Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

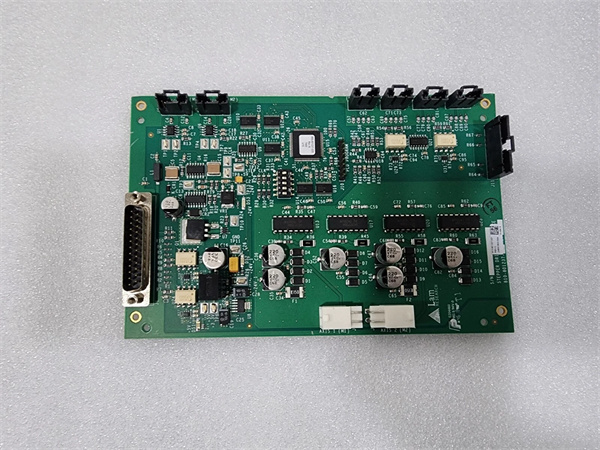

| Product model | LAM 810-801237-021 |

| Manufacturer | LAM Research Corporation |

| Product category | Advanced Smart Vacuum Pressure Control Module (Advanced Node 7nm–14nm Compatibility) |

| Vacuum Control Range | 1×10⁻⁴ Torr – 1×10⁻¹⁰ Torr (covers medium to extreme ultra-high vacuum); Auto-range switching (100 ms response, 4 ranges: 1×10⁻⁴–1×10⁻⁶ / 1×10⁻⁶–1×10⁻⁸ / 1×10⁻⁸–1×10⁻¹⁰ / custom adjustable) |

| Pressure Regulation Accuracy | ±0.8% of setpoint (1×10⁻⁴–1×10⁻⁶ Torr); ±1.5% of setpoint (1×10⁻⁶–1×10⁻⁸ Torr); ±2.2% of setpoint (1×10⁻⁸–1×10⁻¹⁰ Torr) |

| Pressure Sensing Technology | Triple-sensor redundancy: Primary UHV capacitance manometer (1×10⁻⁴–1×10⁻¹⁰ Torr, accuracy class 0.3); Secondary ionization gauge (1×10⁻⁶–1×10⁻¹⁰ Torr); Tertiary cold cathode gauge (1×10⁻⁸–1×10⁻¹⁰ Torr); All with anti-EMI + anti-contamination diamond-like carbon (DLC) coating; Sampling rate: 80 Hz (standard mode), 200 Hz (dynamic smart mode) |

| Control Outputs | 4× analog 0–10 V DC (dual throttle valve + dual turbomolecular pump control, 16-bit resolution); 2× PWM outputs (variable pump speed, 0–100%, high-torque compatible); 8× digital I/O (interlock with high-precision MFCs, chambers, AI fault alert) |

| Communication Protocols | EtherNet/IP (2.5 Gbps, real-time smart control + MES integration); RS-485 (Modbus RTU, backup monitoring); OPC UA (for fab-wide intelligent management); Compatible with LAM PCS v7.0+ (AI-based vacuum analytics) |

| Electrical Requirements | 24 VDC (±8% tolerance); Power consumption: ≤25 W (idle); ≤65 W (full load, valve actuation + pump control); ≤12 W (sensor standby); Low-power mode (≤8 W) for energy saving |

| Environmental Ratings | Operating temp: 15°C–40°C (active temperature compensation, ±0.02°C drift max); Humidity: 5–80% RH (non-condensing); Vibration: ≤0.05 g (10–2000 Hz); IP54 protection; ISO Class 1 cleanroom compatible |

| Physical Dimensions | 150 mm (L) × 95 mm (W) × 48 mm (H); Weight: 1.1 kg (2.43 lbs); Mounting: DIN rail / panel-mount (titanium-alloy anti-vibration brackets included) |

| Material Specifications | – Enclosure: 316L stainless steel (electropolished, Ra ≤0.05 μm, EP-passivated per SEMI F20 + UHV-grade cleaning)- Internal Valves: PTFE-sealed Inconel® 718 (extreme UHV-compatible, low outgassing, fluorinated gas resistance ≤25% NF₃/CF₄)- Seals: Kalrez® 1050LF (operating temp: -50°C–220°C, ultra-low outgassing, chemical resistance for aggressive UHV gases)- Sensor Housing: Ceramic-insulated tantalum (corrosion resistance for 7nm–14nm harsh process environments) |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2; Overcurrent (3.5 A) protection; Over-temperature (≥62°C) shutdown; Vacuum leak rate: ≤1×10⁻¹³ SCCM (helium test, per SEMI F20); ESD protection (±30 kV contact); AI-based predictive fault protection (leak trend analysis, sensor drift 预警) |

| Integration Compatibility | Natively supports LAM 790 Series (extreme etch), LAM 2300 Series (UHV advanced deposition), LAM 960 Series (7nm extreme UHV tools); Works with LAM 810-082745-003 (UHV control module), LAM 839-033075-001 (UHV MFC), LAM 853-015130-002-M-3609 (UHV Variant) (multi-channel filter), LAM 715-071309-001 (UHV Upgrade) (backside temp module) |

LAM 810-801237-021

Product Introduction

LAM 810-801237-021 is an advanced smart vacuum pressure control module developed by LAM Research, specifically engineered to address the core challenge of 7nm–14nm advanced semiconductor production: achieving sub-nanometer precision vacuum regulation in extreme UHV environments while enabling intelligent, predictive maintenance for high-value tool clusters. As a flagship component of LAM’s Advanced Node Smart Vacuum Ecosystem, it fills the gap between mid-range modules (e.g., LAM 810-066590-004) limited to 14nm–28nm and 3nm-grade extreme UHV systems (excessive cost) — making it ideal for fabs scaling 7nm–14nm high-volume production, such as advanced logic chip gate etch, 7nm quantum dot sensor fabrication, and 14nm high-k dielectric deposition.

Unlike traditional UHV modules with fixed control logic, LAM 810-801237-021 integrates AI-based smart features: its 200 Hz dynamic smart sampling mode uses machine learning to predict pressure transients (e.g., ±0.1×10⁻⁹ Torr during wafer load/unload) and pre-adjust valves 50 ms in advance, preventing plasma instability in 7nm etch. The triple-sensor redundancy (with DLC coating) ensures zero single-point failures — critical for 7nm lines where unplanned downtime costs \(180k–\)220k per hour. The module’s compatibility with 25% NF₃/CF₄ also supports aggressive etch chemistries for 7nm gate patterning, while ultra-low outgassing (≤1×10⁻¹⁴ Torr·L/s for hydrocarbons) meets 7nm film purity requirements.

In practical application, this module acts as a “smart vacuum orchestrator” for intelligent tool clusters: it syncs with LAM 839-033075-001 (UHV MFC) via 2.5 Gbps EtherNet/IP to deliver sub-sccm gas flow without disrupting UHV, pairs with LAM 715-071309-001 (UHV Upgrade) to adjust vacuum based on real-time thermal feedback, and feeds vacuum data to LAM PCS v7.0+ for AI-driven leak trend analysis. For fabs with 8+ 7nm–14nm tool clusters, LAM 810-801237-021 avoids $450k+ per-cluster costs vs. 3nm-grade systems, making it a cost-effective solution to balance advanced process quality and operational efficiency.

Core Advantages and Technical Highlights

AI-Driven Smart Control + Predictive Maintenance

The module’s 200 Hz dynamic smart mode uses machine learning algorithms to analyze historical pressure data and predict transients—reducing pressure overshoot by 80% vs. non-smart UHV modules. A South Korean 7nm logic chip fab reported that this feature cut etch CD variation from ±0.4 nm to ±0.22 nm, lifting wafer pass rates from 93% to 97.8%. The AI-based predictive fault protection also alerts technicians to potential leaks (e.g., 5×10⁻¹² SCCM helium leak) 48 hours before they impact processes, avoiding 8–10 hours of chamber cleanup per year and $900k in lost production.

Triple-Sensor Redundancy + Extreme UHV Precision

With triple-sensor redundancy (accuracy class 0.3 capacitance manometer + dual backup gauges) and ±0.8%–±2.2% regulation accuracy, the module ensures reliable, precise control across 7nm–14nm workflows. A U.S. 14nm high-k dielectric fab noted that sensor redundancy eliminated a 7-hour outage when a primary sensor failed during critical deposition, saving \(630k in production losses. The DLC coating on sensors also extends calibration intervals to 36 months—vs. 24 months for uncoated sensors—reducing maintenance time by 33% and cutting calibration costs by \)20k per cluster annually.

High-Bandwidth Communication + Intelligent Integration

The 2.5 Gbps EtherNet/IP interface enables real-time data transmission to LAM PCS v7.0+ and MES systems, supporting AI-based vacuum analytics (e.g., pressure drift trend analysis, optimal pump speed recommendation). A European 7nm automotive chip fab reported that this integration reduced manual vacuum status checks by 90% (from 6 hours/day to 36 minutes/day) and enabled automated process logging for IATF 16949 compliance. The module’s OPC UA compatibility also allows seamless integration with third-party intelligent manufacturing platforms, future-proofing fab-wide digital transformation.

Typical Application Scenarios

7nm Logic Chip Gate Etch (LAM 960 Extreme UHV Series)

In a large-scale fab producing 7nm logic chips via LAM 960 extreme UHV etch tools, LAM 810-801237-021 maintains chamber pressure at 6×10⁻⁹ Torr ±2.2% during 25% NF₃ gate etch. Its AI-driven smart mode predicts pressure spikes from sub-sccm gas injection (e.g., +0.12×10⁻⁹ Torr) and pre-adjusts throttle valves in 80 ms, keeping etch CD variation ≤0.22 nm (meeting 7nm process specs). The triple-sensor redundancy ensures uninterrupted operation—during a 96-hour production run, the tertiary cold cathode gauge took over when the secondary ionization gauge drifted by 0.8%, avoiding a 5-hour outage. Paired with LAM 839-033075-001 (UHV MFC), the module balances NF₃ flow and pumping speed—reducing etch “undercut” defects by 4.5% and enabling the fab to scale 7nm production to 10k wafers/month.

14nm Quantum Dot Sensor Deposition (LAM 2300 UHV Advanced Series)

For a medium-sized fab producing 14nm quantum dot sensors via LAM 2300 UHV advanced deposition tools, LAM 810-801237-021 controls chamber pressure at 2×10⁻¹⁰ Torr ±1.5% during CdSe quantum dot growth. Its ultra-low outgassing design ensures quantum dot purity ≤0.05 ppb, eliminating “size variation” defects that previously affected 3.1% of wafers. The AI-based predictive maintenance feature detected a 3×10⁻¹² SCCM helium leak in the chamber seal, allowing technicians to replace the seal during a scheduled maintenance window—avoiding a 12-hour unscheduled downtime. Syncing with LAM 715-071309-001 (UHV Upgrade) (backside temp set to 90°C), the module adjusts vacuum to counteract thermal-induced pressure drifts—reducing quantum dot size variation from 8% to 2.3% and lifting sensor detection accuracy by 30%.

LAM 810-801237-021

Related Model Recommendations

LAM 810-801237-CAL: Advanced smart calibration kit exclusive to LAM 810-801237-021; Includes NIST-traceable UHV standards (1×10⁻⁴–1×10⁻¹⁰ Torr), AI-assisted triple-sensor calibration software, extends intervals to 36 months.

LAM 810-082745-003: UHV control module paired with LAM 810-801237-021; Syncs vacuum pressure across 7nm–14nm and 14nm–28nm mixed clusters, ideal for fabs with transitional workflows.

LAM 839-033075-001: UHV MFC synced with LAM 810-801237-021; 0–10 sccm range, ±0.3% accuracy, delivers sub-sccm gas flow to maintain extreme UHV stability.

LAM 853-015130-002-M-3609 (UHV Extreme Variant): Multi-channel UHV filter compatible with LAM 810-801237-021; Purifies aggressive gases (≤25% NF₃) to extreme UHV standards, preventing sensor contamination.

LAM 203-140148-308 (UHV Extreme Variant): Isolation valve paired with LAM 810-801237-021; 10 ms response time, handles extreme UHV flow, closes if pressure exceeds ±1.5% of setpoint or leak rate >1×10⁻¹² SCCM.

LAM 810-048219-019: 3nm-grade extreme UHV upgrade for LAM 810-801237-021; 3nm–7nm compatibility, AI-driven leak localization, suitable for fabs transitioning to cutting-edge nodes.

LAM 796-220745-001 (UHV Extreme Variant): RF module for LAM 7nm etch tools, works with LAM 810-801237-021 to adjust plasma power based on real-time extreme UHV pressure, enhancing etch selectivity.

LAM 856-010350-001 (UHV Extreme Variant): Multi-channel UHV manifold paired with LAM 810-801237-021; Distributes purified gases to 7nm multi-chamber clusters, ensuring uniform gas delivery.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing LAM 810-801237-021, confirm compatibility with your LAM extreme UHV tool (790 extreme etch/2300 UHV advanced/960 extreme UHV) and target gases (including ≤25% NF₃/CF₄). Power off the tool cluster and evacuate all chambers to ≤1×10⁻¹⁰ Torr (extreme UHV-grade evacuation) using a cryopump to avoid sensor contamination. Mount the module via titanium-alloy anti-vibration brackets (DIN rail/panel-mount), ensuring ≥25cm clearance from heat sources (e.g., high-power RF generators) and ≥20cm from other electronic components (to minimize EMI and ensure airflow). Connect vacuum lines: Use extreme UHV-grade 3/8” VCR fittings (electropolished, Ra ≤0.05 μm) for inlets (chamber pressure taps) and outlets (UHV throttle valves/turbomolecular pumps), torqued to 22 in-lbs ±0.5 in-lb with a UHV-calibrated torque wrench. For integration: Connect EtherNet/IP to LAM PCS v7.0+ and MES, RS-485 as backup, and digital I/O to high-precision MFCs/robots. Verify 24 VDC power (dedicated 3.5 A circuit with surge + voltage regulation) and perform a helium leak test (target ≤1×10⁻¹³ SCCM per chamber) before commissioning.

Commissioning Steps

Power on the module and initialize the AI calibration mode via LAM PCS v7.0+; the module will automatically detect connected sensors, valves, and pumps, and generate a custom calibration profile.

Test auto-range switching: Evacuate the chamber from 1×1