial-grade, shock/vibration resistant) |

| Supported Operating Systems | Windows 10 IoT Enterprise LTSC, LabVIEW Real-Time 2020+ |

| Chassis Compatibility | All NI PXIe chassis (e.g., PXIE-1082, PXIE-1085, PXIE-1095, PXIE-1075) |

| Operating Temperature Range | -40 °C to 70 °C (extended industrial grade; -55 °C to 85 °C storage) |

| Power Consumption | 35 W (typical, from PXIe backplane; 45 W max) |

| Connectivity | 2× Gigabit Ethernet (RJ45), 4× USB 3.0 (Type-A), 1× Thunderbolt 3 (USB-C), 1× VGA |

| Weight | 2.65 lb (1.2 kg) |

| Ruggedization Ratings | 50 g peak shock (11 ms), 5-500 Hz vibration (1.0 g rms) |

| Key Functions | System control, real-time data processing, module synchronization, test sequence execution |

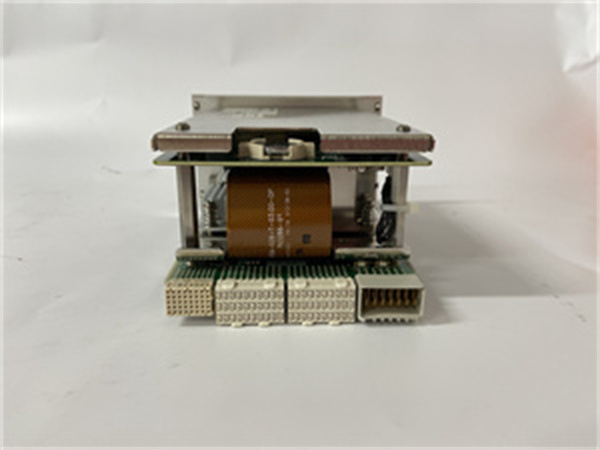

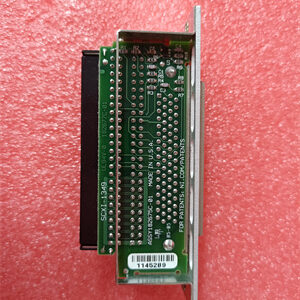

NI PXIE-8840QC

Product introduction

The National Instruments PXIE-8840QC is a flagship rugged PXIe system controller, engineered to serve as the central “brain” of high-performance test, measurement, and automation systems. As a critical component of NI’s PXIe modular ecosystem, it combines quad-core processing power with industrial-grade durability—making it ideal for applications where reliable, real-time control is required in harsh environments.

Designed to unify and manage PXIe modules (e.g., digital I/O, analog acquisition, timing modules), the NI PXIE-8840QC leverages its Intel Core i7-8665UE quad-core processor to handle simultaneous tasks: executing test sequences, processing high-volume data from connected modules, and synchronizing system-wide operations. When paired with NI’s LabVIEW Real-Time or Windows 10 IoT Enterprise, the NI PXIE-8840QC enables deterministic control (sub-millisecond latency) for time-critical applications, while its industrial-grade SSD and extended temperature range ensure reliability in factory floors, aerospace test cells, or field-deployed systems.

Core advantages and technical highlights

Quad-Core Processing for Multitask Efficiency:

The NI PXIE-8840QC’s Intel Core i7-8665UE quad-core processor (1.7 GHz base, 4.4 GHz turbo) delivers exceptional multitasking performance—critical for complex PXIe systems. Unlike dual-core controllers, it can simultaneously run test software, process data from 8+ connected modules (e.g., NI PXIE-6556 digital I/O, NI PXIE-5122 analog input), and communicate with host PCs via Ethernet/Thunderbolt. For example, in semiconductor ATE systems, the NI PXIE-8840QC can execute test patterns on a NI PXIE-6556 while analyzing results in real time, cutting test cycle times by up to 30%.

Rugged Design for Harsh Environments:

With a -40 °C to 70 °C operating temperature range, 50 g shock resistance, and 1.0 g rms vibration tolerance, the NI PXIE-8840QC outperforms commercial-grade controllers in harsh conditions. Its industrial-grade PCIe NVMe SSD resists data corruption from shock/vibration, while its sealed connectors prevent dust/moisture ingress. This ruggedness makes it ideal for aerospace/defense applications (e.g., field-deployed avionics testing) or industrial automation (e.g., factory floors with temperature fluctuations), where commercial controllers would fail prematurely.

Deterministic Real-Time Control:

When running LabVIEW Real-Time, the NI PXIE-8840QC delivers sub-millisecond latency for deterministic control—essential for applications like motion synchronization or closed-loop test systems. It integrates seamlessly with NI timing modules (e.g., NI PXIE-6674T) to distribute precision clock signals to all PXIe modules, ensuring synchronized operation. For automotive ECU testing, this means the NI PXIE-8840QC can trigger sensor simulations and capture ECU responses with microsecond-level alignment, improving test accuracy.

Flexible Connectivity and Storage:

The NI PXIE-8840QC offers versatile connectivity: 2× Gigabit Ethernet for networked test stations, 4× USB 3.0 for peripheral devices (e.g., keyboards, external storage), and 1× Thunderbolt 3 for high-speed data transfer (up to 40 Gbps) to host PCs. Its configurable storage (512 GB/1 TB industrial SSD) provides ample space for test logs, firmware, and software—eliminating the need for external hard drives. This flexibility reduces system complexity and ensures compatibility with legacy and modern test setups.

Typical application scenarios

In aerospace and defense, the NI PXIE-8840QC powers field-deployed avionics test systems. It controls modules like the NI PXIE-6556 (digital I/O) and NI PXIE-6674T (timing) to simulate aircraft sensor signals (e.g., ARINC 429) and validate avionics components. Its -40 °C to 70 °C temperature range allows operation in desert or arctic test sites, while its shock resistance withstands transportation in military vehicles. The NI PXIE-8840QC’s real-time processing ensures test results are generated on-site, reducing the need for post-test data analysis.

In semiconductor manufacturing, the NI PXIE-8840QC serves as the controller for high-throughput memory chip test systems. It coordinates the NI PXIE-6556 (generating 100 MHz read/write patterns) and NI PXIE-5122 (measuring analog signals from chips) to test hundreds of DRAM modules per hour. Its quad-core processor handles simultaneous pattern generation and error analysis, while the industrial SSD stores test logs for traceability. This setup cuts test time by 25% compared to dual-core controllers, boosting production efficiency.

In industrial automation, the NI PXIE-8840QC enables real-time control of smart factory systems. It connects to digital I/O modules (e.g., NI PXIE-6556) to monitor conveyor belt sensors and trigger robotic arms, while processing data from temperature/pressure sensors via analog modules. Its rugged design withstands factory floor vibration and temperature swings, and LabVIEW Real-Time ensures deterministic control (sub-10 ms response time) for critical processes like automotive part assembly—reducing downtime and defects.

NI PXIE-8840QC

Related model recommendations

NI PXIE-8860: An upgraded controller in the same PXIe series as the NI PXIE-8840QC, featuring an Intel Core i9-1195G7 octa-core processor. It’s ideal for large-scale systems (e.g., multi-DUT semiconductor testing) that require more processing power than the NI PXIE-8840QC.

NI PXIE-8821: A cost-effective dual-core alternative to the NI PXIE-8840QC, with an Intel Core i5-8365UE processor. It’s suitable for smaller test setups (e.g., single-module analog acquisition) where quad-core performance is unnecessary.

NI PXIE-1085: An 18-slot PXIe chassis designed to host the NI PXIE-8840QC. It provides high-bandwidth backplane connectivity (1 GB/s per slot) to support the controller’s data throughput and includes industrial-grade cooling for -40 °C to 70 °C operation.

NI PXIE-6556: A high-speed digital I/O module that pairs with the NI PXIE-8840QC for pattern generation/acquisition. The NI PXIE-8840QC controls the NI PXIE-6556 to generate 100 MHz digital signals, critical for semiconductor or avionics testing.

NI PXIE-6674T: A PXIe timing module that synchronizes with the NI PXIE-8840QC to distribute precision clock signals across all PXIe modules. This ensures synchronized operation in complex systems (e.g., mixed-signal test setups).

NI PXIE-5122: A high-speed analog input module complementary to the NI PXIE-8840QC. The controller processes analog data (e.g., voltage waveforms) acquired by the NI PXIE-5122, enabling mixed-signal test coverage.

NI LabVIEW Real-Time: Software optimized for the NI PXIE-8840QC, enabling deterministic control and real-time data processing. It simplifies programming of synchronized test sequences and integrates with all NI PXIe modules.

NI PXIE-8840: The non-rugged predecessor of the NI PXIE-8840QC, with the same quad-core processor but a narrower operating temperature range (0 °C to 55 °C). It’s a replacement option for lab-based systems where industrial ruggedness isn’t required.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PXIE-8840QC, verify that the target PXIe chassis (e.g., NI PXIE-1085) has a dedicated controller slot and supports the module’s power requirements (35 W typical). Ensure the installation environment meets the controller’s temperature (-40 °C to 70 °C) and vibration (1.0 g rms) specs—avoid areas with direct sunlight or excessive dust. Required tools include a Phillips-head screwdriver (to secure the controller to the chassis) and ESD protection gear (wrist strap, mat) to prevent electrostatic damage. Update the chassis firmware via NI Measurement & Automation Explorer (MAX) before inserting the NI PXIE-8840QC to ensure compatibility. Always power off the chassis during installation to protect the backplane and controller.

Maintenance suggestions

For daily maintenance of the NI PXIE-8840QC, inspect the front-panel connectors (Ethernet, USB, Thunderbolt) monthly for corrosion or debris—clean with a dry, lint-free cloth if needed. Monitor the controller’s temperature and CPU usage via MAX; sustained CPU loads above 90% may indicate software inefficiencies, while temperatures exceeding 70 °C require improved chassis cooling. Every 3 months, update the controller’s firmware and OS (Windows/LabVIEW Real-Time) to access stability improvements. For storage maintenance, run monthly SSD health checks via the OS to detect potential drive failures early. Avoid subjecting the NI PXIE-8840QC to unnecessary shock (e.g., dropping tools near the chassis), as this can damage the industrial SSD or processor.

Service and guarantee commitment

National Instruments (NI) backs the NI PXIE-8840QC with a 3-year standard warranty—longer than most industrial controllers—covering defects in materials and workmanship under normal use. If the NI PXIE-8840QC fails during the warranty period, NI provides free repair or replacement, with expedited service options (24-hour turnaround) for critical applications like semiconductor production or aerospace testing. NI’s global technical support team is available 24/7 via email, phone, and online chat, offering assistance with OS configuration, LabVIEW Real-Time integration, and troubleshooting connectivity issues. Additionally, NI provides lifetime access to firmware updates, driver downloads, and application notes for the NI PXIE-8840QC, ensuring the controller remains compatible with new PXIe modules and software. This commitment reflects NI’s confidence in the NI PXIE-8840QC’s ruggedness and performance, helping customers maximize their long-term investment.