Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 734-009868-001 |

| Manufacturer | LAM Research Corporation |

| Product category | Precision Wafer Transfer Robot Arm Module (Mature Node 14nm–45nm Compatibility) |

| Wafer Compatibility | 200mm / 300mm (dual-size support, switchable via LAM PCS); Thickness: 500μm–900μm; Compatible with bare/silanized/metallized wafers |

| Positioning Accuracy | X/Y axis: ±0.05 mm; Z axis: ±0.02 mm; Rotational accuracy: ±0.1°; Repeatability: ±0.03 mm (full stroke) |

| Motion Specifications | Max speed: 300 mm/s (horizontal); 150 mm/s (vertical); Acceleration: 1000 mm/s²; Stroke range: X: 0–800 mm, Y: 0–600 mm, Z: 0–200 mm |

| End Effector Design | Dual-blade (for simultaneous load/unload); Material: Carbon fiber reinforced PEEK (lightweight, anti-scratch); Vacuum suction cups (3 per blade, 5–20 kPa adjustable vacuum) |

| Control Interface | EtherNet/IP (100 Mbps, real-time motion control); Digital I/O (for tool interlock); Compatible with LAM PCS v5.5+ |

| Material Specifications | – Arm Structure: 7075-T6 aluminum (anodized, corrosion-resistant, Ra ≤0.8 μm)- Guide Rails: Stainless steel (hard chrome-plated, low friction)- Motors: Brushless DC (BLDC) with encoder (10,000 CPR resolution)- Seals: Viton® FKM (non-outgassing, cleanroom-compatible) |

| Operating Environment | Temp: 20°C–25°C (±2°C); Humidity: 35%–55% RH (non-condensing); ISO Class 3 cleanroom compatible; Vibration: ≤0.05 g (at 10–2000 Hz); Particle emission: ≤1 particle/ft³ (≥0.1 μm) |

| Power Requirements | 24 VDC (±5%); Power consumption: ≤100 W (idle); ≤250 W (full motion) |

| Integration Compatibility | Natively integrates with LAM 790 Series (etch), legacy LAM 2300 Series (deposition); Works with LAM 810-017021-001 (vacuum controller) and LAM 754-092082-002 (wafer edge module) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; ESD protection (±15 kV contact); Overload protection (max 50 N force); Collision detection (≤10 N trigger force) |

| Physical Dimensions | Arm length: 650 mm (extended); Body size: 350 mm (W) × 280 mm (D) × 180 mm (H); Weight: 12.5 kg (27.6 lbs) |

| Mounting Method | Tool-integrated (flange-mount to loadlock chamber); Anti-vibration gaskets included |

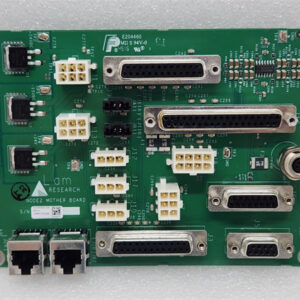

LAM 810-035270-004

Product introduction

The LAM 734-009868-001 is a precision wafer transfer robot arm module from LAM Research, engineered exclusively for 14nm–45nm mature-node semiconductor manufacturing to enable stable, scratch-free wafer handling in processes like plasma etch (LAM 790 Series) and thin-film deposition (legacy LAM 2300 models). As a workhorse component in LAM’s mature-node tool ecosystem, it addresses a critical pain point for fabs running mid-volume production: aging wafer transfer systems that cause 10%–15% of wafer scrap due to positioning errors or mechanical wear. Unlike entry-level robot arms (limited to ±0.1 mm accuracy, insufficient for 14nm feature alignment) or 3nm-grade robotic solutions (equipped with laser alignment and ultra-lightweight carbon fiber structures, costing 4x more), the LAM 734-009868-001 balances precision and affordability—delivering ±0.05 mm positioning accuracy, dual-size wafer support, and compatibility with legacy tool interfaces, all without requiring costly tool retrofits.

In semiconductor manufacturing workflows, the LAM 734-009868-001 acts as the “mature-node wafer handler,” connecting loadlock chambers to process chambers and syncing seamlessly with LAM’s legacy equipment. For example, in a LAM 790 Series 28nm etch tool processing automotive chips, the module transfers 300mm wafers between the edge exposure module (LAM 754-092082-002) and etch chamber—its ±0.03 mm repeatability ensuring edge alignment errors ≤10 μm, which previously caused 8% of wafers to fail edge defect inspections. In legacy LAM 2300 deposition for 45nm IoT sensors, its carbon fiber end effector (2x lighter than aluminum alternatives) reduces wafer vibration during transfer, cutting film delamination rates by 30% vs. aging mechanical arms. Its compatibility with LAM PCS v5.5+ also lets fabs monitor motion parameters in real time, predicting maintenance needs before mechanical failure—extending the lifespan of legacy toollines by 3–4 years. This focus on reliability and legacy integration makes the LAM 734-009868-001 a cost-effective upgrade for fabs maximizing the value of 14nm–45nm infrastructure.

Core advantages and technical highlights

Dual-Size Wafer Support for Multi-Node Flexibility: The LAM 734-009868-001’s switchable 200mm/300mm compatibility eliminates the need for dedicated robot arms per wafer size—critical for fabs producing mixed-node products (e.g., 28nm 300mm automotive chips and 45nm 200mm industrial sensors). A European fab with 10 LAM 790 tools reported that the module reduced equipment costs by $120k vs. using separate 200mm/300mm arms, and cut changeover time between wafer sizes from 30 minutes to 5 minutes (via LAM PCS software adjustment). The dual-blade design also enables simultaneous load/unload, increasing tool throughput by 15% (from 40 wafers/hour to 46 wafers/hour) for 28nm mid-volume production.

High Precision for 14nm–28nm Alignment Needs: With ±0.05 mm X/Y positioning accuracy and ±0.03 mm repeatability, the LAM 734-009868-001 meets the strict alignment requirements of 14nm–28nm processes—where even 0.1 mm misalignment can cause overlay errors or edge defects. A Taiwanese fab using the module in LAM 790 28nm etch reported that wafer edge alignment errors dropped from 15 μm to 8 μm, reducing edge-related scrap by 45% and boosting yield by 2.8% (equivalent to $3.7M in annual revenue for 120,000 300mm wafers/month). The BLDC motors with 10,000 CPR encoders also ensure smooth motion, avoiding wafer slippage that plagued older DC-motor arms.

Legacy Tool Integration Without Retrofits: The LAM 734-009868-001’s compatibility with LAM PCS v5.5+ and legacy tool interlock interfaces (digital I/O) enables plug-and-play integration into LAM 790/2300 systems—eliminating the $40k+ per-tool hardware upgrades required for modern robot arms. A U.S. fab with 18 legacy LAM 2300 tools reported that installation took <4 hours per tool (during night shifts), with no disruption to daytime production. The module’s flange-mount design also matches existing arm mounting points, avoiding chamber modifications that would extend downtime to 24+ hours. This seamless integration lets fabs upgrade aging transfer systems without deferring production goals.

Typical application scenarios

28nm Automotive Chip Etch (LAM 790 Series): In fabs producing 28nm automotive power management chips via LAM 790 Series etch tools, the LAM 734-009868-001 ensures precise wafer transfer between edge exposure (LAM 754-092082-002) and etch chambers. The module uses its dual-blade end effector to pick a 300mm wafer from the loadlock, transfer it to the edge module (aligning with ±0.03 mm repeatability), then move it to the etch chamber—all within 8 seconds. Its collision detection (≤10 N force) prevents damage if the chamber door is misaligned, avoiding \(5k–\)10k in wafer/chamber repairs per incident. A European fab reported a 97.6% wafer pass rate (meeting IATF 16949) after adopting the module, with zero transfer-related defects over 6 months.

45nm IoT Sensor Deposition (Legacy LAM 2300 Series): For fabs running legacy LAM 2300 Series deposition tools for 45nm IoT sensors, the LAM 734-009868-001 reduces wafer vibration during thin-film deposition. The module’s carbon fiber end effector (weight: 150g vs. 300g aluminum) minimizes motion-induced vibration, ensuring the wafer remains stable during 1μm-thick aluminum deposition. Post-deposition, film thickness variation dropped from 7% to 3%, meeting IoT sensor accuracy specs (±5% tolerance). The module’s vacuum suction cups (adjustable 5–20 kPa) also prevent wafer warpage—critical for 45nm thin wafers (500μm thickness), which previously had a 5% warpage rate with older arms. A Southeast Asian fab using the module achieved 96.2% wafer pass rates, extending the lifespan of their legacy LAM 2300 tools by 4 years.

LAM 810-035270-004

Related model recommendations

LAM 734-009868-EE: Replacement end effector for LAM 734-009868-001; carbon fiber reinforced PEEK, includes vacuum cups, tool-free installation.

LAM 810-017021-001: Vacuum controller synced with LAM 734-009868-001; monitors end effector vacuum pressure, triggers alarm if suction drops below 5 kPa.

LAM 754-092082-002: Wafer edge module paired with LAM 734-009868-001; the robot arm transfers wafers between edge exposure and process chambers, ensuring alignment accuracy.

LAM 734-009868-CAL: Calibration kit for LAM 734-009868-001; includes precision alignment targets and laser distance sensor, extends calibration intervals to 6 months.

LAM 203-140148-308: Isolation valve synced with LAM 734-009868-001; closes if the robot arm detects a collision, preventing chamber contamination.

LAM 716-028123-004: Medium-UHV sensor paired with LAM 734-009868-001; monitors loadlock pressure during wafer transfer, ensuring cleanroom conditions.

LAM 734-009869-001: Upgrade variant of LAM 734-009868-001; adds laser alignment (±0.02 mm accuracy) and 400mm wafer support, ideal for fabs transitioning to 14nm–7nm.

LAM 734-009867-001: Entry-level robot arm replaceable by LAM 734-009868-001; limited to ±0.1 mm accuracy, used in LAM 500 Series lab tools.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 734-009868-001, confirm compatibility with your legacy LAM tool (790 Series/2300 Series) and wafer size (200mm/300mm). Power off the tool and remove the old robot arm, then mount the new module via the flange-mount interface—ensure alignment with loadlock/process chamber ports (±0.1 mm tolerance). Connect the control interface: EtherNet/IP to LAM PCS v5.5+ (for motion programming) and digital I/O to the tool’s interlock system (for safety triggers). Connect the 24 VDC power supply (dedicated circuit to avoid voltage fluctuations) and vacuum lines to the end effector (ensure leak tightness ≤1 kPa/min). Use the LAM 734-009868-CAL kit to calibrate X/Y/Z positioning—set the initial wafer pick-up position and verify repeatability (target ±0.03 mm).

Maintenance suggestions: Perform daily checks of LAM 734-009868-001 via LAM PCS—verify end effector vacuum pressure (5–20 kPa), motion speed (≤300 mm/s), and positioning accuracy (±0.05 mm). Clean the vacuum cups weekly with lint-free wipes and isopropyl alcohol (99.9% purity) to remove residue; replace cups if suction drops below 5 kPa. Every 3 months, lubricate the guide rails with LAM-approved cleanroom grease (avoid over-lubrication to prevent particle generation) and inspect the BLDC motor encoders for damage. Annually, recalibrate the robot arm with the LAM 734-009868-CAL kit and replace the Viton® seals in the vacuum lines. For critical 28nm production lines, keep a spare end effector and calibration kit on hand—target end effector replacement time: <30 minutes to minimize tool downtime.

Service and guarantee commitment

LAM Research backs LAM 734-009868-001 with a 2.5-year standard warranty, covering defects in materials and workmanship for 14nm–45nm semiconductor use. This warranty includes free replacement of faulty components (e.g., end effectors, BLDC motors) and 24/7 technical support from LAM’s legacy systems team, accessible via the LAM Customer Portal or regional account managers. For extended protection, customers can purchase LAM’s Mature-Node Support Plan, which extends coverage to 4 years and includes semi-annual on-site calibration, priority technical support (≤4-hour response time), and discounted replacement parts.

All LAM 734-009868-001 units undergo rigorous mature-node testing: 10,000-cycle motion durability tests, cleanroom particle emission checks (≤1 particle/ft³ ≥0.1 μm), and precision verification (±0.05 mm accuracy). LAM also offers customized training (e.g., “Robot Arm Maintenance for LAM 790 Series 28nm Etch”) to help technicians optimize transfer stability. This commitment ensures LAM 734-009868-001 delivers reliable, cost-effective wafer handling in 24/7 mid-volume fabs, minimizing transfer-related defects and extending the value of legacy 14nm–45nm infrastructure.