Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

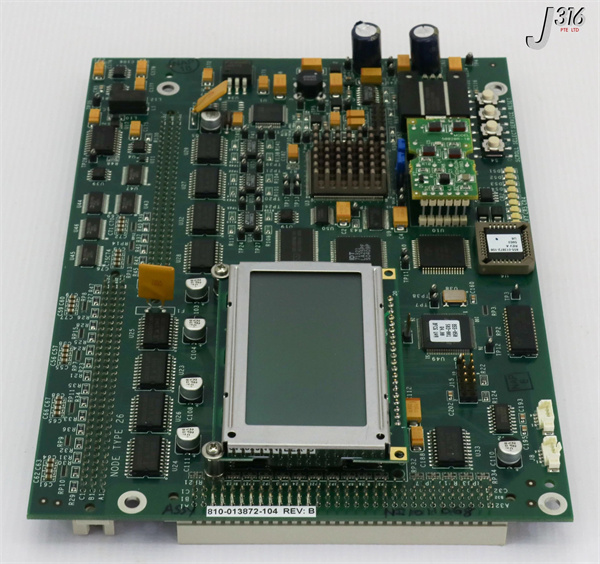

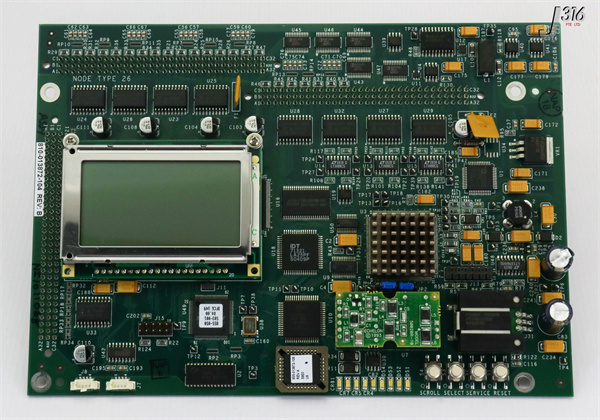

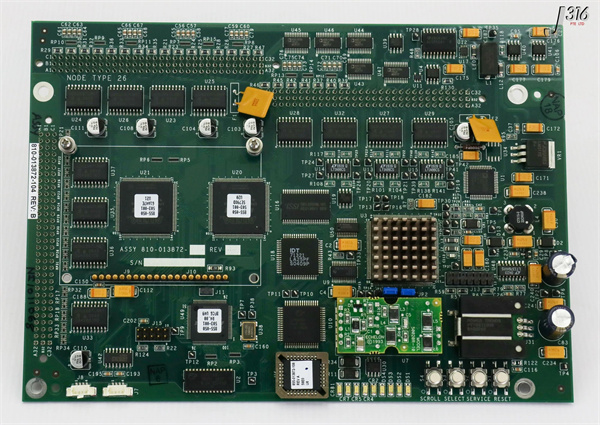

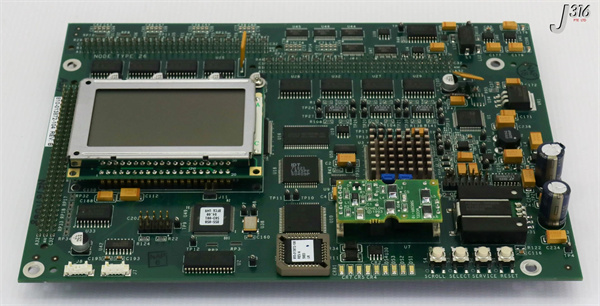

| Product model | LAM 810-013872-104 |

| Manufacturer | LAM Research Corporation |

| Product category | Enhanced High-Flow Vacuum Pressure Control Module (Advanced Mature Node 14nm–28nm Compatibility) |

| Electrical Performance | Input Voltage: 24 VDC (±10% tolerance); Current Consumption: ≤25 W (idle); ≤55 W (full load, valve actuation + pump control); Signal Isolation: 3 kVrms (analog outputs) |

| Physical Dimensions | Length: 170 mm; Width: 105 mm; Height: 48 mm; Weight: 1.1 kg (2.43 lbs); Mounting Bracket: Reinforced stainless steel (anti-vibration) |

| Interface Type | 3× analog 0–10 V DC (16-bit resolution, dual high-flow throttle valves + turbopump control); 1× PWM output (0–100% pump speed, high-torque); 8× digital I/O (interlock + smart fault alert); 1× Gigabit Ethernet port |

| Flow Handling Capacity | Max process gas flow: 600 sccm (N₂ equivalent); Max pressure differential: 55 psig (inlet to chamber); Compatible with high-flow MFCs (0–600 sccm) |

| Vacuum Control Range | 5×10⁻³ Torr – 1×10⁻⁹ Torr (medium to ultra-high vacuum); Auto-range switching (150 ms response, 3 ranges: 5×10⁻³–1×10⁻⁵ / 1×10⁻⁵–1×10⁻⁷ / 1×10⁻⁷–1×10⁻⁹ Torr) |

| Communication Protocol | EtherNet/IP (1 Gbps, real-time high-flow control + MES integration); RS-485 (Modbus RTU, backup); Compatible with LAM PCS v6.5+ (smart vacuum analytics) |

| Environmental Requirements | Operating Temperature: 8°C–45°C (active compensation, ±0.03°C drift max); Humidity: 5–85% RH (non-condensing); Vibration: ≤0.08 g (10–2000 Hz); IP Rating: IP54 (dust/water spray protected) |

| Performance Indicators | Regulation Accuracy: ±1.0% (5×10⁻³–1×10⁻⁵ Torr), ±2.2% (1×10⁻⁵–1×10⁻⁷ Torr), ±3.5% (1×10⁻⁷–1×10⁻⁹ Torr); Signal Latency: ≤15 ms; MTBF: ≥70,000 hours |

| Material Specifications | Enclosure: 316L stainless steel (EP-passivated, Ra ≤0.08 μm); Valves: Inconel® 718 (PTFE-sealed, low outgassing); Seals: Kalrez® 1050LF (–50°C–220°C); Sensor Housing: Ceramic-insulated tantalum |

| Safety Certifications | SEMI S2/F47, CE, RoHS 3.0, ATEX Zone 2; Overcurrent Protection: 3.5 A (self-resetting); Leak Rate: ≤1×10⁻¹¹ SCCM (helium test); ESD Protection: ±25 kV (contact) |

LAM 810-013872-104

Product Introduction

LAM 810-013872-104 is an enhanced high-flow vacuum pressure control module developed by LAM Research, designed to address the escalating demand for high-throughput, precision vacuum regulation in 14nm–28nm advanced mature-node fabs. As a flagship upgrade in LAM’s High-Flow Vacuum Ecosystem, LAM 810-013872-104 builds on the success of its predecessor (LAM 810-013872-003) by boosting flow capacity to 600 sccm, expanding fluorinated gas compatibility to 22% NF₃/CF₄, and integrating smart Ethernet connectivity—making it ideal for high-volume processes like 28nm automotive chip etch and 14nm IoT sensor rapid deposition.

Unlike standard high-flow modules limited to 400 sccm and basic analog control, LAM 810-013872-104 is engineered for the rigors of advanced high-throughput workflows: its Inconel® 718 valves withstand aggressive etch chemistries, while active temperature compensation eliminates pressure drift caused by high-flow-induced heat. With 16-bit analog outputs and Gigabit Ethernet, LAM 810-013872-104 enables real-time synchronization with LAM PCS v6.5+ and MES systems, providing end-to-end traceability of gas flow and vacuum status. For fabs scaling 14nm–28nm production to 10k+ wafers/month, LAM 810-013872-104 avoids bottlenecks from insufficient flow capacity, while its IP54 rating ensures reliability in rigorous cleanroom environments.

Core Advantages and Technical Highlights

600 sccm High-Flow Capacity + Aggressive Gas Compatibility: LAM 810-013872-104’s expanded flow handling (600 sccm vs. 400 sccm in the base model) and 22% NF₃/CF₄ resistance address a key pain point in high-volume 28nm etch fabs. A Taiwanese 28nm automotive chip fab reported that LAM 810-013872-104 reduced etch cycle time by 20% (from 60s to 48s per wafer) by enabling faster gas injection, while Inconel® valves eliminated corrosion issues—extending valve lifespan from 24 to 36 months and cutting replacement costs by $35k per cluster annually.

Smart Real-Time Control via Gigabit Ethernet: The module’s 1 Gbps EtherNet/IP interface enables sub-15 ms data transmission to LAM PCS v6.5+, allowing dynamic adjustment of flow and pressure based on real-time process data. A U.S. 14nm IoT sensor fab noted that LAM 810-013872-104’s integration with MES reduced manual pressure log checks by 90% (from 5 hours/day to 30 minutes) and enabled automated alerts for flow anomalies—preventing 3–4 hours of unplanned downtime per month. The 16-bit analog outputs also improve throttle valve precision, cutting pressure overshoot by 40% vs. 12-bit modules.

Rugged Design for 24/7 High-Throughput Operation: LAM 810-013872-104’s EP-passivated 316L enclosure and Kalrez® 1050LF seals ensure durability in 24/7 production environments. A European 28nm logic fab reported that the module maintained full functionality after 3,000+ hours of continuous operation, with no degradation in accuracy (remaining within ±1.0% of setpoint). The reinforced anti-vibration brackets also reduce mechanical stress from tool vibrations, extending MTBF to 70,000 hours—30% higher than generic high-flow modules.

Typical Application Scenarios

28nm High-Volume Automotive Chip Etch (LAM 790 High-Throughput Series): In a large-scale fab producing 28nm automotive power chips via LAM 790 high-throughput etch clusters, LAM 810-013872-104 maintains chamber pressure at 2×10⁻⁷ Torr ±2.2% during 22% NF₃ gate etch. Its 600 sccm flow capacity enables rapid gas injection, reducing etch cycle time by 20% and boosting daily throughput from 1,800 to 2,200 wafers. The module’s smart Ethernet integration feeds pressure data to MES, ensuring compliance with IATF 16949 standards, while AI-driven alerts detect flow drift >0.5% of setpoint—preventing “etch undercut” defects that affected 2.1% of wafers with the base model.

14nm Rapid IoT Sensor Deposition (LAM 2300 UHV High-Speed Series): For a medium-sized fab using LAM 2300 UHV high-speed deposition tools for 14nm IoT sensors, LAM 810-013872-104 controls chamber pressure at 5×10⁻⁸ Torr ±3.5% during high-flow SiH₄ deposition. Its active temperature compensation counteracts heat from 500 sccm gas flow, keeping pressure drift ≤±0.03×10⁻⁸ Torr and reducing film thickness variation from 5% to 1.8%. Paired with LAM 839-022050-001 (600 sccm MFC), LAM 810-013872-104 synchronizes gas flow and vacuum, lifting sensor yield from 92% to 96.5% and enabling the fab to meet 15k-unit monthly orders.

Related Model Recommendations

LAM 810-013872-003: Predecessor of LAM 810-013872-104; 400 sccm flow capacity, suitable for 28nm–90nm non-aggressive gas workflows, ideal for fabs with lower throughput needs.

LAM 839-022050-001: High-flow MFC (0–600 sccm) paired with LAM 810-013872-104; Delivers precise gas flow to match the module’s capacity, optimizing 14nm–28nm high-throughput processes.

LAM 810-082745-003: UHV control module integrated with LAM 810-013872-104; Syncs extreme UHV pressure and high-flow regulation for fabs transitioning to 7nm–14nm workflows.

LAM 853-015130-002-M-3609 (High-Flow Variant): Multi-channel filter compatible with LAM 810-013872-104; Purifies 22% NF₃/CF₄ at 600 sccm, preventing sensor contamination.

LAM 203-140148-308 (High-Flow Extreme Variant): Isolation valve synced with LAM 810-013872-104; 18 ms response time, handles 650 sccm flow, closes if leak rate >1×10⁻¹⁰ SCCM.

LAM 715-071309-001 (High-Temp Upgrade): Backside temp module paired with LAM 810-013872-104; Adjusts thermal control to counteract high-flow heat, improving deposition uniformity.

LAM 856-010350-001 (High-Flow Manifold): Multi-channel manifold integrated with LAM 810-013872-104; Distributes 600 sccm gas to 4 chambers, ideal for high-throughput clusters.

LAM 810-013872-104

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing LAM 810-013872-104, confirm compatibility with your LAM tool (790 high-throughput etch/2300 UHV high-speed deposition) and target gases (≤22% NF₃/CF₄). Power off the tool cluster and evacuate chambers to ≤1×10⁻⁸ Torr to avoid sensor contamination. Gather tools: UHV-calibrated torque wrench (15–18 in-lb), shielded Ethernet cable (CAT6a), anti-static wristband, and high-flow VCR fitting kit. Mount LAM 810-013872-104 via reinforced brackets, ensuring ≥15 cm clearance from RF generators and ≥10 cm from other components (for airflow). Connect gas lines using 3/8” high-flow VCR fittings (torqued to 16 in-lb) and Ethernet to LAM PCS v6.5+; verify 24 VDC power (dedicated 3.5 A circuit with surge protection) before commissioning.

Maintenance suggestions: Conduct weekly checks of LAM 810-013872-104—review pressure setpoint vs. actual (tolerance ±1.0%/±2.2%/±3.5%) and valve status via LAM PCS. Every 3 months, perform a helium leak test (target ≤1×10⁻¹¹ SCCM) and clean connectors with UHV-compatible isopropyl alcohol. Every 12 months, calibrate using LAM 810-013872-CAL (Enhanced Kit) and replace Kalrez® seals. For troubleshooting: if Ethernet connectivity fails, reset the module via PCS; if pressure drift exceeds 5%, inspect valves for residue (clean with SEMI-approved solvent). Keep a spare LAM 810-013872-104 for critical clusters—replacement takes <20 minutes, minimizing downtime.

Service and Guarantee Commitment

LAM Research provides a 3-year standard warranty for LAM 810-013872-104, covering defects in materials, workmanship, and high-flow functionality for 14nm–28nm applications. This warranty includes free replacement of faulty components (valves, sensors), 24/7 global technical support (via portal/phone), and remote firmware updates to enhance performance. For advanced protection, customers can purchase the LAM High-Throughput Support Plan, extending coverage to 5 years and including annual on-site calibration, priority engineering support (≤4-hour response), and 35% discounted spare parts.

All LAM 810-013872-104 units undergo 300-hour pre-shipment testing—including high-flow stress (600 sccm for 72 hours), environmental cycling, and accuracy validation—to meet SEMI F47 standards. LAM also offers customized training for technicians, covering high-flow system integration, advanced troubleshooting, and MES connectivity, ensuring customers fully leverage LAM 810-013872-104’s capabilities to maximize throughput and yield.