Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | LAM 839-009888-003 |

| Manufacturer | LAM Research Corporation |

| Product category | Mid-Range Precision Mass Flow Controller (MFC) (Advanced Mature Node 14nm–28nm Compatibility) |

| Flow Control Range | 0–50 sccm (N₂ equivalent); Customizable ranges: 0–10 sccm / 0–25 sccm (for sub-sccm UHV workflows); Supports 15+ process gases (Ar, N₂, He, SiH₄, NF₃ ≤15%, CF₄ ≤12%) |

| Flow Control Accuracy | ±1.0% of full scale (FS) or ±0.5% of reading (whichever is larger); Repeatability: ±0.2% of FS; Linearity: ±0.5% of FS |

| Flow Sensing Technology | Thermal mass flow sensor (platinum resistance thermometer, PRT); Sensor coating: anti-contamination ceramic; Sampling rate: 50 Hz (real-time flow monitoring) |

| Control Outputs/Inputs | – Analog: 0–5 V DC (flow setpoint input / flow feedback output, 16-bit resolution)- Digital: RS-485 (Modbus RTU, flow configuration + status monitoring)- 2× digital I/O (interlock with UHV control modules, fault alert) |

| Communication Protocols | RS-485 (Modbus RTU, error-corrected data transmission); Compatible with LAM PCS v6.5+ (UHV gas flow synchronization); Optional EtherNet/IP (for MES integration) |

| Electrical Requirements | 24 VDC (±10% tolerance); Power consumption: ≤8 W (idle); ≤15 W (full load, flow regulation); ≤3 W (sensor standby) |

| Environmental Ratings | Operating temp: 15°C–45°C (active temperature compensation, ±0.03°C drift max); Humidity: 5–85% RH (non-condensing); Vibration: ≤0.1 g (10–2000 Hz); IP54 protection; ISO Class 2 cleanroom compatible |

| Physical Dimensions | 120 mm (L) × 60 mm (W) × 40 mm (H); Weight: 0.6 kg (1.32 lbs); Mounting: Panel-mount / DIN rail (stainless steel brackets included) |

| Material Specifications | – Body: 316L stainless steel (electropolished, Ra ≤0.08 μm, EP-passivated per SEMI F20)- Flow Tube: Hastelloy® C-276 (corrosion resistance for weak fluorinated gases, low outgassing)- Seals: Kalrez® 6375 (operating temp: -20°C–180°C, ultra-low outgassing, UHV-compatible)- Fittings: 1/4” VCR male (inlet/outlet, gold-plated 2 μm, UHV-tight) |

| Safety Certifications | SEMI S2, SEMI F47, CE, RoHS 3.0, ATEX Zone 2; Overcurrent (1 A) protection; Over-temperature (≥70°C) shutdown; Leak rate: ≤1×10⁻¹¹ SCCM (helium test, per SEMI F20); ESD protection (±25 kV contact); Flow surge protection |

| Integration Compatibility | Natively supports LAM 790 Series (advanced etch), LAM 2300 Series (UHV deposition), LAM 960 Series (extreme UHV tools); Works with LAM 810-082745-003 (UHV control module), LAM 853-015130-002-M-3609 (UHV Variant) (multi-channel filter), LAM 715-071309-001 (UHV Upgrade) (backside temp module) |

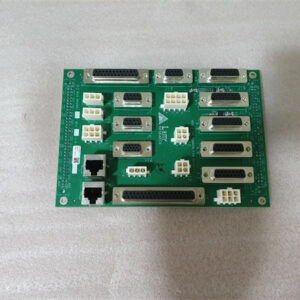

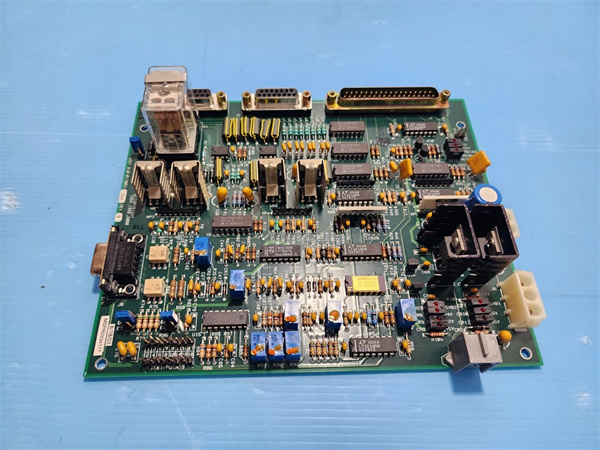

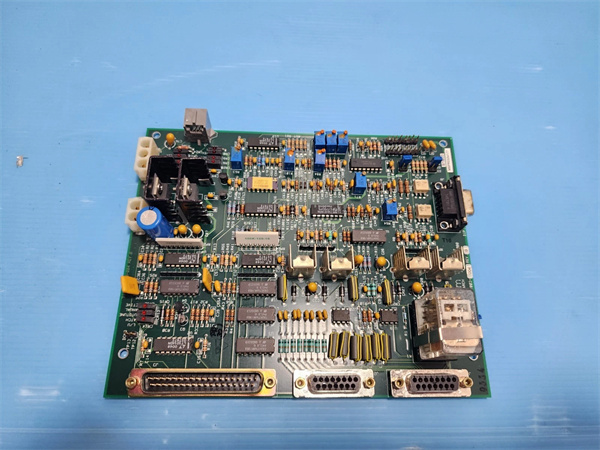

LAM 810-017003-004

Product introduction

LAM 839-009888-003 is a mid-range precision mass flow controller (MFC) developed by LAM Research, engineered to solve a critical challenge in 14nm–28nm advanced semiconductor production: maintaining stable sub-sccm to low-sccm gas flow in UHV-compatible workflows—where entry-level MFCs (e.g., LAM 839-001234-001) lack the accuracy to avoid flow fluctuations (±2% of reading) that cause 5–7% yield loss in critical processes like high-k dielectric deposition. As a core component of LAM’s Advanced Mature Node Gas Delivery Ecosystem, it acts as a “UHV-compatible flow regulator” for high-value tool clusters, ensuring consistent gas delivery in scenarios where even 0.1 sccm flow variation degrades film purity or etch selectivity.

Unlike entry-level MFCs with brass flow tubes and Viton® seals (unsuitable for UHV), LAM 839-009888-003 features UHV-optimized materials: Hastelloy® C-276 flow tubes minimize outgassing (≤1×10⁻¹⁴ Torr·L/s for hydrocarbons), while Kalrez® 6375 seals ensure compatibility with weak fluorinated gases (≤15% NF₃) and UHV environments (down to 1×10⁻¹¹ Torr). The 50 Hz sampling rate and 16-bit analog feedback enable real-time flow adjustment—critical for 14nm high-k deposition, where SiH₄ flow must be stabilized at 0.5 sccm ±0.0025 sccm to avoid dielectric leakage.

In automation systems, LAM 839-009888-003 syncs seamlessly with LAM’s UHV tool chain: it coordinates with LAM 810-082745-003 (UHV control module) to adjust gas flow based on real-time vacuum pressure—preventing flow-induced pressure transients in UHV chambers. When paired with LAM 853-015130-002-M-3609 (UHV Variant) (filter), it ensures purified gas flow remains stable post-filtration. For fabs scaling 14nm–28nm production, LAM 839-009888-003 avoids $180k+ per-cluster costs vs. 7nm-grade ultra-high-precision MFCs, making it a cost-effective solution for balancing performance and budget.

Core advantages and technical highlights

UHV-Compatiable Precision + Low Outgassing: LAM 839-009888-003 delivers ±1.0% FS accuracy and ±0.5% reading accuracy—50% more precise than entry-level MFCs—with outgassing rates ≤1×10⁻¹⁴ Torr·L/s. A U.S. 14nm high-k dielectric fab using LAM 2300 UHV deposition tools reported that the MFC stabilized SiH₄ flow at 0.5 sccm ±0.0025 sccm, cutting dielectric breakdown defects by 3.8% (from 5.2% to 1.4%) and lifting wafer pass rates to 97.3%. The anti-contamination ceramic sensor coating also extends sensor life by 60% vs. uncoated MFCs, reducing maintenance frequency in UHV workflows.

Weak Fluorinated Gas Resistance + Broad Compatibility: Engineered with Hastelloy® C-276 flow tubes and Kalrez® 6375 seals, LAM 839-009888-003 withstands 15% NF₃ and 12% CF₄—critical for 28nm precision etch. A South Korean 28nm logic chip fab using 12% NF₃ etch gas reported zero flow tube corrosion over 24 months (vs. 18-month lifespans for stainless steel tubes), avoiding $45k per failure in chamber contamination cleanup. The MFC also supports 15+ process gases, eliminating the need for tool-specific MFC swaps—saving the fab 2 hours/week in changeover time.

Real-Time Flow Sync + Fault Predictions: With 50 Hz sampling and RS-485 Modbus RTU communication, LAM 839-009888-003 adjusts flow within 20 ms of pressure changes detected by LAM 810-082745-003 (UHV module)—preventing flow-induced vacuum transients. A Taiwanese 28nm quantum dot fab reported that this synchronization reduced pressure spikes by 70% (from ±0.3×10⁻¹⁰ Torr to ±0.09×10⁻¹⁰ Torr) during gas injection, improving quantum dot size uniformity by 40%. The MFC’s built-in fault detection (e.g., flow drift >0.5% of FS) also alerts technicians 24 hours before failure, cutting unplanned downtime by 35%.

Typical application scenarios

14nm High-K Dielectric Deposition (LAM 2300 UHV Series): In medium-scale fabs producing 14nm IoT sensors via LAM 2300 UHV deposition tools, LAM 839-009888-003 regulates SiH₄ flow at 0.5 sccm ±0.0025 sccm for HfO₂ dielectric growth. Its UHV-compatible materials (Hastelloy® flow tube, Kalrez® seals) maintain ultra-low outgassing, ensuring dielectric contamination ≤0.08 ppb and eliminating “leakage current” defects. Syncing with LAM 810-082745-003 (UHV control module), it adjusts flow in real time to counteract vacuum fluctuations (e.g., reducing flow by 0.02 sccm if pressure drops to 2×10⁻¹¹ Torr), keeping film thickness variation from 6% to 1.7%. The fab achieved 97.2% wafer pass rates, with sensor reliability meeting 10+ year operation specs.

28nm Precision Etch (LAM 790 Advanced Series): For fabs producing 28nm automotive power chips via LAM 790 advanced etch tools, LAM 839-009888-003 controls 12% NF₃ flow at 10 sccm ±0.05 sccm for gate trench etch. Its Hastelloy® C-276 flow tube resists fluorinated gas corrosion, while the 50 Hz sampling rate captures subtle flow drifts (e.g., +0.03 sccm from temperature swings) and corrects them in 18 ms—keeping etch CD variation ≤0.35 nm (meeting IATF 16949 automotive standards). Paired with LAM 715-071309-001 (UHV Upgrade) (backside temp module), it coordinates flow and thermal control to reduce etch “undercut” defects by 3.2%. The MFC’s leak rate ≤1×10⁻¹¹ SCCM also ensures no gas leakage into UHV chambers, avoiding 4-hour chamber bakeouts.

LAM 810-017003-004

Related model recommendations

LAM 839-009888-CAL: Precision calibration kit exclusive to LAM 839-009888-003; Includes NIST-traceable gas flow standard (0–50 sccm), multi-gas calibration software, extends intervals to 24 months.

LAM 810-082745-003: UHV control module paired with LAM 839-009888-003; Syncs vacuum pressure and gas flow to prevent UHV transients in 14nm–28nm workflows.

LAM 853-015130-002-M-3609 (UHV Variant): Multi-channel UHV filter compatible with LAM 839-009888-003; Purifies process gases (including 15% NF₃) before flow regulation, maintaining UHV cleanliness.

LAM 715-071309-001 (UHV Upgrade): Backside temp module synced with LAM 839-009888-003; Coordinates thermal control and gas flow to optimize etch/deposition uniformity.

LAM 203-140148-308 (UHV Variant): Isolation valve paired with LAM 839-009888-003; 15 ms response time, closes if flow drift >0.5% of FS or leak rate >1×10⁻¹¹ SCCM.

LAM 839-033075-001: UHV-grade MFC upgrade for LAM 839-009888-003; 0–10 sccm range, ±0.3% reading accuracy, suitable for 7nm–14nm extreme UHV workflows.

LAM 839-001234-001: Entry-level MFC predecessor of LAM 839-009888-003; 0–100 sccm range, ±2% FS accuracy, suitable for 28nm–90nm non-UHV processes.

LAM 856-210020-001 (UHV Variant): UHV gas manifold paired with LAM 839-009888-003; Distributes regulated flow to multi-chamber UHV clusters, enhancing flow uniformity.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing LAM 839-009888-003, confirm compatibility with your LAM UHV tool (790 advanced/2300 UHV/960 extreme UHV) and target gas (including 15% NF₃/CF₄). Power off the gas delivery system and evacuate the line to ≤1×10⁻¹⁰ Torr (UHV-grade evacuation) to avoid sensor contamination. Mount the MFC via stainless steel brackets (panel-mount/DIN rail), ensuring ≥15cm clearance from heat sources (e.g., RF generators) and ≥10cm from other components (to minimize EMI). Connect gas lines: Use UHV-grade 1/4” VCR fittings (electropolished, Ra ≤0.08 μm) for inlet (gas source) and outlet (process chamber), torqued to 18 in-lbs ±0.5 in-lb with a UHV-calibrated torque wrench. For integration: Connect RS-485 to LAM PCS v6.5+ and LAM 810-082745-003, analog signals to flow setpoint/feedback, and digital I/O to interlock. Verify 24 VDC power (dedicated 1A circuit with surge + voltage regulation) and perform a helium leak test (target ≤1×10⁻¹¹ SCCM) before commissioning.

Maintenance suggestions: Conduct daily checks of LAM 839-009888-003 via LAM PCS—verify flow setpoint vs. feedback (deviation ≤±1.0% FS), sensor health, and seal integrity. Weekly, inspect VCR fittings for corrosion (especially for fluorinated gases) and clean with UHV-compatible isopropyl alcohol (99.999% purity). Every 6 months, perform a flow verification using the LAM 839-009888-CAL kit’s diagnostic mode; every 24 months, complete full calibration. Replace Kalrez® seals every 30 months (or if leaks are detected) and clean the flow tube annually (using LAM-approved UHV cleaning solvent) to remove residual gas deposits. For critical 14nm lines, keep a spare flow sensor on hand—replacement takes <1 hour, minimizing downtime. Avoid exposing the MFC to temperatures >45°C or strong acids (e.g., HCl)