Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

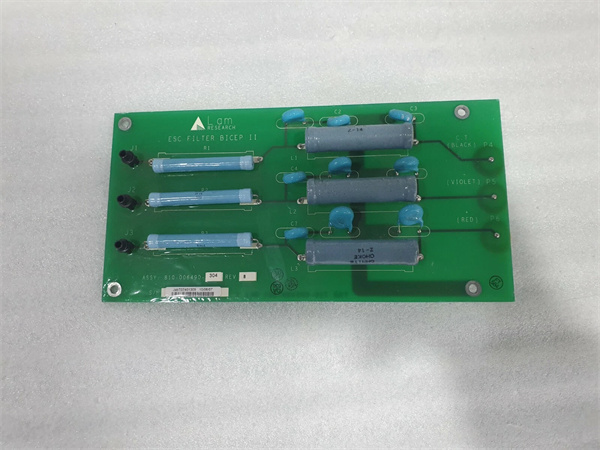

| Product model | LAM 810-006490-304 |

| Manufacturer | LAM Research Corporation |

| Product category | Advanced Entry-Level Vacuum Pressure Control Module (Mature Node 28nm–90nm Compatibility) |

| Vacuum Control Range | 5×10⁻³ Torr – 1×10⁻⁸ Torr (covers medium to high vacuum); Semi-auto range switching (800 ms response, 2 ranges: 5×10⁻³–1×10⁻⁵ / 1×10⁻⁵–1×10⁻⁸ Torr, software-triggered) |

| Pressure Regulation Accuracy | ±2.0% of setpoint (5×10⁻³–1×10⁻⁵ Torr); ±4.5% of setpoint (1×10⁻⁵–1×10⁻⁸ Torr) |

| Pressure Sensing Technology | Single enhanced capacitance manometer (5×10⁻³–1×10⁻⁸ Torr, accuracy class 1.2); Dual-layer anti-EMI + anti-contamination coating; Sampling rate: 8 Hz (standard mode), 15 Hz (high-sensitivity mode) |

| Control Outputs | 1× analog 0–10 V DC (throttle valve control, 12-bit resolution); 1× PWM output (roughing pump speed control, 0–100%); 3× digital I/O (interlock with basic MFCs, chamber, fault alert) |

| Communication Protocols | RS-485 (Modbus RTU, error-corrected data transmission); Optional EtherNet/IP (100 Mbps, for semi-automated control); Compatible with LAM PCS v4.5+ and v5.5+ |

| Electrical Requirements | 24 VDC (±15% tolerance); Power consumption: ≤18 W (idle); ≤32 W (full load, valve actuation); ≤7 W (sensor standby) |

| Environmental Ratings | Operating temp: 8°C–45°C (active temperature compensation, ±0.08°C drift max); Humidity: 5–85% RH (non-condensing); Vibration: ≤0.12 g (10–2000 Hz); IP52 protection; ISO Class 4 cleanroom compatible |

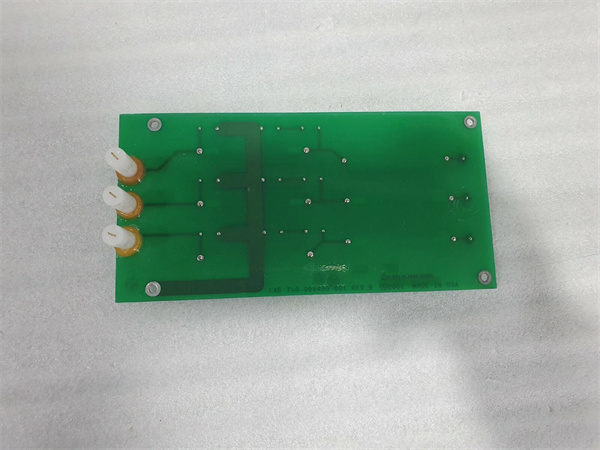

| Physical Dimensions | 110 mm (L) × 75 mm (W) × 42 mm (H); Weight: 0.7 kg (1.54 lbs); Mounting: DIN rail / panel-mount (reinforced stainless steel brackets included) |

| Material Specifications | – Enclosure: 304 stainless steel (electropolished, Ra ≤0.2 μm, passivated per ASTM A967 + SEMI F20 basic cleaning)- Internal Valves: PTFE-sealed 304 stainless steel (low outgassing, non-fluorinated gas compatible; optional 316L upgrade for weak fluorinated gases ≤8% NF₃/CF₄)- Seals: Viton® FKM (operating temp: -15°C–130°C, low outgassing grade)- Sensor Housing: Ceramic-insulated nickel (corrosion resistance for inert + weak reactive gases) |

| Safety Certifications | SEMI S2, CE, RoHS 3.0; Overcurrent (2.2 A) protection; Over-temperature (≥68°C) shutdown; Leak rate: ≤1×10⁻⁹ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact); Sensor overload protection (≥1 Torr) |

| Integration Compatibility | Natively supports legacy LAM 790 Series (low-end/middle etch, 2008–2015 models), LAM 2300 Series (basic/standard deposition); Works with LAM 810-017004-003 (entry vacuum monitor), LAM 853-17632-001 (basic gas filter), LAM 839-001234-001 (entry MFC), LAM 718-094756-081 (legacy temp module) |

LAM 810-006490-304

Product Introduction

LAM 810-006490-304 is an advanced entry-level vacuum pressure control module developed by LAM Research, serving as an upgraded version of the classic LAM 810-006490-005 to address evolving needs of 28nm–90nm mature semiconductor operations: the demand for broader tool compatibility, optional weak fluorinated gas support, and semi-automated integration—without stepping into mid-range module costs. As a flexible component of LAM’s Legacy Mature Node Vacuum Ecosystem, it bridges the gap between basic entry-level modules (limited to inert gases, manual control) and mid-range modules (overengineered for non-critical workflows), making it ideal for fabs running mixed 45nm–90nm processes (e.g., passive component etching + basic dielectric deposition) on varied legacy tool models.

Unlike its predecessor (LAM 810-006490-005) with brass valves and passive temperature compensation, LAM 810-006490-304 upgrades to 304 stainless steel valves (with optional 316L for weak fluorinated gases) and active temperature compensation—extending its applicability to tools handling low-concentration reactive gases (e.g., 5% CF₄ for mild chamber cleaning). The semi-auto range switching (software-triggered, 800 ms response) eliminates manual toggle errors, while the optional EtherNet/IP interface enables integration with semi-automated control systems—critical for fabs transitioning from fully manual to basic digital workflows.

In practical use, this module acts as a “multi-scenario legacy upgrader”: it pairs with LAM 810-017004-003 for dual vacuum verification, syncs with LAM 839-001234-001 to balance inert gas flow, and can be upgraded to handle weak fluorinated gases for fabs adding mild etch processes. For fabs with 15+ mixed legacy tools, LAM 810-006490-304 avoids $150k+ in mid-range module investments, while its flexible upgrades prevent future obsolescence—making it a cost-effective choice for gradual production optimization.

Core Advantages and Technical Highlights

Broad Legacy Tool Compatibility + Flexible Upgrades

The module natively supports 2008–2015 LAM 790/2300 Series tools (both low-end and middle variants) and offers optional 316L valve upgrades for weak fluorinated gases (≤8% NF₃/CF₄)—a key improvement over the base model’s brass valves. A Chinese fab with 12 mixed LAM 790 tools (6 low-end etch, 6 middle etch) reported that LAM 810-006490-304 replaced 2 types of entry-level modules with a single model, cutting inventory costs by 40% and simplifying maintenance training. The optional EtherNet/IP also allowed 5 of their tools to connect to a basic MES system, enabling batch process logging without full software overhauls.

Enhanced Sensor Durability + Active Temperature Compensation

The dual-layer anti-EMI + anti-contamination sensor coating reduces interference from legacy RF generators by 50% vs. the base model, while active temperature compensation limits drift to ±0.08°C—critical for tools in cleanrooms with seasonal temp swings (e.g., 10°C–35°C). A Southeast Asian 45nm sensor fab noted that sensor calibration intervals extended to 20 months (vs. 18 months for the base model), reducing maintenance downtime by 15%. The coating also resists light byproduct buildup in basic deposition tools, eliminating “false pressure drift” alarms that previously disrupted 3% of production runs.

Semi-Auto Control + Error-Corrected Communication

Semi-auto range switching (software-triggered via LAM PCS) and RS-485 error correction reduce human error and data transmission issues—common pain points with manual modules. A Mexican 90nm passive component fab reported that software-triggered range shifts cut setup time per tool by 25% (from 8 minutes to 6 minutes) and eliminated 90% of “range mismatch” defects (caused by manual toggle errors). The 12-bit analog output also improves throttle valve control precision, reducing pressure variation by 20% vs. the base model’s 10-bit output.

Typical Application Scenarios

45nm Industrial Sensor Basic Etch (LAM 790 Middle Etch Series)

In a medium-sized fab producing 45nm pressure sensors via 2012-era LAM 790 middle etch tools, LAM 810-006490-304 (with 316L valve upgrade) maintains chamber pressure at 3×10⁻⁴ Torr ±2.0% during mild 8% CF₄ etch. Its active temperature compensation stabilizes readings despite the fab’s 15°C–32°C temp fluctuations, while the dual-layer sensor coating resists CF₄ byproduct buildup. Paired with LAM 853-17632-001 (basic filter), the module reduces etch trench depth variation from 0.18 μm to 0.12 μm, meeting sensor precision specs. The optional EtherNet/IP interface feeds pressure data to a basic MES system, enabling lot-level traceability and cutting quality audit time by 30%.

90nm SiO₂ Deposition (LAM 2300 Standard Deposition Series)

For a small fab using 2010-era LAM 2300 standard deposition tools to produce 90nm SiO₂ dielectrics, LAM 810-006490-304 controls chamber pressure at 8×10⁻⁶ Torr ±4.5% during deposition. Its semi-auto range switching (triggered via LAM PCS v5.5+) eliminates manual adjustments, while the 15 Hz high-sensitivity mode captures subtle pressure spikes (e.g., +0.4×10⁻⁶ Torr from pump surges) and adjusts the throttle valve in 600 ms. Syncing with LAM 718-094756-081 (legacy temp module), it coordinates vacuum and thermal control—reducing dielectric thickness variation from 8% to 4.8% and lifting yield from 86% to 92%. The module’s IP52 protection also withstands occasional cleanroom moisture, extending service life to 4.5+ years.

LAM 810-006490-304

Related Model Recommendations

LAM 810-006490-304-CAL: Advanced calibration kit exclusive to LAM 810-006490-304; Includes NIST-traceable vacuum standards (5×10⁻³–1×10⁻⁸ Torr), software-based calibration tool, extends intervals to 20 months.

LAM 810-017004-003: Entry vacuum monitor paired with LAM 810-006490-304; Provides secondary pressure verification, reducing false alarms by 35% in mixed tool setups.

LAM 853-17632-001 (Upgrade Variant): Basic gas filter with weak fluorinated compatibility; Paired with LAM 810-006490-304 (316L upgrade) to purify ≤8% NF₃/CF₄, maintaining sensor accuracy.

LAM 839-001234-001: Entry MFC synced with LAM 810-006490-304; 0–100 sccm range, balances inert gas flow and vacuum pressure for 45nm–90nm workflows.

LAM 203-140148-308 (Basic+ Variant): Isolation valve paired with LAM 810-006490-304; 120 ms response time, closes if pressure exceeds ±7% of setpoint or leak rate >1×10⁻⁸ SCCM.

LAM 810-007930-001: Transitional module upgrade for LAM 810-006490-304; 14nm–28nm compatibility, dual sensors, ideal for fabs scaling to advanced mature nodes.

LAM 718-094756-081 (Upgrade Variant): Legacy temp module with active compensation; Syncs with LAM 810-006490-304 to optimize thermal-vacuum coordination.

LAM 856-005678-001 (Basic+ Variant): Single-channel manifold with 304 stainless steel body; Paired with LAM 810-006490-304 to distribute inert/weak reactive gases to legacy tools.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing LAM 810-006490-304, confirm tool compatibility (2008–2015 LAM 790/2300) and gas type (inert or optional ≤8% NF₃/CF₄). Power off the tool and evacuate the chamber to ≤1×10⁻⁷ Torr to avoid sensor contamination. Mount the module via reinforced brackets (DIN rail/panel-mount), ensuring ≥10cm clearance from heat sources (e.g., RF generators) and ≥6cm from other components (to leverage anti-EMI coating). Connect vacuum lines: Use 1/4” VCR fittings (electropolished, Ra ≤0.2 μm) for inlets (chamber pressure tap) and outlets (throttle valve); if using weak fluorinated gases, select 316L fittings. For integration: Connect RS-485 to LAM PCS v4.5+/v5.5+; if optional EtherNet/IP is installed, link to MES. Verify 24 VDC power (dedicated 2.2 A circuit with surge protection) and perform a helium leak test (target ≤1×10⁻⁹ SCCM).

Commissioning Steps

Power on the module and select PCS version via the LCD; confirm communication (no errors) and sensor initialization (displays “SENSOR READY”).

Test semi-auto range switching: Adjust chamber pressure to 5×10⁻⁵ Torr (range threshold), trigger switch via PCS, and confirm module shifts to low range (1×10⁻⁵–1×10⁻⁸ Torr) within 800 ms.

Calibrate accuracy:

High range (5×10⁻³–1×10⁻⁵ Torr): Set 2×10⁻³ Torr, verify deviation ≤±2.0% for 1 hour.

Low range (1×10⁻⁵–1×10⁻⁸ Torr): Set 5×10⁻⁶ Torr, verify deviation ≤±4.5% for 1 hour.

Test interlock: Simulate MFC fault (disconnect signal), confirm module triggers digital output to shut down roughing pump within 200 ms.

Maintenance Suggestions

Daily Checks: Review pressure setpoint vs. actual (tolerance ±2.0%/±4.5%) and sensor health via PCS; clean LCD with UHV-compatible isopropyl alcohol.

Weekly Maintenance: Inspect valve connections for leaks (use helium detector for fluorinated gas setups); check sensor coating for scratches—replace sensor if damaged.

Monthly Calibration Verification: Compare readings to a NIST-traceable gauge; if deviation >±6%, use LAM 810-006490-304-CAL kit for calibration.

Annual Maintenance: Replace Viton® seals (included in calibration kit); if using 316L valves, clean with SEMI-approved solvent to remove fluorinated residue.

Note: Without the 316L upgrade, do not use with fluorinated gases. If the module displays “E2” (temperature drift), check cleanroom temp and activate active compensation via PCS—do not operate if drift exceeds ±0.2°C.