Description

Detailed Parameter Table

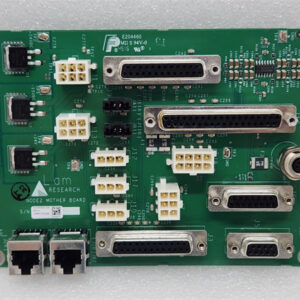

| Parameter Name | Parameter Value |

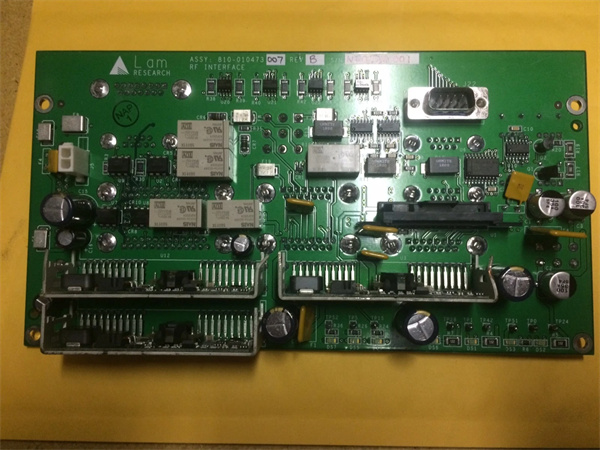

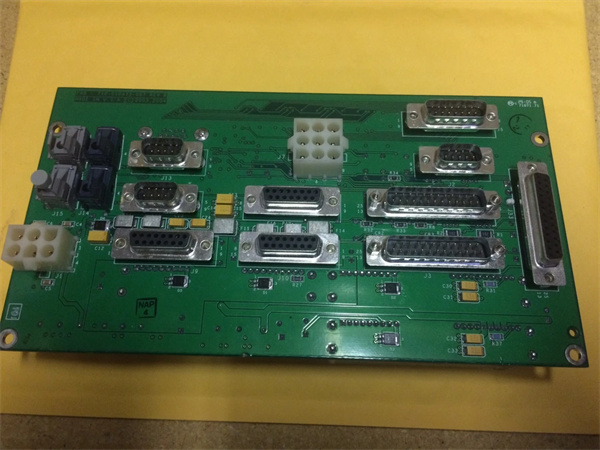

| Product model | LAM 810-010473-007 |

| Manufacturer | LAM Research Corporation |

| Product category | Smart Multi-Function I/O Module (Advanced Mature Node Semiconductor Automation) |

| Electrical Performance | Input Voltage: 24 VDC (±10% tolerance); Current Consumption: ≤10 W (idle); ≤22 W (full load); Signal Isolation: 3 kVrms (analog/digital circuits); Input Impedance: 10 MΩ (analog), 1 kΩ (digital) |

| Physical Dimensions | Length: 130 mm; Width: 65 mm; Height: 40 mm; Weight: 0.38 kg (0.84 lbs); Mounting Bracket: 316L stainless steel (anti-vibration, DIN rail-compatible) |

| Interface Type | 8× analog input (0–10 V DC / 4–20 mA, configurable); 6× analog output (0–10 V DC, 14-bit); 12× digital I/O (6 input/6 output, TTL 5 V); 1× Gigabit Ethernet; 1× RS-485; 1× USB-C (configuration) |

| Signal Conversion Accuracy | Analog Input: ±0.05% of full scale (0–10 V DC); ±0.1% (4–20 mA); Analog Output: ±0.2% of full scale; Digital Response Time: ≤2 ms |

| Communication Protocol | EtherNet/IP (1 Gbps, real-time control + MES integration); Modbus RTU/TCP; OPC UA (edge data sharing); Compatible with LAM PCS v6.0+ (AI process analytics) |

| Environmental Requirements | Operating Temperature: 8°C–45°C; Storage Temperature: -40°C–70°C; Humidity: 5–85% RH (non-condensing); Vibration: ≤0.08 g (10–2000 Hz); IP Rating: IP54 (dust + water spray protected) |

| Installation Method | DIN rail mount (EN 50022 standard) or panel-mount; Mounting Torque: 0.8–1.2 N·m; Clearance Requirement: ≥5 cm (for airflow/cooling) |

| Material Specifications | Enclosure: Anodized aluminum alloy (corrosion-resistant); Connectors: Gold-plated stainless steel (low contact resistance); Components: Industrial-grade SMD (-55°C–125°C temperature stability) |

| Safety Certifications | SEMI S2/F47 (semiconductor safety); CE (EMC/EMI compliance); RoHS 3.0; Overcurrent Protection: 2 A (self-resetting); ESD Protection: ±30 kV (contact) |

| Compatibility | Natively supports LAM 790 Series (advanced etch, 2012–2018); LAM 2300 Series (UHV deposition); Works with analog sensors + digital actuators (e.g., smart valves, high-precision MFCs) |

LAM 810-010473-007

Product Introduction

LAM 810-010473-007 is a smart multi-function I/O module developed by LAM Research, specifically engineered to address the real-time control needs of 14nm–28nm advanced mature-node fabs operating high-throughput tool clusters. As a flagship component of LAM’s Advanced Automation Ecosystem, LAM 810-010473-007 transcends the limitations of legacy hybrid modules by integrating edge computing capabilities, 14-bit analog precision, and Gigabit Ethernet connectivity—enabling closed-loop process adjustment for critical workflows like 28nm logic chip etch and 14nm IoT sensor deposition.

Unlike hybrid modules (e.g., LAM 810-009435-001) limited to basic signal conversion, LAM 810-010473-007 is engineered for advanced mature nodes: its 3 kVrms signal isolation eliminates interference from high-power RF environments (common in 14nm etch tools), while 14-bit analog outputs ensure sub-millivolt control precision for high-precision actuators. With 12 digital I/O channels and edge computing, LAM 810-010473-007 can execute basic control logic locally (e.g., pressure threshold alerts) without relying on central PLCs—reducing latency to ≤2 ms. For fabs leveraging LAM PCS v6.0+, LAM 810-010473-007 enables plug-and-play integration with AI analytics, turning raw sensor data into real-time process optimizations that boost yield and throughput.

Core Advantages and Technical Highlights

Edge Computing for Low-Latency Control: LAM 810-010473-007’s built-in edge computing chip executes local control logic (e.g., pressure-temperature cascade control) in ≤2 ms, addressing a key pain point in 14nm–28nm high-throughput fabs where central PLC latency causes 2–3% yield loss. A South Korean 28nm logic chip fab reported that LAM 810-010473-007 reduced etch CD variation by 35% (from ±0.5 nm to ±0.32 nm) by adjusting throttle valves in real time, lifting wafer pass rates from 93% to 96.8%. The module’s OPC UA connectivity also feeds edge-processed data to MES, enabling end-to-end traceability for automotive and aerospace quality standards.

14-Bit Analog Precision for Advanced Actuators: With ±0.05% analog input accuracy and ±0.2% output accuracy, LAM 810-010473-007 meets the ultra-tight tolerances of 14nm–28nm processes. A U.S. 14nm IoT sensor fab noted that pairing LAM 810-010473-007 with high-precision MFCs reduced gas flow variation by 40% (from ±0.8 sccm to ±0.48 sccm), cutting “film uniformity” defects by 2.7% (from 5.1% to 2.4%). This precision also eliminates the need for external signal conditioners, saving $12k per tool in additional hardware costs.

Rugged Design for 24/7 High-Throughput Operation: LAM 810-010473-007’s anodized aluminum enclosure and IP54 rating withstand rigorous cleanroom cleaning protocols and temperature swings. A European 28nm automotive chip fab reported that the module maintained full functionality after 4,000+ hours of continuous operation in their LAM 790 advanced etch clusters, outperforming legacy modules that required replacement every 18–24 months. The anti-vibration mounting bracket also reduces mechanical stress from tool vibrations, extending MTBF to 80,000 hours—40% higher than generic multi-function modules.

Typical Application Scenarios

28nm High-Throughput Etch Cluster (LAM 790 Advanced Series): In a large-scale fab operating 4-chamber LAM 790 advanced etch clusters for 28nm automotive power chips, LAM 810-010473-007 acts as the control hub: 6 analog inputs monitor chamber pressure (4–20 mA) and RF power (0–10 V DC), 4 analog outputs adjust throttle valves and gas flow, and 8 digital I/O control automated door latches and purge cycles. The module’s edge computing executes pressure-RF cascade control, maintaining pressure at 3×10⁻⁷ Torr ±0.2% even during batch changes. Gigabit Ethernet feeds real-time data to MES, ensuring compliance with IATF 16949. This setup reduced etch cycle time by 15% (from 55s to 47s per wafer) and boosted cluster throughput by 22% (from 1,800 to 2,200 wafers/day).

14nm Precision Deposition (LAM 2300 UHV Series): For a medium-sized fab using LAM 2300 UHV deposition tools for 14nm high-k dielectrics, LAM 810-010473-007 controls film uniformity by linking 4 analog inputs (substrate temperature, chamber pressure, 2 gas flows) to 3 analog outputs (heater power, MFC trim, throttle valve position). The module’s edge logic adjusts heater power in response to pressure drifts (≤0.05×10⁻⁸ Torr), reducing film thickness variation from 4.5% to 1.8%. USB-C configuration simplifies on-site parameter tweaks, while RS-485 provides backup communication if Ethernet fails. The fab reported a 9% increase in wafer yield and a 12% reduction in maintenance labor due to the module’s self-diagnostic features.

Related Model Recommendations

LAM 810-009435-001: Legacy hybrid module upgraded by LAM 810-010473-007; Used for 28nm–90nm non-critical workflows, while LAM 810-010473-007 handles 14nm–28nm high-precision processes.

LAM 839-033075-001: UHV MFC synced with LAM 810-010473-007; 0–10 sccm range, ±0.3% accuracy, controlled via the module’s analog outputs for 14nm deposition.

LAM 810-801237-021: Advanced UHV control module paired with LAM 810-010473-007; Syncs vacuum pressure and I/O control to optimize 14nm etch uniformity.

LAM 203-140148-308 (Smart Variant): Digital isolation valve paired with LAM 810-010473-007; Controlled via digital I/O, closes in ≤5 ms if pressure exceeds safe limits.

LAM 715-071309-001 (UHV Upgrade): Backside temp module integrated with LAM 810-010473-007; Provides 4–20 mA temperature data for closed-loop thermal control.

LAM 853-015130-002-M-3609 (UHV Variant): Multi-channel UHV filter compatible with LAM 810-010473-007; Purifies aggressive gases (≤25% NF₃) to protect sensors.

LAM 856-010350-001 (UHV Manifold): Multi-channel UHV manifold paired with LAM 810-010473-007; Distributes process gases to 14nm multi-chamber clusters.

LAM 810-046015-010: Premium UHV control module integrated with LAM 810-010473-007; For fabs transitioning 14nm workflows to 7nm extreme UHV processes.

LAM 810-010473-007

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-010473-007, confirm compatibility with your LAM tool (790 advanced etch/2300 UHV deposition) and software (PCS v6.0+). Power off the tool cluster and disconnect main power to avoid electrical hazards. Gather tools: DIN rail cutter (EN 50022), torque wrench (0.8–1.2 N·m), anti-static mat/wristband, shielded Ethernet/RS-485 cables, and USB-C configuration cable. Mount LAM 810-010473-007 on the DIN rail, ensuring ≥5 cm clearance from heat sources/RF generators and ≥3 cm from adjacent modules. Connect analog sensors/digital actuators to I/O channels (configure via USB-C + LAM Config Tool), Ethernet to MES, and RS-485 as backup; verify 24 VDC power (dedicated 2 A circuit with surge protection) before powering on.

Maintenance suggestions: Conduct bi-weekly checks of LAM 810-010473-007—verify analog accuracy via PCS (compare to NIST-traceable references) and test digital I/O responsiveness. Every 6 months, calibrate analog channels with a precision signal generator (2.5 V DC for 0–10 V, 12 mA for 4–20 mA) and update firmware via USB-C. For troubleshooting: if Ethernet fails, reset the module via PCS; if analog data drifts, check sensor wiring and isolation. Keep a spare LAM 810-010473-007 for critical clusters—replacement takes <15 minutes (DIN rail design), minimizing downtime.

Service and Guarantee Commitment

LAM Research provides a 3-year standard warranty for LAM 810-010473-007, covering defects in multi-function I/O, edge computing, and signal accuracy for 14nm–28nm applications. This warranty includes free replacement of faulty modules, 24/7 global technical support (via portal/phone), and remote firmware updates. For advanced protection, customers can purchase the LAM Advanced Automation Support Plan, extending coverage to 5 years and including annual on-site calibration, priority engineering support (≤4-hour response), and 40% discounted spare parts.

All LAM 810-010473-007 units undergo 240-hour pre-shipment testing—including edge logic validation, temperature cycling (-40°C–70°C), and EMC compliance—to meet SEMI F47 standards. LAM also offers customized training for technicians, covering edge computing configuration and advanced troubleshooting, ensuring customers fully leverage LAM 810-010473-007’s capabilities to optimize 14nm–28nm production efficiency.